Sanitary systems often fail due to something as small as a wrongly sized Tri-Clamp — causing leaks, contamination, or shutdowns.

Tri-Clamp sizing is critical in brewing and sanitary systems because incorrect sizing can cause leakage, hygiene issues, and increased maintenance costs.

If you’re unsure which size Tri-Clamp to use, or if you’ve ever ordered the wrong part, this guide is for you. Let’s simplify everything from basic definitions to advanced system upgrades.

What is a Tri-Clamp (Tri-Clover) Connection?

Brewers and food engineers hate disassembling pipework for cleaning. That’s why Tri-Clamps became the go-to.

Tri-Clamps, also known as Tri-Clover fittings, are sanitary connectors made for quick assembly and disassembly in hygienic systems.

Components of a Tri-Clamp Fitting:

- Ferrules: Welded to the end of a tube or equipment port.

- Gasket: Provides the sanitary seal.

- Clamp: Locks the connection together.

Why is it preferred?

- Smooth interior for no fluid retention.

- No threads in contact with the product.

- Quick disassembly for cleaning or reconfiguration.

How Is Tri-Clamp Size Defined?

A 1.5" clamp is not 1.5 inches wide. Confused? You’re not alone.

Tri-Clamp nominal size refers to the outside diameter (OD) of the tube, not the flange.

Common Sizing Table

| Tube OD | Flange OD | Clamp Size |

|---|---|---|

| 1/2″ | 0.984″ | 3/4″ Clamp |

| 3/4″ | 0.984″ | 3/4″ Clamp |

| 1″ | 1.984″ | 1.5″ Clamp |

| 1.5″ | 1.984″ | 1.5″ Clamp |

| 2″ | 2.516″ | 2″ Clamp |

| 2.5″ | 3.047″ | 2.5″ Clamp |

| 3″ | 3.579″ | 3″ Clamp |

| 4″ | 4.682″ | 4″ Clamp |

Metric vs Imperial Confusion

Tri-Clamps are sized using the Imperial system, but many global suppliers list metric OD. Always confirm:

- Tube OD (inches or mm)

- Ferrule flange OD

- Whether you’re working with DIN or ISO dimensions

How to Measure and Verify Size?

Use calipers or tape to measure the outer diameter (OD) of the tubing — not the flange.

Step-by-Step:

- Use a caliper or tape.

- Measure the OD of the tube, not the clamp or ferrule.

- Compare against a Tri-Clamp sizing chart.

Mistakes to Avoid:

- Measuring the flange instead of tube OD.

- Assuming clamp size = tube size.

- Not accounting for pipe wall thickness.

Clamp Style Selection

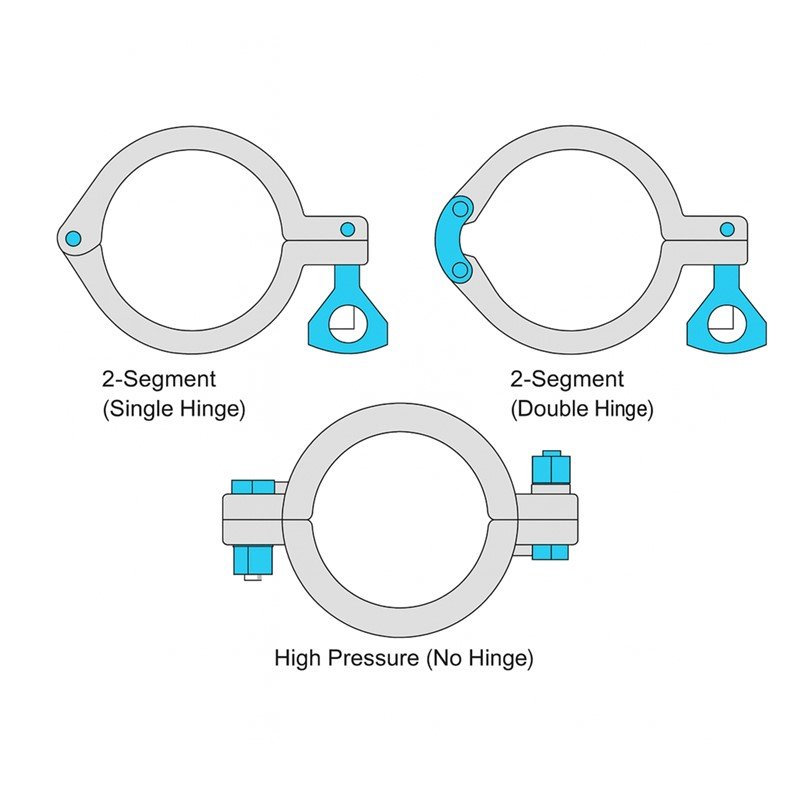

We offer three main types of Tri-Clamp fitting clamps to suit various applications:

-

Single-Hinge (2-Segment) Clamp

This is the most cost-effective and widely used clamp. Its simple, single-hinge design makes it reliable for standard applications where frequent access is needed. -

Double-Hinge (2-Segment) Clamp

This design features two hinges, providing greater flexibility and easier installation in tight or awkward spaces. While it shares a similar pressure rating with the single-hinge version, we offer this style in limited quantities based on customer demand. -

High-Pressure Bolted Clamp (No Hinge)

Designed for high-pressure or semi-permanent installations, this clamp comes in two separate segments that are bolted together using a brass nut and lock washer. Brass is specifically used to prevent galling and seizing when paired with stainless steel bolts. This style is ideal where safety and sealing performance are more important than frequent disassembly.

| Size | Single Hinge (13MHM) – 70F | Single Hinge (13MHM) – 250F | Double Hinge (13MHHM‑DP) – 70F | Double Hinge (13MHHM‑DP) – 250F | High Pressure (13MHP) – 70F | High Pressure (13MHP) – 250F | High Pressure (13MHP) – Max Torque |

|---|---|---|---|---|---|---|---|

| 3/4 in. | 1500 | 1200 | 1500 | 1200 | 1500 | 1200 | 130 In Lbf |

| 1.5 in. | 500 | 250 | 500 | 250 | 1500 | 1200 | 130 In Lbf |

| 2 in. | 450 | 250 | 450 | 250 | 1000 | 800 | 130 In Lbf |

| 2.5 in. | 400 | 200 | 400 | 200 | 1000 | 800 | 130 In Lbf |

| 3 in. | 350 | 150 | 350 | 150 | 1000 | 800 | 130 In Lbf |

| 4 in. | 200 | 125 | 200 | 125 | 800 | 600 | 200 In Lbf |

| 6 in. | 150 | 75 | 150 | 75 | 300 | 200 | 200 In Lbf |

| 8 in. | 100 | 50 | 100 | 50 | 250 | 150 | 200 In Lbf |

| 10 in. | 40 | 30 | — | — | 200 | 125 | 200 In Lbf |

| 12 in. | 30 | 25 | — | — | 150 | 100 | 200 In Lbf |

What Materials and Gaskets Should I Choose?

Stainless steel ferrules with silicone or EPDM gaskets are best for breweries.

Ferrule & Clamp Materials:

- SS304: Cost-effective, good for most applications.

- SS316L: Resistant to corrosion, ideal for CIP chemicals.

Gasket Materials:

| Material | Temp Range | Use Case |

|---|---|---|

| Silicone | -40°C to 230°C | General use, flexible |

| EPDM | -50°C to 150°C | Alkaline CIP systems |

| PTFE | -200°C to 260°C | High temp, inert |

3-A Sanitary Certification is a must for food-grade processes in the US.

Key Standards for Tri-Clamp Fittings

Several key standards define the dimensions and performance of Tri-Clamp fittings used in sanitary applications.

Common Standards:

| Standard | Region | Description |

|---|---|---|

| ISO 20371 | International | Stainless steel sanitary tubes standard, commonly used globally. |

| DIN 326762 | Europe | German/European standard for hygienic clamp fittings. |

| BS 4825-33 | UK | British sanitary ferrule sizing and tolerance guide. |

| 3-A Sanitary4 | USA | Sanitary design and safety standards for food and pharma equipment. |

Conclusion

Tri-Clamp sizing isn’t rocket science — but it can make or break your brewery’s performance.

Use the right tools, check sizing charts, and always verify tube OD before ordering.

For custom stainless steel Tri-Clamp fittings or adaptors, visit Beyond Fluid — your trusted source for ISO 8434 and 3-A compliant parts.

Beyond Fluid – Stainless Steel Sanitary Fittings Manufacturer in China.

-

Explore this link to understand the global standards for stainless steel sanitary tubes, ensuring quality and safety in various applications. ↩

-

Explore this link to understand the importance and specifications of DIN 32676 in ensuring hygiene in food and pharmaceutical industries. ↩

-

Explore this link to understand the BS 4825-3 standard, crucial for ensuring compliance in sanitary applications in the UK. ↩

-

Discover the 3-A Sanitary standards to learn about essential safety and design guidelines for food and pharmaceutical equipment. ↩