Sanitary piping system1s are the backbone of the food, dairy, pharmaceutical, and biotech industries—but they’re only as good as the weakest link: the union.

Choosing the right hygienic union ensures cleanability, reduces downtime, prevents contamination, and extends system life. This guide walks you through all major union types, their comparisons, installation practices, and cost implications.

Whether you’re specifying a new line or upgrading legacy equipment, this guide helps you make better decisions and avoid expensive mistakes.

What Are the Main Types of Hygienic Tube Unions?

Sanitary unions may look similar on the surface, but their designs, standards, and usage vary greatly. Picking the wrong one can result in cleaning failure, poor fitment, or long downtimes.

The major hygienic union types include Tri-Clamp, DIN 11851, SMS, RJT, IDF, and flanged unions. Each has a unique design, standardization, and suitability for different regions and industries.

What Is a Tri-Clamp Union?

Tri-Clamp is the most globally recognized hygienic union—but is it the right fit for your application?

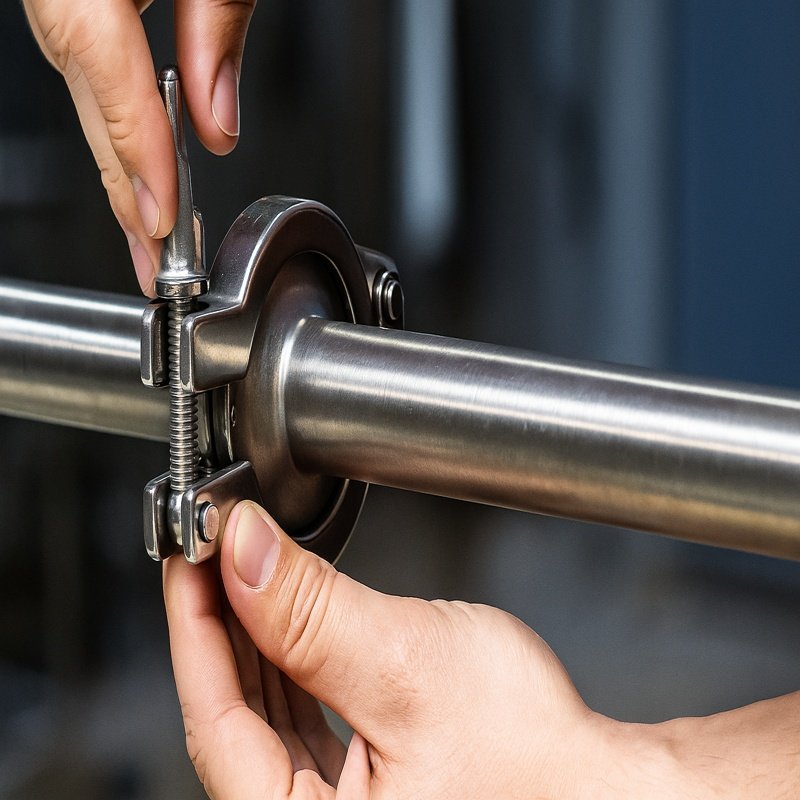

Tri-Clamp unions are composed of two ferrules, a gasket, and a clamp. They are designed for easy manual disassembly and are widely used in the food, beverage, and pharma sectors.

Key Specs & Use

| Attribute | Details |

|---|---|

| Standards | ASME BPE, ISO 2852, DIN 32676 |

| Region | Global |

| Pressure | Up to 16 bar |

| Temperature | -20°C to +150°C |

| Applications | Dairy, brewing, biotech, cosmetics |

| Cleaning | Excellent for CIP/SIP |

| Cost | Low to moderate |

| Material | Usually SS304 or SS316L |

Pros

- Easy tool-free assembly

- Widely available spares

- Suitable for frequent disassembly

- Compatible with most gasket materials (EPDM, PTFE, Viton)

Cons

- Can loosen under vibration

- Clamp misalignment risk if poorly installed

- Not ideal for very high-pressure systems

What Is a DIN 11851 Union?

DIN 11851 is a legacy European standard still dominant in certain markets.

DIN 11851 unions feature a male part, female nut, and a conical seal. The threaded design provides stronger sealing under higher pressures.

Key Specs & Use

| Attribute | Details |

|---|---|

| Standards | DIN 11851 |

| Region | Central Europe (Germany, Austria) |

| Pressure | Up to 25 bar |

| Temperature | Up to 150°C |

| Applications | Dairy, brewing, viscous liquids |

| Cleaning | Good with limitations (seal trap risk) |

| Cost | Moderate to high |

| Material | SS316L or higher |

Pros

- High mechanical strength

- Ideal for pressurized systems

- Available with hygienic design gaskets

Cons

- Threads can harbor bacteria

- Slower to disassemble

- Needs tools

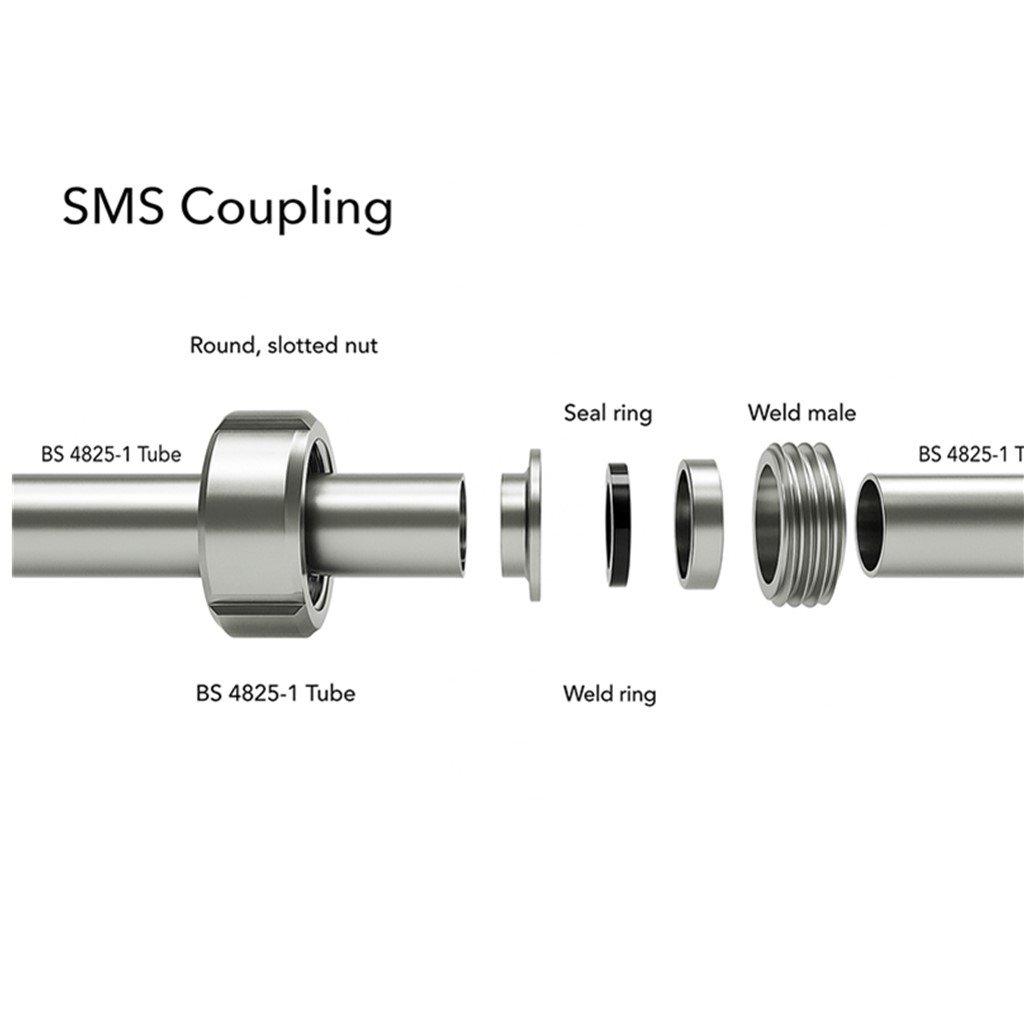

What Is an SMS Union?

Swedish standard, used across Scandinavian regions and often seen in legacy systems.

SMS unions have a simple nut and flat gasket seal arrangement. They are somewhat similar to DIN but have subtle dimensional and thread differences.

Key Specs & Use

| Attribute | Details |

|---|---|

| Standards | SMS 1145 |

| Region | Sweden, Norway, Finland |

| Pressure | Up to 16 bar |

| Applications | Beverage, water, plant-based production |

| Cleaning | Moderate |

| Cost | Moderate |

| Material | SS304 / SS316L |

Pros

- Compact design

- Moderate strength

- Widely stocked in Scandinavia

Cons

- Difficult to clean

- Regional standard; not widely used elsewhere

- Seal alignment is tricky

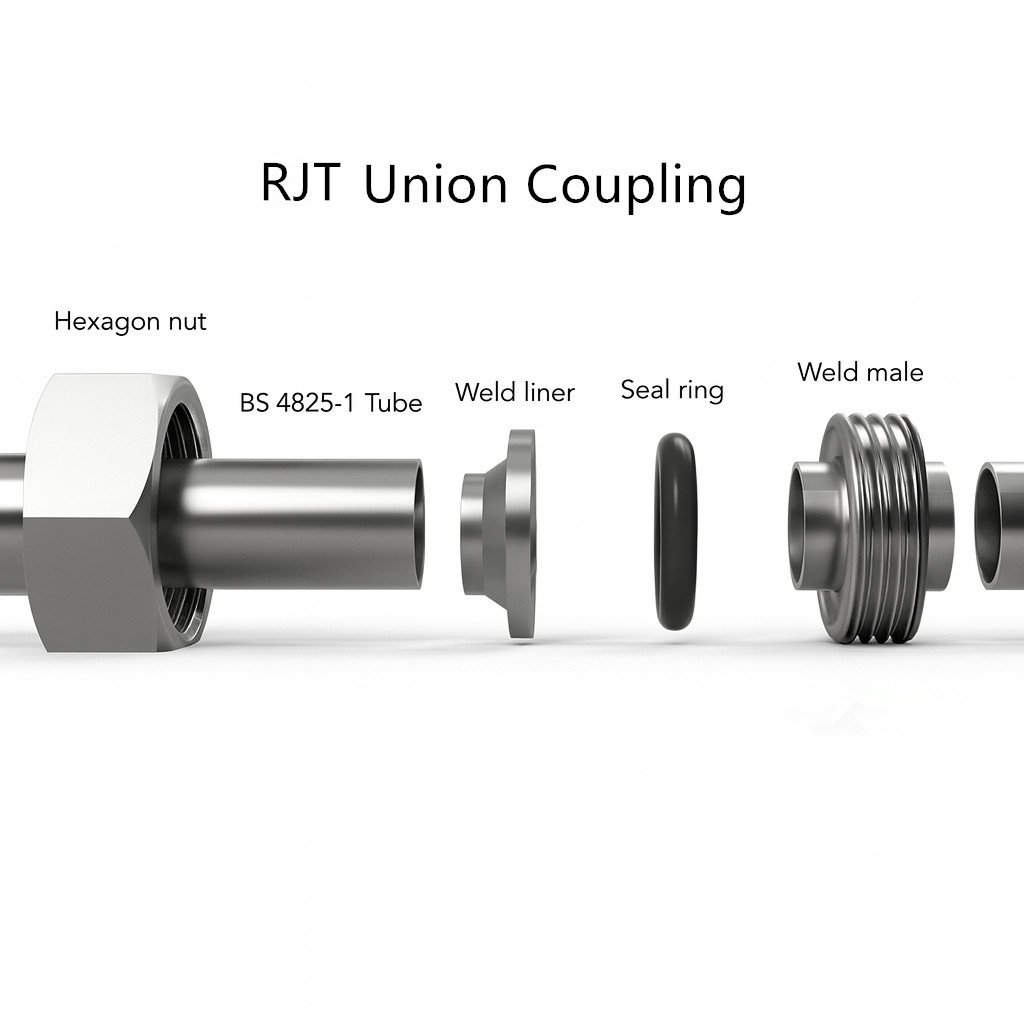

What Is an RJT Union?

Mostly used in the UK’s food and brewing sectors.

RJT (Ring Joint Type) unions include a male part, a hex nut, and a gasket seated in a recess.

Key Specs & Use

| Attribute | Details |

|---|---|

| Standards | BS 4825-5 |

| Region | UK & Ireland |

| Pressure | Up to 10 bar |

| Applications | Brewery, food plants, manual operations |

| Cleaning | Poor for CIP/SIP; better for manual cleaning |

| Cost | Low |

| Material | SS304, SS316 |

Pros

- Very common in older UK facilities

- Easy to fit with basic tools

- Low cost

Cons

- Threaded; hygiene risk

- Requires manual cleaning

- Not good under high pressure

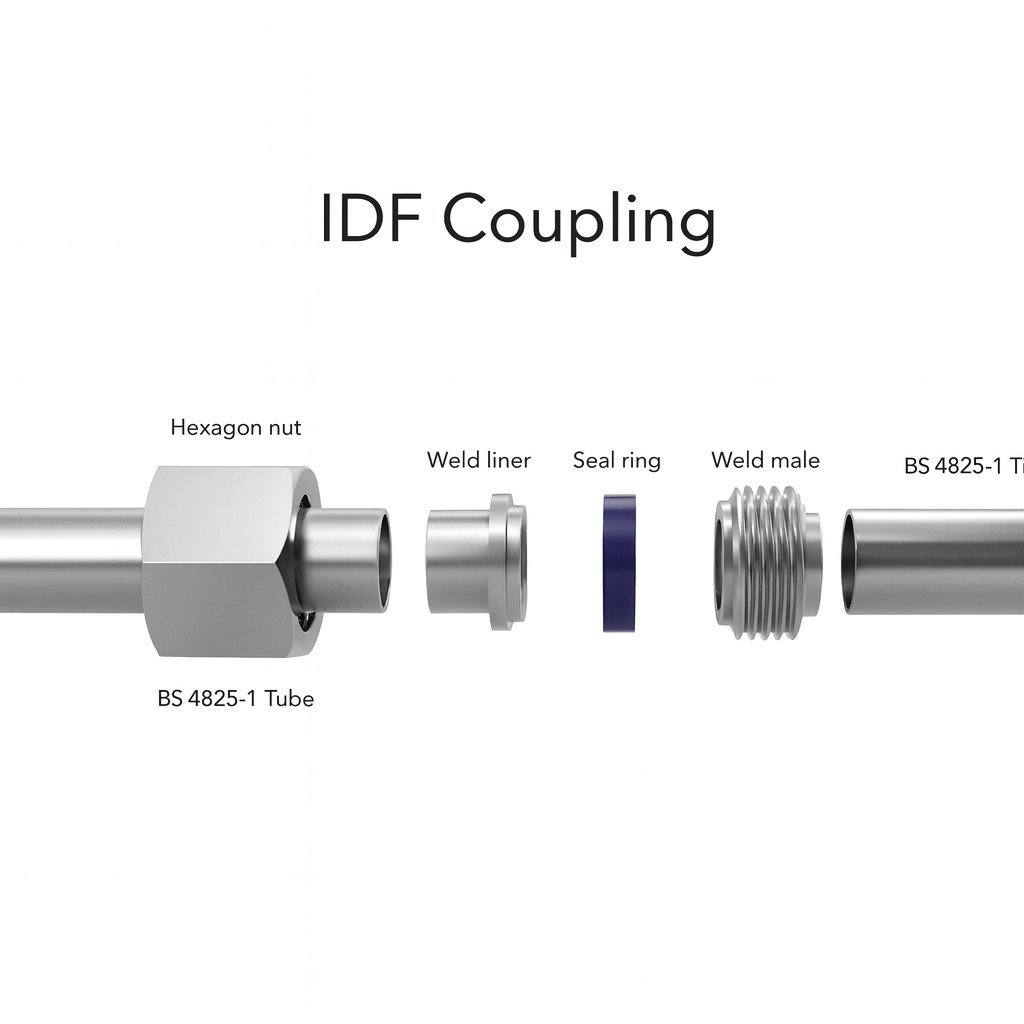

What Is an IDF Union?

IDF (International Dairy Federation) is similar to RJT but with better hygiene focus.

The IDF union minimizes crevices and is smoother internally, making it more suitable for clean-in-place applications than RJT.

Key Specs & Use

| Attribute | Details |

|---|---|

| Standards | ISO 2853 |

| Region | International (dairy focus) |

| Pressure | 6–10 bar |

| Applications | Dairy, milk plants |

| Cleaning | Good CIP compatibility |

| Cost | Moderate |

| Material | SS316L, EPDM/PTFE gasket |

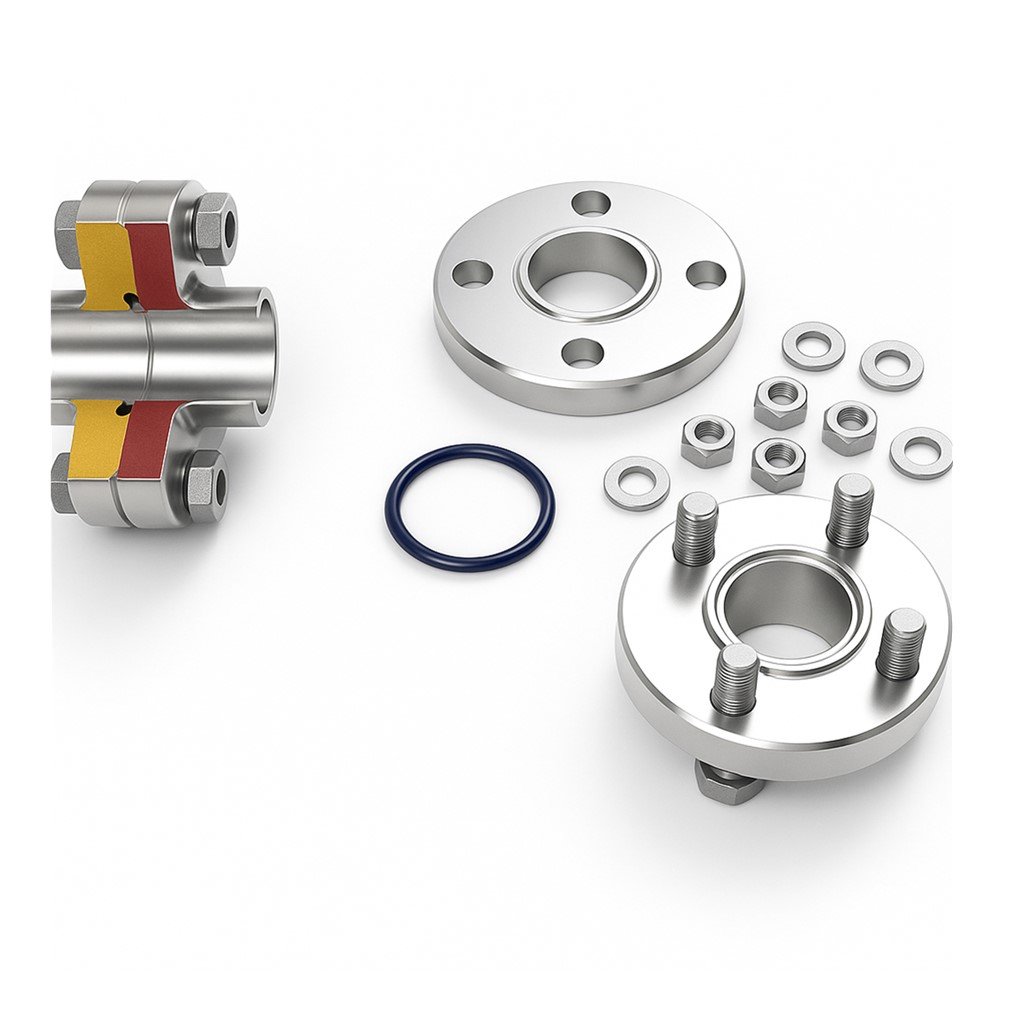

What About Flanged Hygienic Connections?

Used in large-bore piping or where pipe stress is a concern.

Flanged unions involve bolt-tightened connections using flat or grooved gaskets. They are often used in pharma or high-viscosity transfer lines.

| Attribute | Details |

|---|---|

| Standards | ASME BPE, ISO 1127 |

| Region | Global |

| Pressure | Up to 40 bar |

| Cleaning | Good with high-grade finishes |

| Cost | High |

| Material | SS316L, Duplex |

How to Select the Right Hygienic Union?

System design starts with asking the right questions.

Choose a union type based on pressure, temperature, cleaning method, material compatibility, regional norms, and future serviceability.

Comparison Table

| Union Type | Pressure (bar) | Cleaning | Cost | Tool-free? | CIP Ready? | Typical Regions |

|---|---|---|---|---|---|---|

| Tri-Clamp | 16 | Excellent | $$ | Yes | Yes | Global |

| DIN11851 | 25 | Good | $$$ | No | Moderate | Central EU |

| SMS | 16 | Fair | $$ | No | No | Scandinavia |

| RJT | 10 | Poor | $ | No | No | UK |

| IDF | 10 | Good | $$ | No | Yes | Global |

| Flanged | 40 | Excellent | $$$$ | No | Yes | Global |

Decision Tree

| Decision Point | Condition | Recommended Union |

|---|---|---|

| Is pressure > 16 bar? | Yes | DIN 11851 or Flanged Union |

| No | Continue | |

| Is frequent disassembly required? | Yes | Tri-Clamp |

| No | Continue | |

| Regional Standard Preference | System is in the UK | RJT |

| System is in Germany/Austria | DIN 11851 | |

| System is in Sweden/Finland/Norway | SMS | |

| Industry Application | Dairy Processing | IDF |

Installation, Cleaning & Maintenance Best Practices

Bad installations cause contamination, leaks, and downtime.

Each union has unique installation and maintenance requirements—here’s what to watch for.

General Best Practices

- Always torque to spec. Over-tightening ruins gaskets.

- Use correct seal type.

- Check alignment before clamping.

- Replace gaskets after wear or thermal fatigue.

Seal Life vs. Cleaning Cycles

| Gasket Material | Typical CIP/SIP Cycles |

|---|---|

| EPDM | 100–150 |

| PTFE | 200+ |

| Silicone | 75–120 |

| Viton | 100–200 |

Lifecycle Cost & Spare Strategy

A cheap union can become costly over time.

Total cost of ownership includes downtime, cleaning labor, gasket costs, and spare inventory.

Example: Tri-Clamp vs DIN 11851

| Item | Tri-Clamp | DIN 11851 |

|---|---|---|

| Initial Cost | $ | $$ |

| Cleaning Time | 5 min | 10 min |

| Downtime Risk | Low | Moderate |

| Spare Parts | Universal | Specialized |

| Gasket Cost | $ | $$ |

Emerging Trends in Hygienic Connections

Hygienic design is evolving fast.

New manufacturing techniques and materials are enhancing performance and reducing environmental impact.

- 316L to Duplex steel

- Additive manufacturing for custom unions

- ASME BPE 2023 updates: smoother finishes, lower Ra

- Sealing tech: longer-life elastomers, better compression control

Conclusion

Choose your union as carefully as your pump or valve—it’s critical to your process.

Use this guide to compare options, prevent issues, and save cost across the system lifecycle.

Beyond Fluid is a leading supplier of stainless steel sanitary union fittings for over 15 years in China, please contact us for more details.

Appendix

Glossary

- CIP: Clean-in-place

- SIP: Sterilize-in-place

- Ferrule: Tube end used in union connection

- IDF: International Dairy Federation

- Tri-Clamp: Quick-release clamp connection

Quick Reference Table

| Standard | Region | Common Use |

|---|---|---|

| DIN11851 | Central Europe | Dairy, pharma |

| SMS 1145 | Scandinavia | Food, beverage |

| RJT | UK | Brewing |

| IDF | Global | Dairy |

| ISO 2852 | Global | General sanitary use |

| ASME BPE | Global | Biotech/pharma |

-

Explore this resource to learn essential maintenance tips that ensure the efficiency and safety of your sanitary piping system. ↩