Needle valves are indispensable for precision flow control in industrial systems. Whether in oil and gas, water treatment, or medical equipment, these valves ensure reliability and performance.

Needle valves control fluid flow precisely by using a small, tapered needle-like plunger. They are crucial for processes requiring accurate adjustments and leak prevention.

Understanding the key features, materials, and maintenance practices can help businesses make informed decisions and optimize their operations.

What are Needle Valves and Why are They Important?

Needle valves are small but powerful tools in flow control systems. They ensure smooth and precise adjustments in critical processes.

A needle valve works by gradually altering the orifice size using a needle-like plunger. This design ensures accuracy in controlling fluid flow rates.

These valves are particularly useful in high-pressure, low-flow applications across industries like oil and gas, water treatment, and medical devices.

The Role of Needle Valves in Industrial Systems

Needle valves offer unmatched precision compared to other valve types. Their ability to fine-tune flow rates makes them invaluable in sensitive operations, including:

- Oil and Gas: Managing high-pressure systems and preventing leaks.

- Water Treatment: Ensuring regulated flow for filtration processes.

- Medical Equipment: Providing precise fluid delivery in healthcare applications.

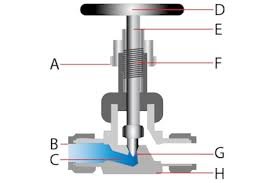

How Do Needle Valves Operate?

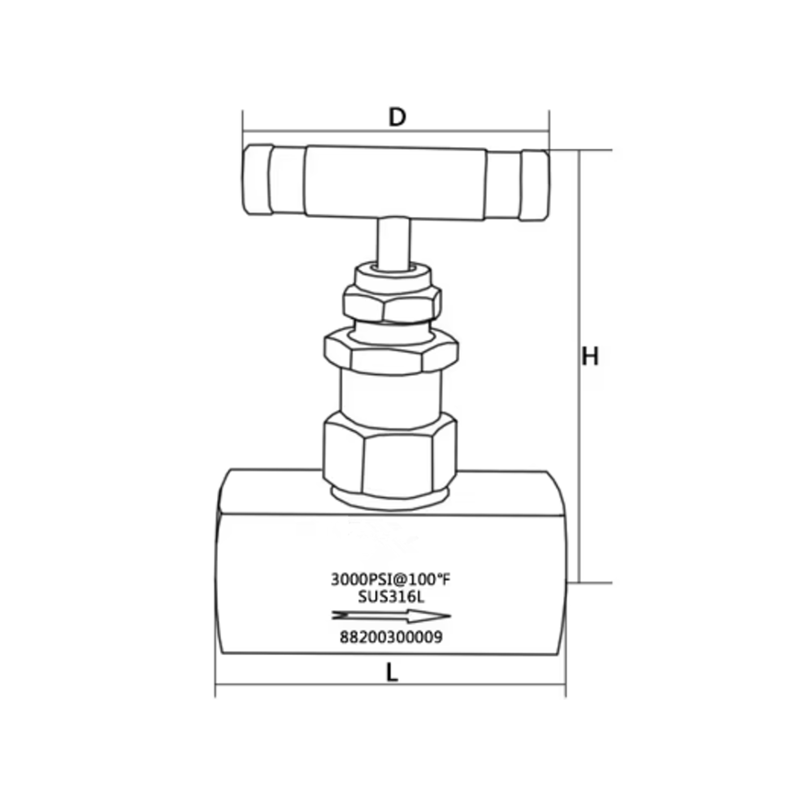

The design of a needle valve is simple yet effective. It features a slender, tapered needle that fits into a seat. By turning the handle, users can adjust the needle’s position, controlling the size of the orifice and the flow rate.

The gradual adjustment mechanism makes needle valves ideal for applications requiring minute flow changes.

Visualizing the Mechanism

- Needle: Controls the flow by varying the orifice size.

- Seat: Forms a seal to prevent leakage.

- Handle: Allows manual or automated control.

This precise mechanism ensures durability and prevents sudden pressure drops or fluid surges.

Materials and Their Performance Characteristics

The choice of material significantly impacts the valve’s performance in various environments. Common materials include stainless steel, brass, and specialized alloys.

Stainless steel offers high corrosion resistance, brass provides affordability, and alloys are best for extreme conditions.

| Material | Advantages | Limitations |

|---|---|---|

| Stainless Steel | High corrosion resistance | Higher cost |

| Brass | Affordable, easy to machine | Limited temperature resistance |

| Alloys (e.g., Monel) | Extreme durability and strength | Expensive, niche applications |

Selecting the right material depends on factors like pressure, temperature, and the fluid being transported.

Key Features and Benefits of Needle Valves

Needle valves are renowned for their precision and durability. These features make them indispensable in industrial applications.

Precision flow control, robust construction, and ease of maintenance are key benefits. These valves minimize leakage and extend system lifespan.

Advantages Breakdown

- Precision: Ideal for sensitive flow adjustments.

- Durability: Resistant to wear in demanding environments.

- Leak Prevention: Reliable seals prevent fluid or gas loss.

Investing in high-quality needle valves can enhance operational efficiency and reduce long-term costs.

Innovations and Emerging Technologies

The industry is evolving with innovations like smart needle valves and automated systems. These advancements are transforming traditional flow control mechanisms.

Smart needle valves enable remote monitoring and adjustments, improving system reliability and efficiency.

Cutting-Edge Features

- Automation: Reduces manual intervention.

- IoT Integration: Provides real-time performance data.

- Advanced Materials: Boosts longevity in extreme environments.

Adopting these technologies can help industries achieve greater efficiency and meet modern demands.

Common Challenges and Troubleshooting Tips

Despite their advantages, needle valves can encounter issues like leaks, wear, or improper installation.

Preventive maintenance and proper installation are critical to avoiding common problems. Regular checks extend the valve’s lifespan and ensure performance.

Common Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Leakage | Damaged seals or improper fit | Inspect and replace seals |

| Wear and Tear | Prolonged use | Schedule regular maintenance |

| Improper Installation | Misaligned components | Follow installation guidelines |

Proactive measures save time and prevent costly downtimes.

Case Studies and Real-World Applications

Examples from various industries highlight the versatility of needle valves. Their precision and reliability solve complex challenges.

Oil and Gas Industry

A refinery required precise pressure control to improve efficiency. By switching to high-performance needle valves, they reduced leakages and minimized downtime.

Medical Equipment

A healthcare provider used needle valves for accurate fluid delivery in dialysis machines, enhancing patient care through precision and reliability.

Installation and Maintenance Best Practices

Proper installation ensures optimal valve performance. Following a step-by-step guide reduces errors and enhances safety.

Install needle valves using appropriate tools and follow the manufacturer’s instructions. Regularly inspect and clean the valves to maintain performance.

Step-by-Step Installation

- Inspect the Valve: Check for defects before installation.

- Align Properly: Ensure correct orientation and alignment.

- Tighten Securely: Avoid overtightening to prevent damage.

Maintenance Schedule

| Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Cleaning | Bi-monthly |

| Seal Replacement | Annually or as needed |

Following these practices ensures consistent performance and extends the valve’s lifespan.

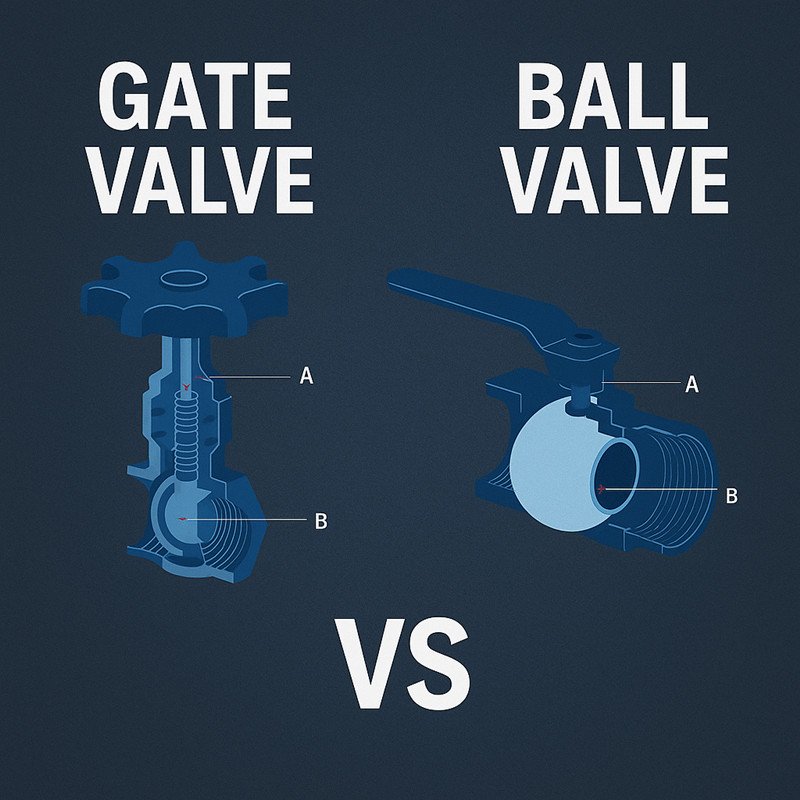

Comparison with Alternative Valve Types

Needle valves differ significantly from other valve types like ball or gate valves. Their unique design offers specific advantages.

Needle valves are superior for precision applications, while ball valves excel in on/off control and gate valves handle large flows.

| Valve Type | Best For | Limitations |

|---|---|---|

| Needle Valve | Precision flow control | Not suitable for high flow rates |

| Ball Valve | Quick on/off control | Limited precision |

| Gate Valve | Large flow volumes | Slow operation |

Choosing the right valve depends on the specific application requirements.

Conclusion

Needle valves are essential for precision applications across industries. By understanding their features, materials, and maintenance practices, businesses can optimize performance and achieve operational excellence.

For tailored solutions, choose high-quality needle valves that match your application needs. Reliable control starts with informed decisions.

FAQs

1. How to identify the right size and pressure rating?

Check system requirements and consult manufacturer guidelines.

2. How often should needle valves be maintained?

Perform regular inspections monthly and schedule comprehensive maintenance annually.

3. Can needle valves handle high pressures?

Yes, especially when made of materials like stainless steel or alloys.

Explore the possibilities with needle valves and unlock precision in your operations!