Modern hygienic production demands fast, clean, and safe piping connections — but not every fitting can meet those needs. If you’re dealing with food, beverage, or pharma pipelines, you can’t afford contamination or leaks.

Tri‑Clamp fittings are the industry standard for sanitary, secure, and easy‑to‑clean piping connections in hygienic applications.

From brewery tanks to biotech bioreactors, these fittings offer the cleanability and modularity needed in industries where hygiene is non‑negotiable.

What are Tri‑Clamp (Tri‑Clover) fittings?

Tri‑Clamp fittings, also called Tri‑Clover fittings, are a type of sanitary connection widely used in food, beverage, pharmaceutical, and biotech industries. The name "Tri‑Clover" originated from Alfa Laval’s Tri‑Clover brand, one of the first to market the design. Today, the term is used generically across the industry.

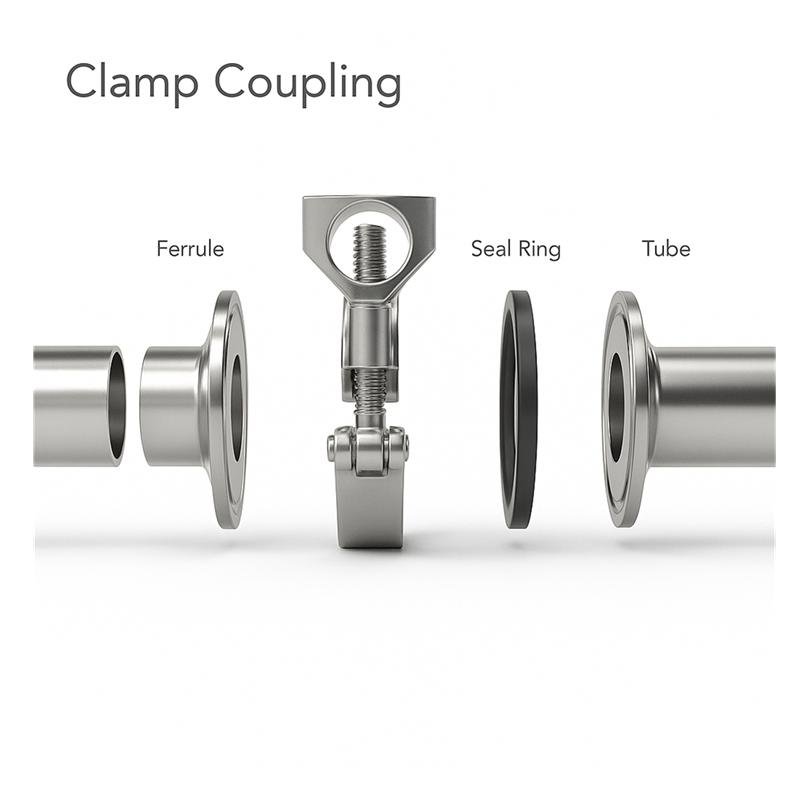

A Tri‑Clamp fitting consists of three main components: two ferrules (ends), a gasket, and a clamp to hold them together.

Once the ferrules are aligned with the gasket in between, the clamp locks them tightly, creating a secure, hygienic, and reusable connection.

Key Components

| Component | Function |

|---|---|

| Ferrules | Welded or attached to the ends of tubing or equipment |

| Gasket | Provides the sanitary seal, available in different materials |

| Clamp | Mechanically holds the ferrules and gasket together |

The clamp mechanism allows fast disassembly without tools, making it perfect for Clean‑in‑Place (CIP) and Sterilize‑in‑Place (SIP) systems.

Why use Tri‑Clamp fittings in hygienic processes?

Bacterial contamination, product hold-up, and cleaning inefficiencies are critical pain points in sanitary applications. Traditional threaded or flanged fittings often leave crevices or require tools — increasing downtime and contamination risk.

Tri‑Clamp fittings are designed with zero dead-legs, smooth internal surfaces, and fast assembly, making them ideal for strict hygienic standards.

Tri‑Clamp fittings offer several advantages:

Smooth interior and crevice-free seals

There are no threads inside a Tri‑Clamp joint. All wetted surfaces are polished to prevent product buildup. Gaskets sit flush with tubing, avoiding crevices where microbes can hide.

Easy cleaning (CIP/SIP)

Quick disassembly means faster changeover. Tri‑Clamp systems support automated CIP/SIP cycles with less cleaning agent waste. This minimizes water use and reduces cleaning time.

Material and size flexibility

Available in sizes from 0.5” to 12” and in materials like 304 and 316L stainless steel. PTFE and Viton gaskets support aggressive chemicals or high temps, making these fittings adaptable.

Long-term durability

Unlike threaded fittings, Tri‑Clamp connections don’t suffer from galling or thread erosion. When paired with the right gasket and proper torque, they provide decades of leak-proof service.

Applications and Industry Use-Cases

Sanitary fittings must serve multiple industries — all with different process needs. Tri‑Clamp systems are versatile across sectors.

Tri‑Clamp fittings are commonly used in food, beverage, and pharma, but they also serve cosmetic, biotech, extraction, and even semiconductor applications.

Real-World Applications

Food & Beverage

- Dairy: Pasteurizers and milk transfer lines

- Brewery: Fermentation and CIP skids

- Winery: Wine racking systems

Pharma & Biotech

- Bioreactors: Tri‑Clamp valves allow sterile sampling

- SIP lines: 316L and electropolished finishes meet ASME BPE

- Validation: Documented traceability and surface roughness (Ra < 0.5 µm)

Personal Care & Cosmetics

- Lotions, creams, and essential oils require sanitary, easy‑to‑flush systems.

Extraction, Semiconductor, and Water Treatment

- Cannabis extraction and solvent recovery systems use Tri‑Clamp under vacuum.

- High-purity water systems benefit from non-threaded, flush designs.

Materials, Finishes and Sanitary Standards

When it comes to hygienic piping, material choice directly affects product safety and process performance.

Tri‑Clamp fittings are typically manufactured in stainless steel grades 304 or 316L, with gaskets available in multiple elastomers or PTFE.

Material Options

Stainless Steel Grades

| Grade | Description | Best for |

|---|---|---|

| 304 | Economical, corrosion-resistant | General food applications |

| 316L | Molybdenum-added, low-carbon | CIP/SIP, pharma, aggressive chemicals |

Gasket Materials

| Material | Temp Range | Pros | Cons |

|---|---|---|---|

| Silicone | ‑50°C to 200°C | Flexible, inert | Poor chemical resistance |

| EPDM | ‑40°C to 150°C | CIP resistant | Not oil compatible |

| PTFE | ‑200°C to 260°C | Chemically inert | Stiff, prone to cold flow |

| Viton® | ‑26°C to 204°C | Excellent for oils | Not compatible with steam |

Surface Finish & Standards

- Ra ≤ 0.8 µm is standard for food-grade

- Ra ≤ 0.5 µm or electropolished required for biotech

- Certified to 3‑A, FDA, ASME BPE, or EHEDG

Sizing and Measurement: How to Choose the Correct Size

Tri‑Clamp fittings are sized by tubing OD (outside diameter), not the clamp size.

This leads to confusion when selecting sizes, as the clamp diameter is always larger.

Size Selection Tips

Common Mistake: Measuring the Clamp Ring

For example, a 1.5” Tri‑Clamp actually fits 1.5” tubing, but the clamp itself measures nearly 2” across. Always refer to tubing OD.

Common Tri‑Clamp Sizes

| Tri‑Clamp Size | Tubing OD (inches) | Ferrule Flange OD |

|---|---|---|

| 0.5” | 0.5” | 0.984” |

| 1.0” | 1.0” | 1.984” |

| 1.5” | 1.5” | 1.984” |

| 2.0” | 2.0” | 2.516” |

| 3.0” | 3.0” | 3.579” |

Always confirm compatibility with your existing tubing or valves.

Installation Best Practices & Maintenance

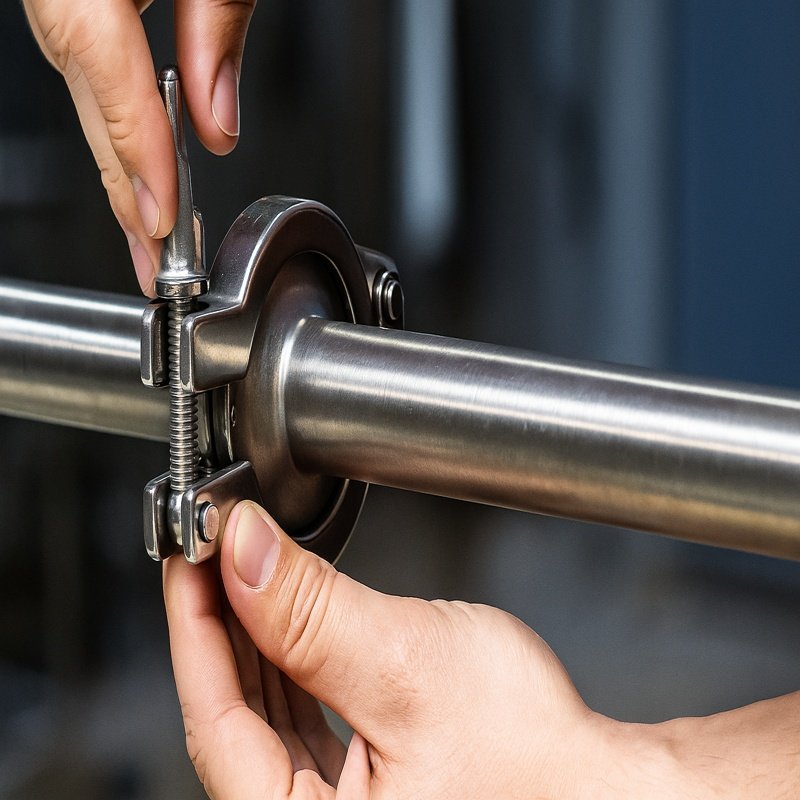

Poor installation can lead to leaks or contamination, especially if gaskets are pinched or ferrules misaligned.

Tri‑Clamp fittings must be properly aligned and torqued using appropriate gaskets and clamps.

Step-by-Step Installation

- Align two ferrules.

- Insert clean gasket between them.

- Place clamp over the flange lips.

- Tighten clamp manually or with calibrated torque (if specified).

Common Errors

- Overtightening: can deform gasket

- Misalignment: causes uneven seal

- Scratches on ferrules: promote bacterial growth

Maintenance Schedule

| Component | Frequency | What to check |

|---|---|---|

| Gaskets | Weekly | Cracks, swelling, hardening |

| Clamps | Monthly | Bent hinges or threads |

| Ferrules | Monthly | Surface scratches, pitting |

Replace gaskets after thermal cycles, or per CIP validation schedule.

Comparison with Other Sanitary Connection Systems

Tri‑Clamp is not the only hygienic fitting. So when should you use it — and when not?

Compared to I‑Line, DIN, butt‑weld, or threaded systems, Tri‑Clamp is faster to assemble but less suited for ultra‑high pressure or permanent installations.

System Comparison Table

| Type | Cleanability | Pressure | Assembly Speed | Cost | Use Case |

|---|---|---|---|---|---|

| Tri‑Clamp | Excellent | Medium | Very Fast | Medium | Modular, frequent cleaning |

| I‑Line | Excellent | High | Fast | High | Dairy, pharma |

| DIN 11851 | Good | Medium | Medium | Medium | EU food plants |

| Butt‑Weld | Best | Very High | Permanent | High | Critical pharma lines |

| Threaded | Poor | High | Slow | Low | Industrial, non-sanitary |

When NOT to use Tri‑Clamp?

- High-pressure (>10 bar) systems

- Permanent installations (butt-weld better)

- Extreme vibration environments

How to Specify Tri‑Clamp Fittings: Checklist for Engineers & Purchasers

Choosing the right fitting goes beyond diameter. Use this checklist.

Specification Checklist

- [ ] Media: What flows through it? (product, solvent, CIP chemical)

- [ ] Pressure / Temp: Max service range

- [ ] Tube OD: Match to process line

- [ ] Material: 304 vs 316L

- [ ] Gasket: EPDM, PTFE, silicone, etc.

- [ ] Finish: Polished or electropolished? Ra value?

- [ ] Certifications: 3A, FDA, ASME BPE, etc.

- [ ] Documentation: Material Test Certificate, traceability

- [ ] Supplier Capabilities: Custom bends, ferrule welding, polished assemblies

Conclusion

Tri‑Clamp fittings offer the perfect mix of hygiene, modularity, and reliability for clean industries. From biotech labs to breweries, they are the sanitary connection of choice.

Maximize process integrity by using the right material, gasket, and installation practices — and always source from a traceable, certified supplier.

Looking to specify Tri‑Clamp systems? Contact Beyond Fluid for expert support, spec sheets, and global shipment of stainless sanitary fittings.