Sanitary processes demand fast, secure, and hygienic piping connections. But traditional fittings often create cleaning bottlenecks and contamination risks.

Tri-clamp fittings, also known as sanitary clamp fittings or Tri-Clover® fittings, are quick-assembly connectors designed for easy cleaning and hygienic fluid transfer in sanitary industries.

Whether you’re working in a brewery, a biotech lab, or a dairy plant, tri-clamp fittings let you connect and disconnect lines fast — with minimal risk of leaks or microbial growth.

What Are Tri-Clamp Fittings?

Sanitary production can be a headache when connectors are hard to disassemble, clean, or inspect.

Tri-clamp fittings (or Tri-Clover® fittings) are sanitary-grade mechanical joints that consist of three main parts: ferrule, gasket, and clamp.

They create a crevice-free seal that resists contamination. This makes them ideal for hygienic process lines where frequent disassembly and sterilization are required.

What Are They Also Called?

- Sanitary clamp fittings: highlights their use in food/pharma

- Tri-Clover® fittings: originally a trademark (now widely used generically)

- Hygienic clamp fittings: common in biotech

- Tri-clamp connections: most widely used term in North America

Material Selection & Specification Considerations

Choosing the correct material and finish isn’t just about price — it’s about preventing corrosion, ensuring compatibility, and meeting compliance standards.

Tri-clamp components are typically made from 304 or 316L stainless steel. Surface finish, pressure/temperature resistance, and regulatory compliance also influence specification.

Stainless Steel Grades

| Grade | Composition Highlights | Use Case |

|---|---|---|

| 304 | Cr/Ni, general purpose | Low-acid food/beverage systems |

| 316L | Adds molybdenum, low carbon | High corrosion, CIP/SIP cycles |

| 316Ti | Titanium stabilized variant | Heat resistance, pharma-specific |

Surface Finish

- Ra value: Roughness average; smoother = more hygienic

- Food grade: Ra < 0.8 µm

- Pharma grade: Ra < 0.38 µm (often electropolished)

- Electropolishing: Enhances corrosion resistance and cleanability

Pressure & Temperature Ratings

- Typical clamps: Up to 10 bar / 150 psi

- Gasket materials affect temperature range:

- Silicone: -50°C to 200°C

- EPDM: -40°C to 150°C

- PTFE: -80°C to 250°C

Fluid Compatibility

- PTFE: Inert for aggressive chemicals

- EPDM: Good for water, not for oils

- Viton: Handles oils, not steam

- Always check gasket/fluid compatibility for FDA use

Size Standards

- OD-based sizing (Outer Diameter)

- Common sizes: 0.5", 1", 1.5", 2", 3", 4"

- Check for ASME BPE, ISO 2852 standards

Compliance

- FDA CFR 21: For food-contact gaskets

- 3-A Sanitary Standard: For dairy systems

- USP Class VI: Biocompatibility for pharma/biotech

- ASME BPE: U.S. biopharmaceutical processing standard

Why Do Tri-Clamp Fittings Matter in Sanitary Process Industries?

Buildup, biofilm, and cross-contamination from poor piping design can compromise entire batches.

Tri-clamp fittings are essential in sanitary industries because they simplify maintenance, support modular design, and reduce microbial risks.

In regulated sectors like food, beverage, cosmetics, and pharma, cleaning speed and validation are critical. Tri-clamp assemblies are ideal because they:

Ensure Hygienic Design

- Crevice-free interface minimizes bacteria traps

- Compatible with CIP (Clean-in-Place) and SIP (Sterilize-in-Place)

Speed Up Maintenance

- Tool-free disassembly

- Gaskets are easy to replace

Support Modular Systems

- Quickly swap filters, valves, sensors

- Easy to scale production up/down

What Industries Use Tri-Clamp Fittings?

Cleaning delays, residue, and faulty seals cost money and compromise product.

Tri-clamp fittings are the gold standard for hygienic connection in industries where cleanliness and fast maintenance are crucial.

Common Applications

| Industry | Typical Applications | Common Materials | Typical Size Range | Temp/Pressure |

|---|---|---|---|---|

| Food & Beverage | Dairy, juice, flavor systems, bottling lines | SS316L, PTFE | 1" to 4" | -10 to 150°C / 10 bar |

| Brewery & Winery | Fermentation tanks, CIP loops, bottling | SS304, EPDM | 1.5" to 3" | -10 to 130°C / 6 bar |

| Pharmaceutical & Biotech | Bioreactors, filtration skids, WFI lines | 316L electropolished | 0.5" to 2" | -20 to 200°C / 10 bar |

| Cosmetics & Personal Care | Lotion mixing, fragrance filling | SS316, Silicone | 1" to 2.5" | -5 to 100°C / 5 bar |

| Water Treatment | Chemical dosing, RO skids | SS304, EPDM | 1" to 4" | -10 to 90°C / 6 bar |

What Are the Components of a Tri-Clamp System?

Even a basic tri-clamp joint can go wrong if you’re unclear on how the parts work together.

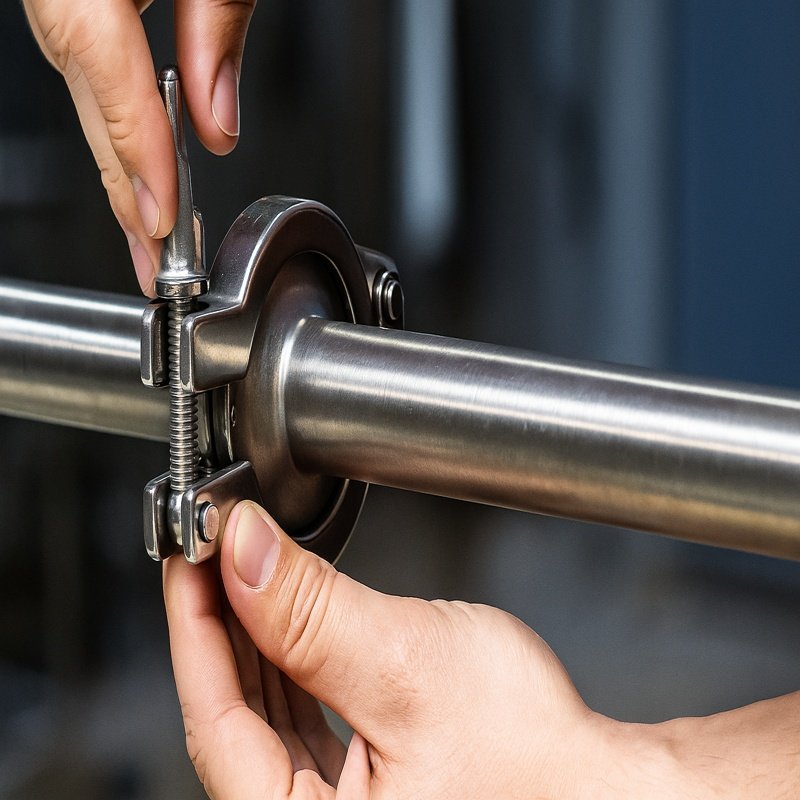

A tri-clamp assembly is made of three key parts: ferrule (weld end), clamp (mechanical force), and gasket (sealing). Many accessory types exist for specific layouts.

Core Components

- Ferrules: Tube ends with sanitary flange, either butt-weld or threaded

- Clamps: Apply pressure to seal the gasket between ferrules

- Gaskets: Elastomeric or PTFE seals, in various hardness and temperature grades

Common Accessories

- Caps: Seal open ports

- Elbows (90°, 45°): Route flow direction

- Tees/Crosses/Wyes: Flow splits

- Reducers: Transition between pipe sizes

- Adapters: NPT, hose barb, or compression fitting ends

- Clamps: Single-pin, double-pin, ASME, high-purity

- Gaskets: Silicone, EPDM, Viton, PTFE, etc.

Glossary

| Term | Meaning |

|---|---|

| Ferrule | Sanitary flange welded to tube |

| Clamp | Metal ring that applies sealing pressure |

| Gasket | Sealing element compressed between ferrules |

| 14WMP | Weld short ferrule |

| 13MHHM | Heavy-duty clamp |

| 40MP | End cap with clamp end |

(See appendix for full designation list)

How to Choose the Right Tri-Clamp Fitting?

Wrong gasket. Poor weld. Loose clamp. These small mistakes lead to leaks and contamination.

Choosing the right tri-clamp fitting requires matching pipe OD, fluid type, pressure/temp, and cleaning method to the right ferrule, clamp, and gasket.

Step-by-Step Selection Process

- Measure tube OD (not ID)

- Match ferrule type (short weld, extended, threaded)

- Select clamp type (standard, ASME, high-pressure)

- Pick gasket material based on fluid, temp, and CIP/SIP method

Factors to Consider

- Flow rate (affects pipe size)

- Compatibility with fluid (chemical or biological)

- Pressure and temperature

- Cleaning method: CIP/SIP vs manual disassembly

- Finish: for pharma, Ra < 0.38 µm, electropolished

Common Pitfalls to Avoid

- Mismatched ferrule and clamp sizes

- Using EPDM gasket with high-temp steam

- Installing clamps too tight or too loose

- Creating "dead legs" where fluid stagnates

Conclusion

Tri-clamp fittings offer safe, hygienic, and fast connection for fluid systems in regulated industries. Choosing the right components and maintaining them properly reduces downtime, improves product quality, and supports compliance.

Beyond Fluid is a leading supplier of sanitary tri-clamp fittings for over 15 years. Please click here and learn more about fittings types.