If your fluid control system requires absolute precision, needle valves may be the answer—but only if you choose the right one.

Needle valves are precision control devices1 that allow highly accurate regulation of flow in fluid systems, often used in high-pressure or critical applications.

They look simple on the outside, but a lot goes into their function, design, and performance. Let’s take a deep dive and uncover what makes needle valves a go-to choice in specialized industries.

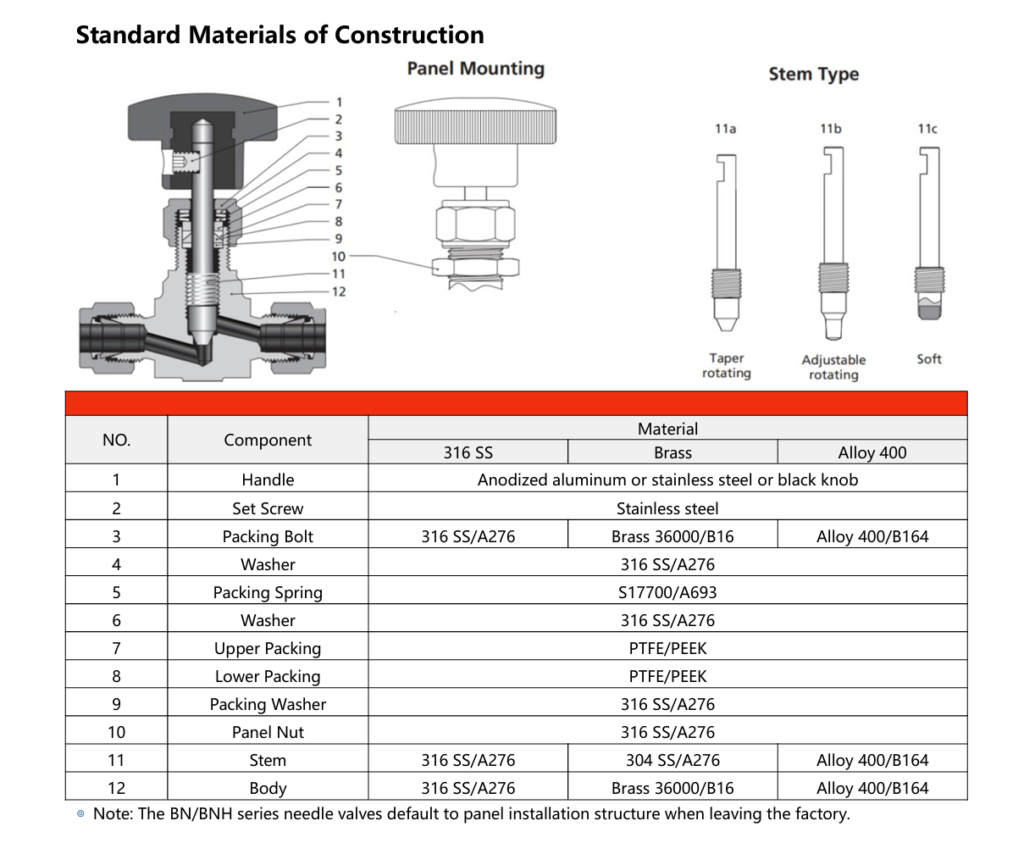

Anatomy of a Needle Valve: What Are the Key Components?

Needle valves seem compact, but they are engineered for fine control—every part has a purpose.

The key components of a needle valve include the valve body, stem, seat, handle, and packing, each playing a role in flow regulation.

Understanding these parts will help you evaluate valve quality and predict performance.

Valve Body

The body is the main housing. It holds all internal parts and connects to the pipeline. Materials like stainless steel, brass, or alloy steel are used depending on the working environment.

Stem and Needle

The stem is threaded and connected to a sharp needle-shaped plunger. As the handle turns, the needle moves up or down. It either allows or blocks the flow precisely at the seat.

Valve Seat

This is the sealing surface. The needle tip presses against the seat to shut off the valve. A well-machined seat ensures a tight seal, even under high pressure.

Handle

Handles are usually T-shaped or knurled for easy grip. Some valves include color-coded handles for system identification.

Packing

Packing materials like PTFE or graphite surround the stem to prevent leaks around the shaft. Good packing ensures durability and leak resistance under cycling conditions.

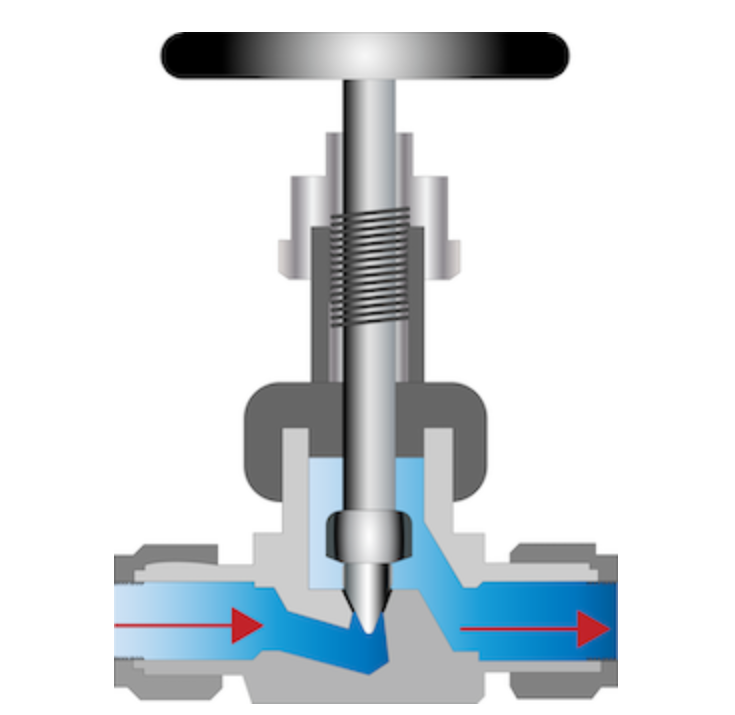

Operational Principles: How Do Needle Valves Work?

Controlling fluid flow is more than opening or closing a valve—it’s about precision.

Needle valves work by allowing gradual movement of a needle-shaped stem to adjust flow with fine resolution, making them ideal for precise control.

The mechanism is simple but highly effective.

Fine Control over Flow

Unlike ball valves that switch between open and closed, needle valves offer linear control. Each turn of the handle moves the needle incrementally, altering the flow path.

Laminar Flow and Small Orifices

The design includes a narrow orifice and long tapered needle. This allows for laminar flow, which means minimal turbulence and smoother regulation.

Suitable for Gases and Liquids

They work well for low flow rates, especially with gases or light fluids where control must be exact.

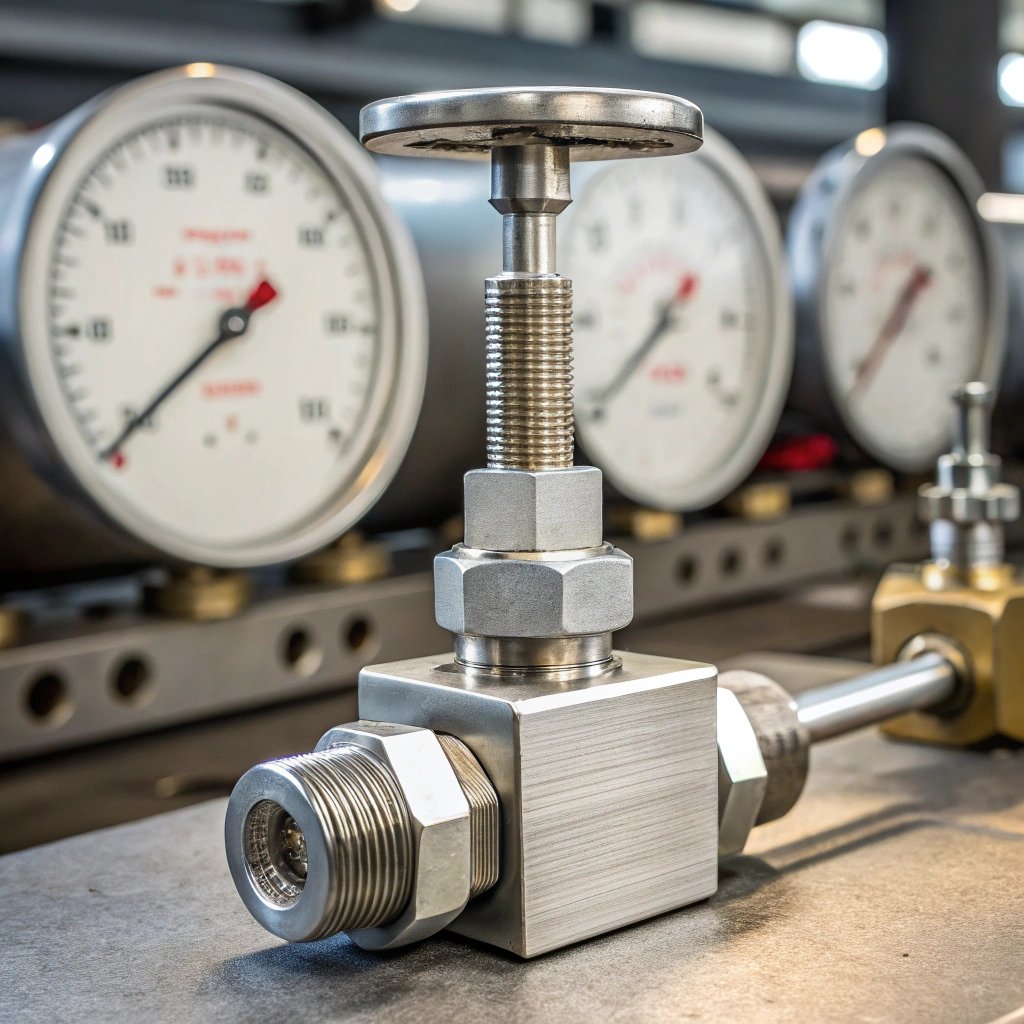

Material Selection and Construction: Why Does It Matter?

The working environment should dictate what your needle valve is made of.

Materials like stainless steel offer corrosion resistance, while brass is better for general use. Choose based on fluid type and conditions.

Material selection impacts safety, longevity, and performance.

Common Materials

| Material | Corrosion Resistance | Max Pressure | Cost |

|---|---|---|---|

| Stainless Steel | High | High | $$$ |

| Brass | Moderate | Medium | $$ |

| Alloy Steel | Medium | Very High | $$$$ |

| PVC/Plastic | Low | Low | $ |

Corrosion and Compatibility

Corrosive fluids can degrade brass or even stainless steel over time. Make sure the valve’s wetted parts match the chemical profile of your fluid.

Temperature and Pressure Ratings

For high-temperature and high-pressure environments, go for stainless steel with reinforced packing. PTFE works up to 204°C, while graphite can go beyond 500°C.

Performance Characteristics: How Do They Measure Up?

Not all needle valves are built the same—even if they look alike.

Flow coefficients (Cv), pressure ratings2, and temperature tolerances determine if a needle valve will perform reliably under specific conditions.

Let’s break it down.

Flow Coefficient (Cv)3

Cv is the flow rate (in gallons per minute) that passes through a valve with a 1 psi drop.

| Cv Value | Application Type |

|---|---|

| 0.1–0.5 | Precision gas control |

| 0.5–1.5 | Lab or instrumentation use |

| 1.5–5.0 | Industrial process control |

Small Cv = finer control. Larger Cv = more throughput.

Pressure Ratings

Some valves handle up to 6000 psi. Always match this to your system pressure plus a safety margin.

Temperature Tolerance4

Metal construction with proper packing allows operation from -54°C to 500°C, depending on material.

Types of Needle Valves: What’s the Difference?

Needle valves are not one-size-fits-all.

Straight, angle, and multi-turn needle valves vary by design and installation needs. Each serves a different purpose.

Straight Needle Valves

- Flow enters and exits in a straight line

- Compact and simple

- Ideal for small spaces

Angle Needle Valves

- Inlet and outlet at 90°

- Used when space is limited

- Reduces number of fittings needed

Multi-Turn Needle Valves

- More turns = finer control

- Great for ultra-precise flow regulation

- Common in labs and instrumentation

Applications Across Industries: Where Are Needle Valves Used?

Needle valves are everywhere—from laboratories to oil rigs.

They are commonly used in petrochemical, pharmaceutical, and food processing industries where accurate flow control is critical.

Let’s look at some use cases.

Petrochemical Plants

Used for controlling gas flow in high-pressure pipelines. Stainless steel versions resist corrosion from hydrocarbons.

Pharmaceutical Industry

Helps in metering solvents and reactive chemicals. Clean-in-place designs are used for hygiene.

Food and Beverage

Used for steam or fluid control. Sanitary designs with 316L stainless steel are common.

Installation and Maintenance Best Practices

Even the best valve won’t work if installed wrong.

Proper installation, routine inspections, and timely maintenance ensure long service life and reliable operation of needle valves.

Installation Tips

- Check valve orientation

- Use thread sealant or PTFE tape

- Don’t over-tighten connections

Maintenance Checklist

| Task | Frequency |

|---|---|

| Inspect seals and packing | Monthly |

| Clean internal components | Quarterly |

| Lubricate threads | As needed |

| Replace damaged handles | When worn |

Selection Criteria: How to Choose the Right Needle Valve?

With so many options, what should you focus on?

Base your needle valve choice on media compatibility, flow requirements, pressure ratings, and installation environment.

Key Selection Factors

- Fluid Type – corrosive, gas, or slurry?

- Flow Rate (Cv) – precision needed?

- Operating Pressure/Temp – extremes involved?

- Valve Configuration – straight or angle?

- Certifications – is traceability needed?

Choosing the right valve protects your system and ensures performance.

Innovations and Future Trends in Needle Valve Design

Needle valves are evolving to meet modern demands.

Recent innovations include low-emission packing, automated needle valves, and integration with digital control systems.

Key Advancements

- Low-Fugitive Emission Designs: Reduce greenhouse gas leaks

- Smart Valves: Bluetooth-enabled for remote adjustments

- Miniaturized Valves: For microfluidic systems

- 3D Printed Valves: Custom shapes and rapid prototyping

These developments will help companies automate, monitor, and optimize fluid control more efficiently.

Conclusion

Needle valves are essential for precision fluid control. Choose the right type, material, and features based on your system’s needs.

Frequently Asked Questions (FAQs)

1. What is the main advantage of a needle valve over a ball valve?

Needle valves allow for precise flow control, especially in low flow applications, whereas ball valves are better for quick shut-off. Needle valves are ideal when fine-tuning the flow is required.

2. Can needle valves handle high-pressure systems?

Yes. High-quality stainless steel needle valves can handle pressures up to 6000 psi or more, depending on their design and construction. Always check the manufacturer’s pressure rating before installation.

3. Are needle valves suitable for gas applications?

Absolutely. Needle valves are widely used in gas systems because they provide accurate control and tight shut-off, minimizing the risk of leaks. Ensure proper materials are used for gas compatibility.

4. How do I know if I need a straight or angle needle valve?

Choose a straight valve if your pipeline runs in a direct line. Use an angle valve when space is limited or when you need a 90-degree flow change without adding an elbow fitting.

5. What certifications should I look for when buying a needle valve?

Look for certifications like ISO 9001, CE, PED, or NACE depending on your industry. These indicate the valve has been tested for quality, pressure containment, and corrosion resistance.

-

Discover the importance of precision control devices in fluid systems to enhance your knowledge and application in critical industries. ↩

-

Knowing pressure ratings helps you choose a valve that can safely handle your system’s requirements, preventing failures. ↩

-

Understanding Cv is crucial for selecting the right needle valve for your application, ensuring optimal performance and control. ↩

-

Exploring temperature tolerances ensures you select a valve that operates reliably under your specific thermal conditions. ↩