Sanitary Butt Weld Fittings Supplier in China

- 15 + Years Manufacturer, based in China

- Trusted by global OEMs & valve wholesalers

- Custom Sanitary Butt Weld Fittings

- Fast delivery · Low MOQ · ISO 9001 Certified

Leading Supplier of Sanitary Butt Weld Fittings in China

Built for long-term reliability, ideal for high-pressure, high-temperature, and CIP/SIP applications, fully compliant with international standards.

At Beyond Fluid, we manufacture premium-quality butt weld sanitary fittings engineered for durability, corrosion resistance, and leak-free performance. Trusted by wholesalers, distributors, and OEMs worldwide.

Specification:

- Size: 1/2″-6″/DN10-DN150

- Weld Type: Butt Weld

- Material: SS316L/1.4404, SS304/1.4301

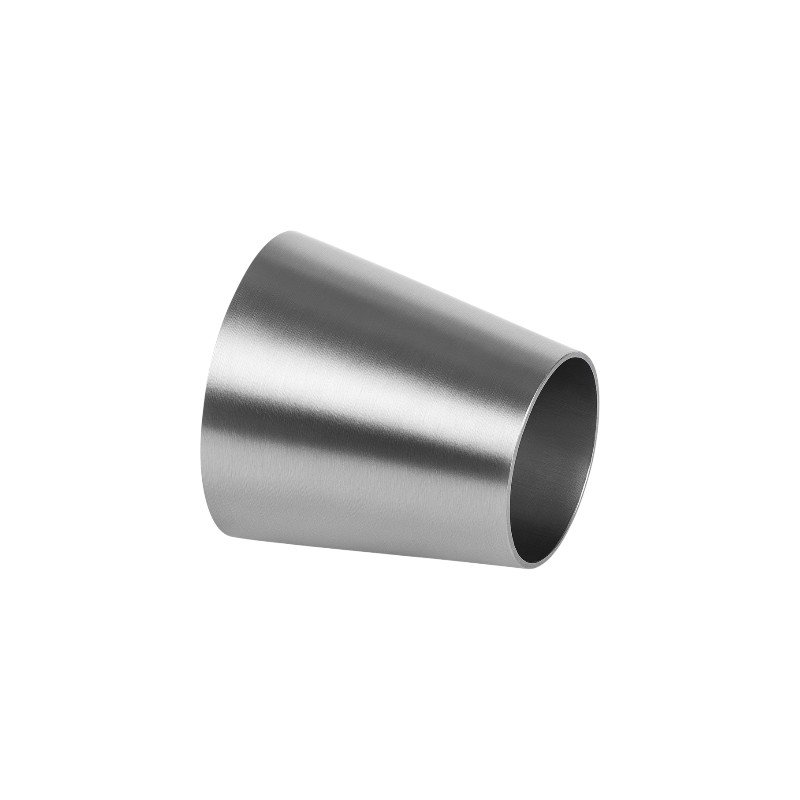

- Fittings Type: reducer, 45°&90° elbows, tee, Y tee

- Surface Finish: inside Ra ≤ 0.8 μm, outside Ra ≤ 1.6 μm

- Standard: 3A, ISO, DIN, SMS, BS, AMSE BPE

- Pressure Range: 150 psi (10 bar) to 300 psi (20 bar)

- Material Certificate: 3.1 material test certicate is available

Hot-Selling Types of Sanitary Weld Fittings

Connection: Butt Weld

Size: 1/2" – 6" / DN10 – DN150

Material: SS316L / 1.4404

Connection: Butt Weld

Size: 1/2" – 6" / DN10 – DN150

Material: SS316L / 1.4404

Connection: Butt Weld

Size: 1/2" – 6" / DN10 – DN150

Material: SS316L / 1.4404

Connection: Butt Weld

Size: 1/2" – 6" / DN10 – DN150

Material: SS316L / 1.4404

Connection: Butt Weld

Size: 1/2" – 6" / DN10 – DN150

Material: SS316L / 1.4404

Connection: Butt Weld

Size: 1/2" – 6" / DN10 – DN150

Material: SS316L / 1.4404

Connection: Butt Weld

Size: 1/2" – 6" / DN10 – DN150

Material: SS316L / 1.4404

Connection: Butt Weld

Size: 1/2" – 6" / DN10 – DN150

Material: SS316L / 1.4404

Sanitary Butt Weld Fittings

Sanitary butt weld fittings are a type of hygienic pipe connection commonly used in industries such as food & beverage, dairy, pharmaceutical, and biotechnology, where cleanliness and durability are critical.

Key Features

- Welded Connection: Instead of using clamps or threads, the fitting is welded directly to the pipe. This creates a smooth, crevice-free interior that reduces the risk of contamination.

- Hygienic Design: Because there are no gaps or dead spaces inside the connection, it prevents bacteria buildup and ensures safe, sanitary fluid transfer.

- Durability: Welded joints are strong, making them suitable for high-pressure and high-temperature applications.

- Standards Compliance: These fittings are manufactured to meet strict sanitary standards (such as 3A, ASME BPE, or ISO) for industries with regulated cleanliness requirements.

Applications of Sanitary Weld Fittings

| Application Area | Use |

|---|---|

| Food & Beverage | Dairy, juice, soft drinks, brewing, wine, and bottled water systems |

| Pharmaceutical & Biotechnology | Sterile fluid transfer, cleanroom piping, CIP/SIP processes |

| Dairy Processing | Milk collection, pasteurization, hygienic transport lines |

| Cosmetics & Personal Care | Production of creams, gels, and lotions under hygienic conditions |

| Chemical Processing | Corrosion-resistant fluid handling in sanitary systems |

| Brewing Industry | Fermentation tanks, transfer lines, and kegging systems |

Who We Are

Beyond Fluid, Your Reliable Sanitary Fittings Manufacturer

Beyond Fluid has over 15 years of experience supplying stainless steel instrument valves and fittings to wholesalers, distributors, and large contractors. We offer reliable quality, excellent service, on-time delivery, and competitive prices. Our commitment to advanced technology, precision engineering, and strict quality standards ensures we meet the diverse needs of customers worldwide.

We take pride in producing high-quality instrumentation valves and fittings. Our comprehensive range of products is designed for optimal performance and durability, with both standard and customized solutions. We aim to be your long-term trusted partner to expand your market presence.

Why Choose Us

Reliability. Consistency. Integrity

When you choose Beyond Fluid, you ensure precision and reliability, backed by our strict Quality Assurance Program.

Beyond Fluid ensures reliability with a 99.99% on-time delivery rate and quick response to urgent orders through stocked materials.

Our robust manufacturing and supply chain enable us to offer competitive prices, helping clients expand their market reach.

Our expert engineers offer design, CAD, and technical support, while our trained sales team ensures fast, efficient 24-hour responses.

Testimonials

What Our Clients Say

A Large Wholesaler From USA

“We’re literally satisfied with Beyond Fluid’ always on-time delivery and exceptional handling of requests. Their commitment to timely service is evident and consistently reliable. Their swift response and guaranteed on-time delivery make them my preferred choice.”

A Brand Manufacturer From Germany

“We can always count on Beyond Fluid’s quality. During a 2018 visit, their advanced facilities and stringent quality controls made a lasting impression on us. Their timely responses to requests for drawings or technical support further solidify my trust. We really love to place our orders to those suppliers like Beyond Fluid.”

FAQ

Frequently Asked Questions.

Here are a few real most popluar questions from our clients.

Sure, we can provide samples of instrument ball valves or fittings for evaluation firstly. Besides, we have the capaiblity to manufacture according to specific requirements.

Our typical payment term is 30% T/T in advance, balance payment against BL copy. But for serious buyers/companies, we’re open to discussing more flexible payment terms.