Introduction

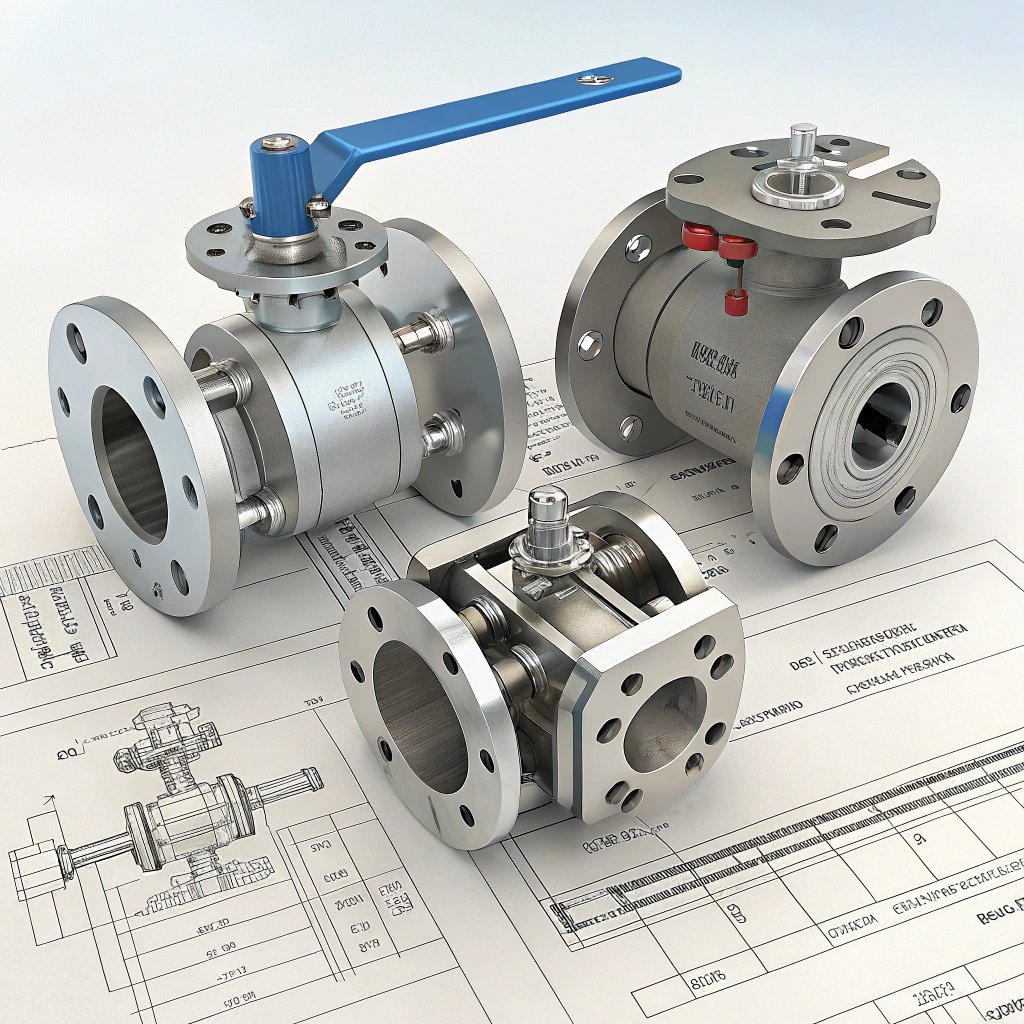

Ball valves are essential components in fluid control systems1, offering reliable shutoff and flow regulation. They are widely used across various industries due to their durability and efficiency.

This article provides a detailed analysis of different ball valve structural types, their mechanisms, advantages, and industry-specific applications.

Choosing the right ball valve type is crucial for ensuring optimal performance, longevity, and cost-effectiveness in industrial applications.

Overview of Ball Valves

Ball valves are quarter-turn valves that regulate flow using a spherical disc with a hole through its center. When aligned with the pipeline, fluid flows freely; when turned 90 degrees, the flow stops.

Ball valves are popular due to their quick operation, tight sealing, and versatility, making them ideal for a range of industries including oil and gas, water treatment, and pharmaceuticals.

Ball valves provide excellent shutoff capabilities2 and can handle high pressures and temperatures with minimal leakage.

Detailed Classification of Ball Valves by Structural Types

Floating Ball Valves

Floating ball valves have a freely suspended ball held in place by the seat rings. The fluid pressure pushes the ball against the downstream seat, ensuring a tight seal.

They are ideal for low to medium-pressure applications and provide effective sealing with minimal operational torque.

Key Features:

- Simple design with easy operation

- Cost-effective compared to trunnion-mounted valves

- Suitable for small to medium-sized pipelines

Common Applications:

- Water distribution

- Chemical processing

- HVAC systems

Trunnion-Mounted (Fixed) Ball Valves

These valves feature a ball supported by trunnions, reducing excessive movement and enabling operation under high-pressure conditions.

They offer superior performance in high-pressure and large-diameter pipelines, ensuring lower torque requirements and enhanced durability.

Advantages:

- Handles high-pressure systems efficiently

- Lower operational torque reduces actuator size

- Reliable sealing under extreme conditions

Applications:

- Oil and gas pipelines

- Power plants

- Petrochemical industries

Elastic (Flexible) Ball Valves

Elastic ball valves incorporate a flexible seat that allows for improved sealing under fluctuating pressures.

These valves are best suited for applications with variable pressures, providing reliable sealing and enhanced durability.

Key Benefits:

- Adaptability to varying conditions

- Reduced wear and tear

- Effective sealing for high-cycle applications

One-Piece Ball Valves

One-piece ball valves have a solid, single-body construction, reducing potential leak points.

They are cost-effective but not serviceable, making them ideal for non-critical, low-maintenance applications.

Features:

- Simple, robust design

- Lower cost but non-repairable

- Suitable for basic on/off applications

Two-Piece Ball Valves

Two-Piece ball valves consist of two separate components, allowing for easier maintenance while maintaining durability.

They offer a balance between cost and serviceability, making them widely used in various industries.

Three-Piece Ball Valves

Three-piece ball valves allow for easy disassembly, making them perfect for applications requiring frequent cleaning or maintenance.

Their modular design makes them the preferred choice for industries with strict hygiene or operational requirements.

Top-Entry Ball Valves

Top-entry ball valves allow maintenance without removing the valve from the pipeline.

They are commonly used in industries where inline maintenance is critical.

Welded Body Ball Valves

Fully welded ball valves provide leak-proof operation, making them suitable for harsh environments.

These valves are ideal for buried or high-pressure applications where reliability is paramount.

Comparative Analysis of Ball Valve Types

| Valve Type | Pressure Handling | Maintenance | Cost | Best Application |

|---|---|---|---|---|

| Floating Ball | Low to Medium | Moderate | Low | Water, Chemicals |

| Trunnion-Mounted | High | Moderate | High | Oil & Gas, Power Plants |

| One-Piece | Low | None | Low | Basic shutoff needs |

| Two-Piece | Medium | Easy | Medium | Industrial pipelines |

| Three-Piece | Medium | Easy | High | Food, Pharmaceuticals |

| Welded Body | High | None | High | High-pressure environments |

Selection Criteria for Ball Valves

Key Factors to Consider

- Application Requirements: Flow control, shutoff, or throttling.

- Material Compatibility: Stainless steel, brass, or plastic, depending on the media.

- Pressure and Temperature Ratings: Ensure compatibility with the operating environment.

- Maintenance Needs: Determine if inline serviceability is required.

Industry-Specific Applications

Oil and Gas Industry

- High-pressure and high-temperature resistance

- Suitable for large pipelines and offshore operations

Chemical Processing

- Corrosion-resistant materials for handling aggressive chemicals

- High durability for continuous operation

Water Treatment

- Reliable shutoff for fluid regulation

- Long lifespan and minimal maintenance

Pharmaceuticals & Food Industry

- Hygienic design for sterile environments

- Compliance with industry regulations

Future Trends in Ball Valve Technology

Innovations and Advancements

- Smart Ball Valves: Integration with IoT for real-time monitoring

- Advanced Coatings: Improved corrosion resistance and longevity

- Eco-Friendly Designs: Sustainable materials and energy-efficient mechanisms

Conclusion

Selecting the right ball valve type is crucial for ensuring efficient and reliable fluid control3. Understanding structural differences4 helps industries choose the best-suited valve for their needs, optimizing performance and cost-effectiveness.

-

This resource will give you insights into fluid control systems, helping you grasp the importance of components like ball valves in maintaining efficiency. ↩

-

Discover the benefits of valves with superior shutoff capabilities, crucial for safety and efficiency in various applications. ↩

-

Understanding fluid control is essential for optimizing processes; this resource will deepen your knowledge in this area. ↩

-

Learn about the structural differences in valves to make informed choices for your industry needs, improving efficiency. ↩