When it comes to valve selection, one wrong choice could disrupt your whole system, cost you time, or increase long-term maintenance expenses.

Butterfly valves are compact and economical, while ball valves offer better sealing and full-bore flow. Choosing the right one depends on your application, budget, and control requirements.

If you’re a technical buyer or engineer managing fluid systems, understanding the strengths and limits of each valve type will help you avoid common sourcing mistakes. Let’s break it down.

Quick Comparison Table: Butterfly vs Ball Valve?

This table simplifies key features like sealing, pressure, and cost to help you make fast comparisons.

Summary of Key Differences

| Feature | Butterfly Valve | Ball Valve |

|---|---|---|

| Flow Control | Moderate | Excellent |

| Pressure Drop | Medium | Low |

| Shut-off Capability | Good (resilient seat type) | Excellent (especially metal-seated) |

| Size Availability | Large diameters (cheaply) | Better for small-medium sizes |

| Installation Space | Compact | Bulkier |

| Maintenance | Easier for larger valves | Fewer parts, but harder in-line fix |

| Cost | Lower (especially at large sizes) | Higher upfront cost |

How Butterfly Valves Work?

Butterfly valves look simple, but they can cause system headaches if misunderstood.

A butterfly valve uses a rotating disc inside the pipe to control flow. When the disc aligns with flow, it’s fully open; when perpendicular, it’s shut.

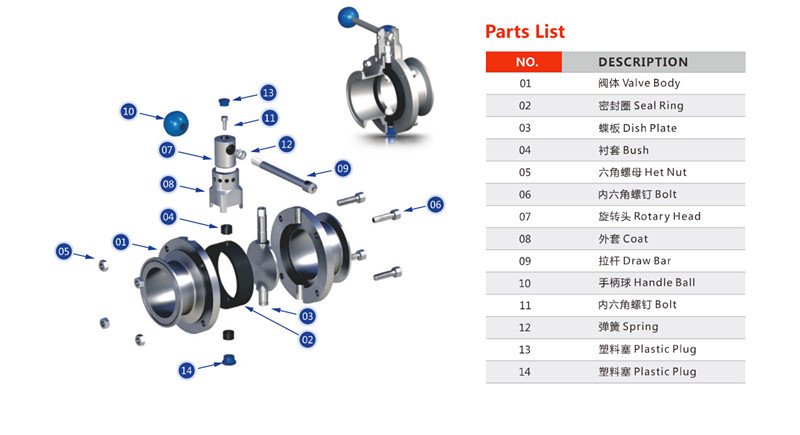

Basic Design and Components

- Disc

- Stem

- Seat (usually elastomer)

- Body (wafer, lug, or flanged)

How It Controls Flow

The disc rotates a quarter-turn for throttling or shut-off. It stays in the flow path, which causes pressure drop.

Typical Applications

- HVAC

- Water systems

- Irrigation

- Fire protection

Advantages and Limitations

Pros:

- Compact and lightweight

- Cost-effective for large diameters

- Fast operation

Cons:

- Less effective sealing under high pressure

- Flow always partially obstructed

- Not ideal for cleanliness-critical lines

How Ball Valves Work?

Ball valves are highly favored in critical shut-off applications.

They use a spherical ball with a bore to control flow. When the bore aligns with the pipe, flow is fully open.

Basic Design and Components

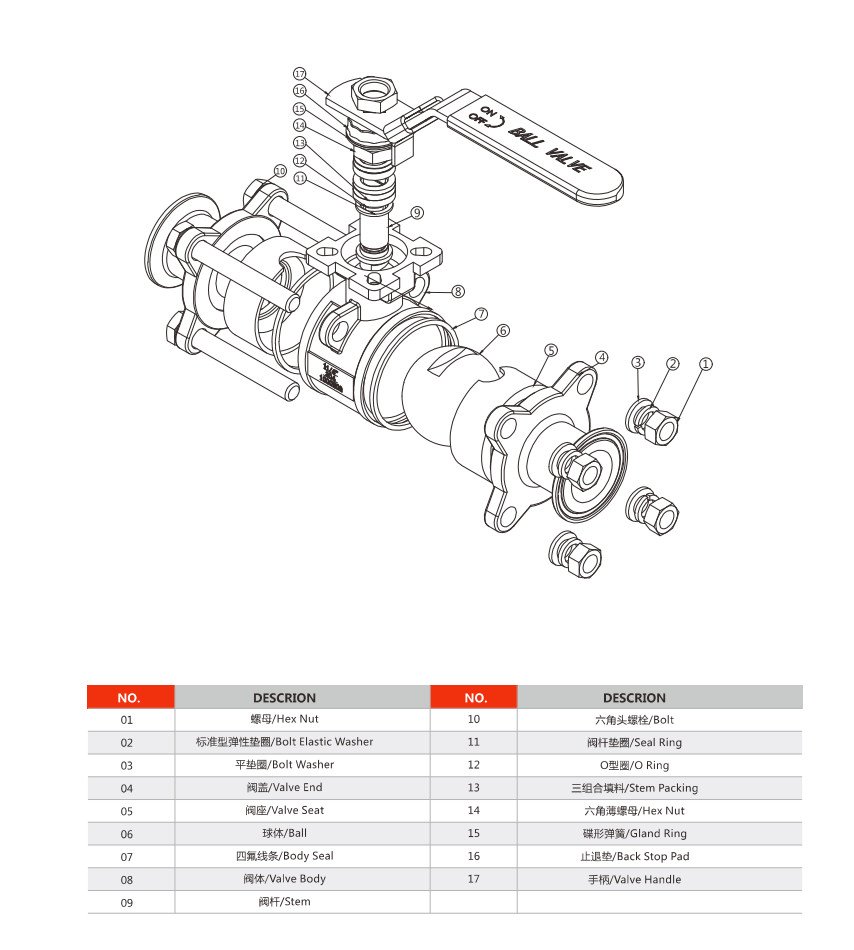

- Ball

- Seats (often PTFE or PEEK)

- Stem

- Body

- Handle or actuator

Flow Control and Full Port vs Reduced Port

- Full Port = No restriction

- Reduced Port = Smaller opening than pipe

Typical Applications

- Oil & gas

- Sanitary processing

- Chemical pipelines

- High-pressure water systems

Advantages and Limitations

Pros:

- Excellent sealing

- Durable and long service life

- Full bore for pigging

Cons:

- More expensive

- Larger and heavier

- Ball can seize if unused for long periods

Side-by-Side Comparison: Butterfly vs Ball Valve

Flow Performance and Pressure Drop

Ball valves = full flow, low resistance

Butterfly valves = disc causes some pressure loss

Seal Tightness and Leakage Control

Ball valves provide bubble-tight sealing

Butterfly valves rely on seat type (resilient or metal)

Installation Space and Weight

Butterfly valves are lighter and slimmer—especially above DN150

Ball valves take more room

Torque and Actuation

Butterfly valves need less torque

Ball valves need more powerful actuators

Cost Considerations

| Cost Factor | Butterfly Valve | Ball Valve |

|---|---|---|

| Initial Cost | Lower | Higher |

| Maintenance | Easier | Long-term stable |

| Automation Cost | Lower | Higher |

Pigging and Cleanability

- Ball valves are better for clean or sanitary lines

- Butterfly valves are not suitable for pigging

Size Availability and Scalability

- Butterfly valves scale better above 12"

- Ball valves dominate up to 6" or 8" systems

Selection Guide: How to Choose the Right Valve?

Consider: media, pressure, temperature, space, and maintenance.

Key Factors to Consider

| Factor | Ideal for Ball Valve | Ideal for Butterfly Valve |

|---|---|---|

| Tight shut-off | ✓ | |

| Space constraints | ✓ | |

| Corrosive media | ✓ (with SS/PTFE) | ✓ (lined types) |

| Budget-sensitive | ✓ | |

| Frequent cycling | ✓ | |

| Large bore systems | ✓ |

Valve Selector Checklist

- ❓ Do you need tight shut-off? → Ball valve

- ❓ Are you limited on space or weight? → Butterfly

- ❓ Is budget the top concern? → Butterfly

- ❓ Do you need sanitary or clean-in-place? → Ball

Common Mistakes to Avoid

- Selecting butterfly valve for sanitary line

- Ignoring torque requirement

- Forgetting maintenance access

- Using wrong valve for piggable systems

Application-Specific Advice

Food & Beverage / Sanitary Systems

Use ball valves with full port design. They’re easier to clean and don’t trap media. Pair with stainless tube fittings like our twin-ferrule systems.

Oil & Gas / Petrochemical

Use ball valves—especially fire-safe or metal-seated ones. Match with SAE or ISO adapters.

Water & Wastewater Treatment

Use butterfly valves—large size, low cost, and good for isolation duty.

HVAC and Building Systems

Use butterfly valves for chilled or condenser water, air handling, and fan coil systems.

High-Cycle or Automated Systems

Use ball valves with electric or pneumatic actuators. They offer repeatable shut-off and long lifespan.

Maintenance & Long-Term Performance

Common Issues and Failure Modes

| Valve Type | Typical Issues |

|---|---|

| Butterfly | Seat wear, misalignment |

| Ball | Stem seal failure, sticking ball |

Repairability and Spare Parts

- Butterfly = Easier seat change

- Ball = Harder to service in-line

Life-Cycle Cost Comparison

Ball valves = higher upfront but longer service

Butterfly = cheaper initially, may need earlier replacement

Material Advances

- PFA, PTFE, and PEEK seats

- Coated discs for longer wear

Energy Efficiency and Sustainability

Butterfly valves reduce actuator size and energy draw in big systems.

Frequently Asked Questions (FAQ)

Which is better for large diameter pipelines?

Butterfly valves. Less weight, cost, and easier to automate at large sizes.

Can butterfly valves provide tight shut-off?

Yes, high-performance types with double offset or triple offset can provide good sealing.

Are ball valves suitable for pigging?

Yes. Full port ball valves are ideal for piggable lines.

Which valve type is more cost-effective?

It depends. Butterfly valves are cheaper up front. Ball valves win in long-term maintenance and sealing.

Conclusion

Butterfly valves are compact and economical. Ball valves are robust and offer superior sealing. Choose based on your system’s fluid, pressure, cleanliness needs, and budget.

Beyond Fluid is a leading supplier of stainless steel sanitary valves for over 15 years, please contact us for more details.