Struggling to choose between ball valves and gate valves for your project? You’re not alone.

Ball valves are fast, reliable shut-off valves ideal for high-cycle, low-pressure drop applications, while gate valves excel in low-frequency isolation for large flow paths.

Choosing the wrong valve could mean pressure drops, clogging, and expensive maintenance downtime. Here’s everything you need to make the right decision.

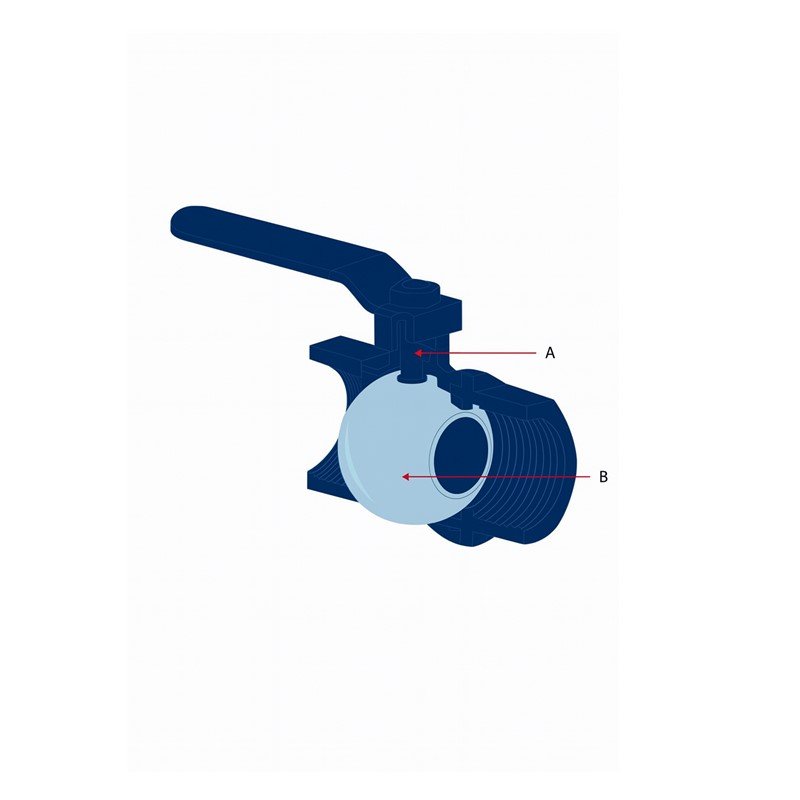

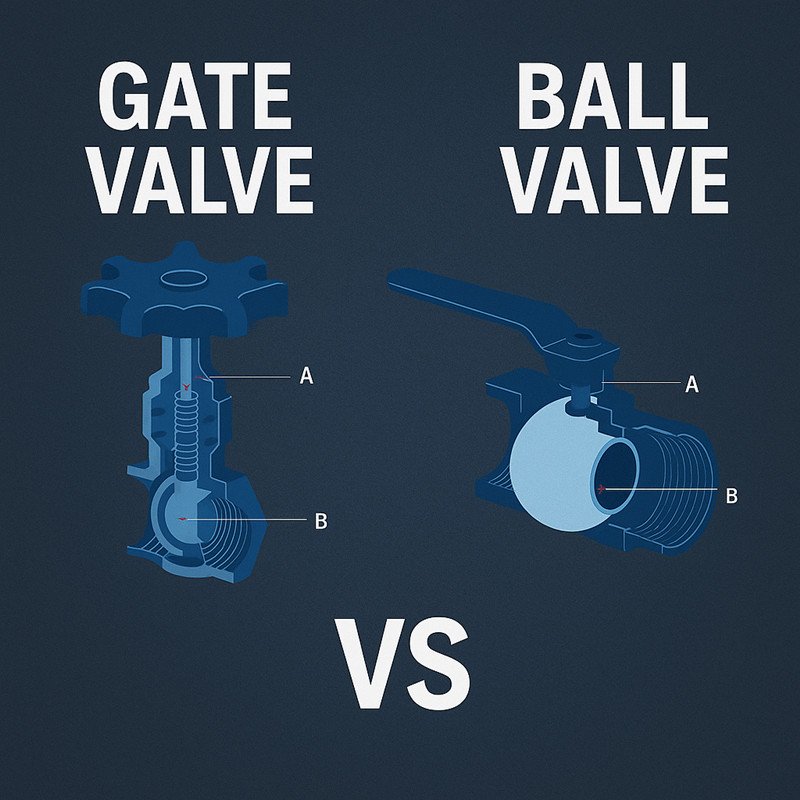

What is a Ball Valve?

Stuck with slow valve operation and fluid hammer issues?

A ball valve uses a perforated, pivoting ball to control flow. It opens quickly with a quarter turn and seals tightly.

Ball valves are one of the most common valves I specify for high-cycle operations where quick shutoff and low leakage are critical.

Types of Ball Valves

- Two-way: Most common, simple on/off operation.

- Three-way: Allows diverting or mixing of flow.

- Four-way or multi-port: Supports complex flow paths like switching circuits.

- Full-port vs Reduced-port:

- Full-port = no flow restriction (ideal for viscous or abrasive media)

- Reduced-port = lower cost, smaller size, but slight pressure loss

Materials and Ratings

| Component | Common Materials | Notes |

|---|---|---|

| Body | SS316, SS304, Brass | Stainless steel for chemical resistance |

| Seats | PTFE, PEEK | PTFE standard, PEEK for high-temp use |

| Seals | Viton, EPDM, NBR | Depends on media compatibility |

Typical pressure ratings: Up to 1000 psi/PN63

Temperature: -20°C to 230°C depending on seat/seal materials

Common Applications

- Chemical plants

- Compressed air systems

- Water treatment skids

- Instrumentation panels

- High-cycle automation processes

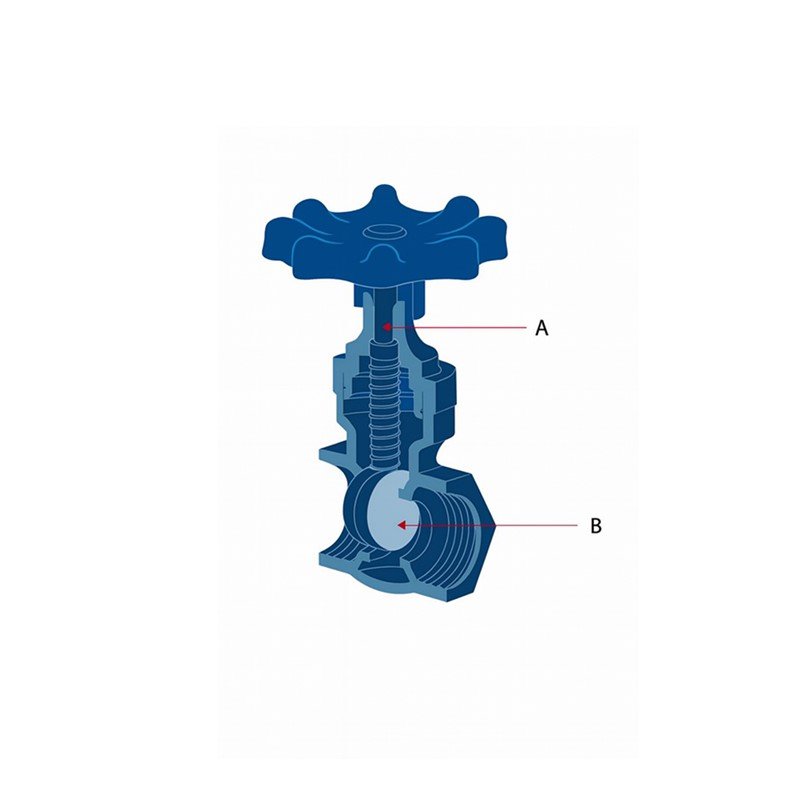

What is a Gate Valve?

Need a low-cost solution for isolating large pipelines?

A gate valve uses a wedge-shaped gate that slides between seats to block flow. It’s best for fully open or closed positions.

Gate valves are great for water and oil pipelines — especially where slow actuation isn’t an issue.

Types of Gate Valves

- Rising stem: Visual position indicator, takes more vertical space

- Non-rising stem: Compact, but requires mechanical position indicator

- Solid wedge: Simple, common, less tolerant to thermal changes

- Flexible wedge: Better sealing, can absorb pipe strain

- Parallel slide: Good for steam systems

Materials and Ratings

| Component | Common Materials | Notes |

|---|---|---|

| Body | Cast iron, SS316, WCB | SS for corrosion, cast iron for budget |

| Wedge | SS316, bronze, ductile iron | Material compatibility is critical |

| Seats | Metal-seated | Rarely soft-seated like ball valves |

Typical pressure ratings: Up to 200 psi /PN16

Temperature: Up to 500°C (depending on seat and body materials)

Common Applications

- Oil and gas pipelines

- Water treatment plants

- HVAC systems

- Steam lines

- Fire protection systems

Key Performance Criteria Comparison

| Criteria | Ball Valve | Gate Valve |

|---|---|---|

| Operating Speed | Quarter-turn, fast | Multi-turn, slow |

| Pressure Drop | Minimal (full port) | Moderate to high |

| Flow Control (Throttling) | Not ideal – can damage seats | Not ideal – can cause vibration/erosion |

| Leakage Potential | Excellent sealing with soft seats | Higher risk due to metal-to-metal seal |

| Maintenance | Low maintenance; seat wear over time | Prone to stem and seat wear |

| Installation Space | Compact (esp. automated) | Large vertical clearance needed |

| Cost (Initial) | Higher | Lower |

| Cost (Lifecycle) | Lower if frequent use | Higher if cycled often |

| Abrasive/Slurry Media | Better with full port and PTFE seats | Poor – can clog and score the gate |

| Multi-Port Capability | Yes (3-way, 4-way) | No |

Application-Specific Guidelines

Water Distribution Pipelines

Use gate valves for main isolation — low cost and reliable.

Use ball valves in branches where fast shutoff is needed.

Oil & Gas Pipelines

Gate valves dominate — especially for large bore, low-cycle isolation.

But for chemical injection skids? I always choose ball valves.

Chemical Processing / Corrosive Environments

Stainless steel or PTFE-lined ball valves with full port design work best.

Gate valves often require exotic alloys — cost skyrockets.

High-Temperature/High-Pressure

Gate valves with metal seats handle better thermal cycling.

Ball valves need special seat material (e.g., PEEK).

Slurries / Viscous Fluids

Go with full-port ball valves — they reduce clogging.

Gate valves may fail due to sediment build-up between seats.

Frequent Operation vs Rare Isolation

High-cycle? Use a ball valve.

Rare use? A gate valve is economical.

Multi-Port/Diverter Applications

Only ball valves offer this — we use them in filtration bypass setups and process loops.

Common Mistakes & Misconceptions

❌ Throttling with ball valves

- Can cause cavitation and seat damage. Use a globe valve instead.

❌ Using gate valves for high-cycle service

- Stem threads and packing degrade quickly — leading to leaks and jamming.

❌ Undersized valves

- Both types have internal flow restrictions depending on port type. Check Cv value.

❌ Material mismatch

- We once saw a gate valve with cast iron body installed in a seawater line — it corroded within 6 months.

❌ Ignoring maintenance access

- Ball valves are easier to remove and replace in tight spaces. Gate valves may require full pipe disassembly.

Valve Selection Checklist

- [ ] Fluid type (corrosive, abrasive, clean?)

- [ ] Required Cv (flow rate)

- [ ] Operating frequency

- [ ] Space constraints

- [ ] Automation needed?

- [ ] Max pressure / temperature

- [ ] Port configuration (straight-through or diverter?)

- [ ] Certification requirements (API, ISO, etc.)

- [ ] Maintenance access?

Conclusion

Choose the right valve not just for the media, but for how often it operates, where it’s installed, and how it affects your system long-term.

A ball valve is perfect for frequent, reliable shutoff. A gate valve is best for infrequent isolation of large flows.

FAQs

Q: Which is better — a gate valve or a ball valve?

A: It depends on the application.

- Use a ball valve for fast shut-off, reliable sealing, frequent operation, or when multi-port flow paths are needed.

- Use a gate valve for large flow rates, cost-sensitive systems, and rarely operated isolation points.

Q: What is the main difference between a gate valve and a ball valve?

A: A gate valve uses a vertical disc (gate) that slides up or down to control flow.

A ball valve uses a rotating ball with a bore; turning 90° opens or closes the valve.

Q: What is a ball valve used for?

A: Ball valves are used as on/off shut-off valves in systems requiring tight sealing, low pressure drop, and high durability — such as water, air, and chemical pipelines.

Q: When should I use a gate valve?

A: Gate valves are ideal for isolation in large-diameter lines, especially when:

- Flow needs to be fully open or fully closed

- The system handles slurries or dirty fluids

- Cost or pressure drop is a concern

- Operation is infrequent

Further Resources

Beyond Fluid — Stainless Steel ball valves and gate valves Manufacturer in China

www.beyondfluid.com