Top China DIN 2353 Cutting-Ring Tube Fittings Manufacturer

For over 15 years, we have been a trusted supplier of DIN tube fittings to wholesalers, distributors, and large contractors worldwide. Our mission is to solve your supply challenges and help expand your market share. Partner with Beyond Fluid to achieve lasting business success.

Leading Wholesale Supplier of DIN 2353 Tube Fittings in China

Beyond Fluid manufactures stainless steel DIN 2353 tube fittings that meet DIN 2353 and ISO 8434-1 standards, and are compatible with major brands like Parker Ermeto.

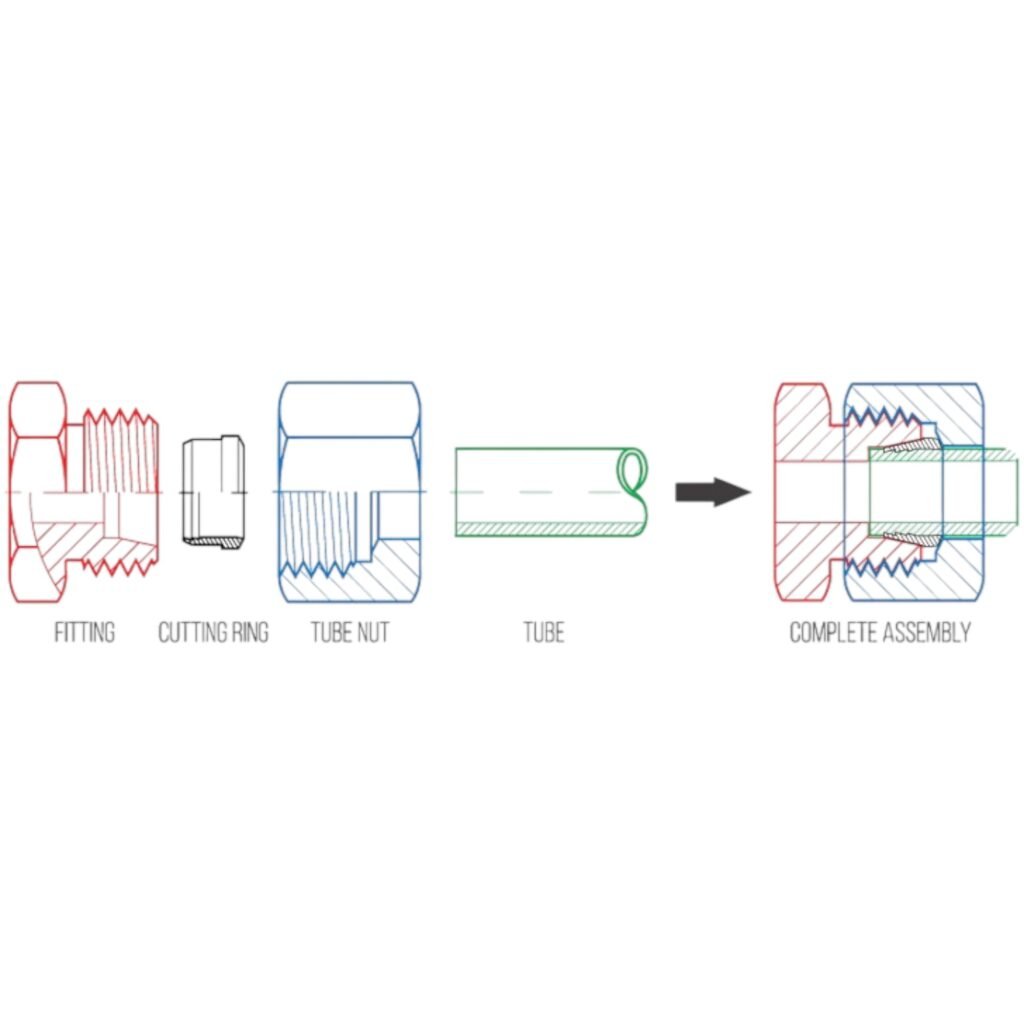

Each fitting includes a body, cutting ring, and nut. The cutting ring’s edges bite into the tube surface during assembly, ensuring a secure, leak-free seal under high pressure and vibration.

Available in metric O.D. sizes from 4mm to 42mm, using high-grade materials such as AISI 304, 316L, and 316Ti, Beyond Fluid is the ideal partner for wholesalers, distributors, and large contractors.

Specification:

- Standard: DIN 2353 & ISO 8434-1

- Size: 4mm-38mm

- Material: SS304, SS316L, SS316Ti, Alloy etc

- Series: LL(very light), L(light), S(heavy)

- Cutting-Ring: Hardening Heat treatment

- Shape: Straight, 90° Elbow, Tee, Cross, plug, cap

- End Connection: BSP, BSPP, NPT, Metric, Weld

- Seal Material: NBR, FKM Viton

- Working Pressure: Up to 10,000 PSI

Hot-Selling Products

Type: single ferrule | Series: LL, L, S | Size: 4mm to 38mm | Material: SS304, SS316L

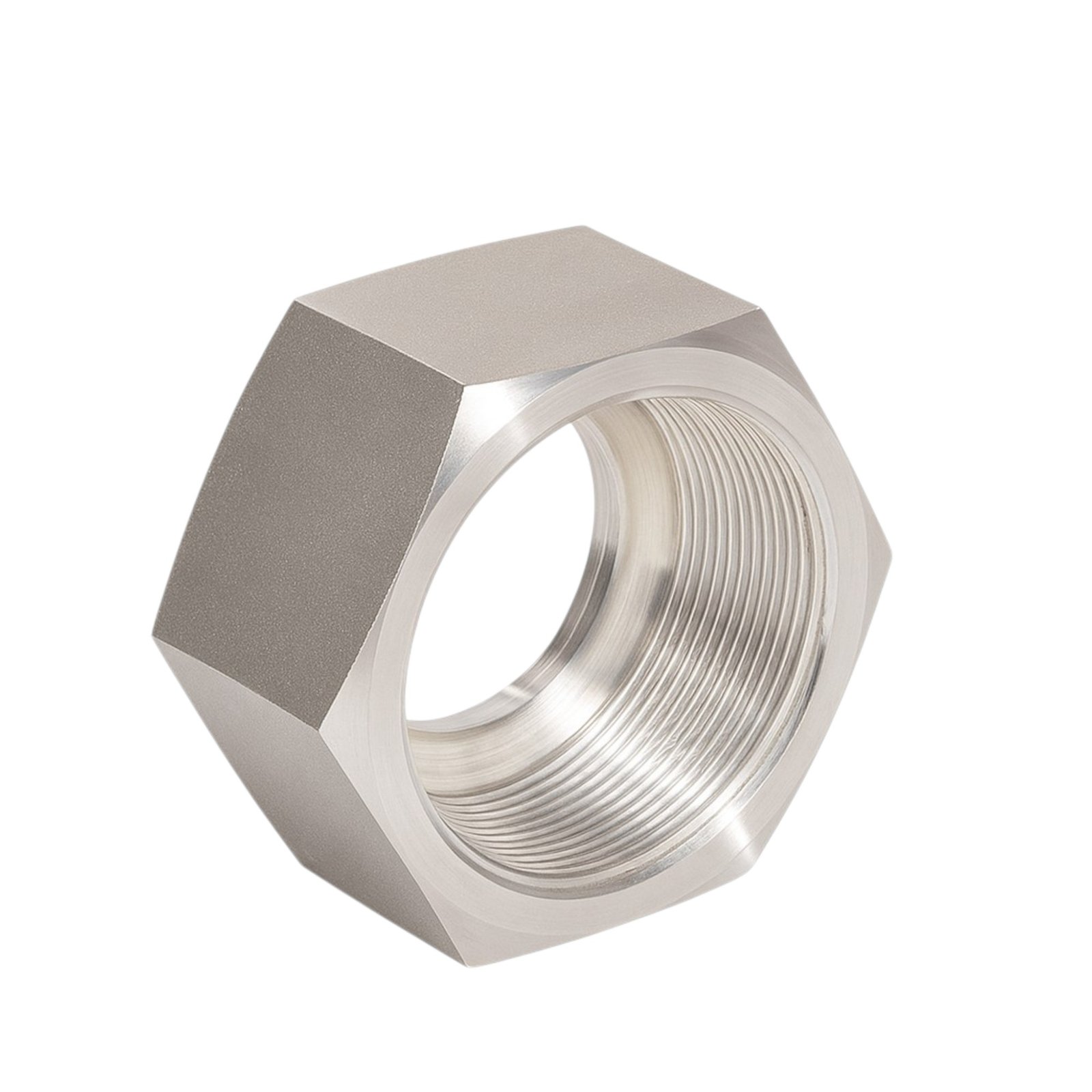

Type: nut | Series: LL, L, S | Size: 4mm to 38mm | Material: SS304, SS316L

Type: weld nipple | Series: LL, L, S | Size: 4mm to 38mm | Material: SS304, SS316L

Type: din plug | Series: LL, L, S | Size: 4mm to 38mm | Material: SS304, SS316L

Type: straight tube union | Series: LL, L, S | Size: 4mm to 38mm | Material: SS304, SS316L

Type: male thread connector | Series: LL, L, S | Size: 4mm to 38mm | Material: SS304, SS316L

Type: ED seal male connector | Series: LL, L, S | Size: 4mm to 38mm | Material: SS304, SS316L

Type: straight bulkhead union | Series: LL, L, S | Size: 4mm to 38mm | Material: SS304, SS316L

Type: 90° eblow | Series: LL, L, S | Size: 4mm to 38mm | Material: SS304, SS316L

Type: tee union | Series: LL, L, S | Size: 4mm to 38mm | Material: SS304, SS316L

Type: cross union | Series: LL, L, S | Size: 4mm to 38mm | Material: SS304, SS316L

Type: banjo fitting | Series: LL, L, S | Size: 4mm to 38mm | Material: SS304, SS316L

Competitor Cross Reference For Typical DIN Fittings

Beyond Fluid’s DIN 2353 tube fittings are equivalent to many brands. Such as Parker Ermeto, Adaptall, and Exmar. Please see below for reference:

| Beyond Fluid | Parker Ermeto | Adaptall | Exmar |

|---|---|---|---|

| DPR-L/S Series | DPR-L/S Series | 5202 Series | SR-L/S Series |

| M Nut Series | M Nut Series | 5201-L/S Series | UEM-L/S Series |

| G Union Series | G Union Series | 5000L/S Series | XGV-L/S Series |

| GE-R-ED Series | GE-R-ED Series | 5002L/S Series | XGV-LR-WD Series |

| GZ Swivel union Series | GZ Swivel union Series | 5300L/S Series | VKO-L/S Series |

| EW Swivel Nut Elbow Series | EW Swivel Nut Elbow Series | 5360L/S Series | XEWKO-L/S M Series |

| W Union Elbow Series | W Union Elbow Series | 5055L/S Series | XWV-L/S Series |

| T Union Tee Series | T Union Tee Series | 5080L/S Series | XTV-L/S Series |

| SV Bulkhead Union Series | SV Bulkhead Union Series | 5040L/S Series | XGSV-L/S KM Series |

| WSV Bulkhead Elbow Series | WSV Bulkhead Elbow Series | 5042L/S Series | XWSV-L/S KM Series |

| EGE-R-ED Swivel Connector Series | EGE-R-ED Swivel Connector Series | 5302L/S Series | EGKO-LM WD/SM WD Series |

| RED Tube and Reducer Series | RED Tube and Reducer Series | 5360L/S Series | XGKO-L/S M Series |

| GE-NPT Male Stud Connector Series | GE-NPT Male Stud Connector Series | 5007L/S Series | XGEV-L/S NPT Series |

| ROV Blanking Plug For Tube Ends Series | ROV Blanking Plug For Tube Ends Series | 5203L/S Series | XVSA-…L/S Series |

Thread Chart and Sizes For DIN 2353 Connectors

| PRESSURE SERIES | TUBE O.D | METRIC THREAD CALLOUT | WORKING PRESSURE (BAR)* |

|---|---|---|---|

| LL | 4 mm | 8 mm x 1.0 | 100 |

| LL | 6 mm | 10 mm x 1.0 | 100 |

| LL | 8 mm | 12 mm x 1.0 | 100 |

| LL | 10 mm | 14 mm x 1.0 | 100 |

| LL | 12 mm | 16 mm x 1.0 | 100 |

| PRESSURE SERIES | TUBE O.D | METRIC THREAD CALLOUT | WORKING PRESSURE (BAR)* |

|---|---|---|---|

| L | 6 mm | 12 mm x 1.5 | 315 |

| L | 8 mm | 14 mm x 1.5 | 315 |

| L | 10 mm | 16 mm x 1.5 | 315 |

| L | 12 mm | 18 mm x 1.5 | 315 |

| L | 15 mm | 22 mm x 1.5 | 315 |

| L | 18 mm | 26 mm x 1.5 | 315 |

| L | 22 mm | 30 mm x 2.0 | 160 |

| L | 28 mm | 36 mm x 2.0 | 160 |

| L | 35 mm | 45 mm x 2.0 | 160 |

| L | 42 mm | 52 mm x 2.0 | 160 |

| PRESSURE SERIES | TUBE O.D | METRIC THREAD CALLOUT | WORKING PRESSURE (BAR)* |

|---|---|---|---|

| S | 6 mm | 14 mm x 1.5 | 630 |

| S | 8 mm | 16 mm x 1.5 | 630 |

| S | 10 mm | 18 mm x 1.5 | 630 |

| S | 12 mm | 20 mm x 1.5 | 630 |

| S | 14 mm | 22 mm x 1.5 | 630 |

| S | 16 mm | 24 mm x 1.5 | 400 |

| S | 20 mm | 30 mm x 2.0 | 400 |

| S | 25 mm | 36 mm x 2.0 | 400 |

| S | 30 mm | 42 mm x 2.0 | 400 |

| S | 38 mm | 52 mm x 2.0 | 315 |

Features of DIN 2353 Fittings

Beyond Fluid’s DIN 2353 tube fittings provide high-pressure, leak-free performance for hydraulic and pneumatic systems.

Each fitting includes a body, nut, and cutting ring. The cutting ring bites into the tube during assembly, ensuring a strong, metal-to-metal seal that resists vibration and pressure cycling.

Available in three series:

- LL – Very Light (up to ~100 bar)

- L – Light (up to ~500 bar)

- S – Heavy (up to ~800 bar)