Stainless Steel Flanged Ball Valves Manufacturer in China

Flanged ball valves are quarter-turn shut-off valves with flanged ends, designed for secure and standardized connection in medium to high pressure piping systems.

Beyond Fluid is a professional stainless steel flanged ball valves manufacturer in China, supplying SS304 & SS316 flanged ball valves for industrial projects, wholesalers, distributors, and OEMs.

Flange Standard: ANSI / DIN /JIS | Pressure Class: Class 150 / 300 | Size Range: DN15 – DN300

What is a Flanged Ball Valve?

A flanged ball valve is a quarter-turn shut-off valve equipped with flanged ends, allowing it to be bolted directly to pipeline flanges for a secure and standardized connection.

By rotating the handle 90 degrees, the valve opens or closes flow through a precision-machined ball. Flanged ball valves are commonly used in medium to high pressure systems where strength, sealing reliability, and alignment accuracy are critical.

Compared with threaded ball valves, flanged ball valves are better suited for larger pipe sizes and industrial applications such as oil & gas, chemical processing, power plants, and water treatment systems.

Feature:

- Technical: Investment Casting

- Casting Approved: AD2000-W0

- Standard: JIS, DIN, ANSI

- Stem: blow-out proof stem

- Design: 1 PC, 2 PC, 3 PC

- Material: SS304/CF8, SS316/CF8M, WCB

- Seal Material: PTFE, R-PTFE

- Connection: flange

- Inspection: API598, JIS B2003, EN12266

- Media: water, gas, oil

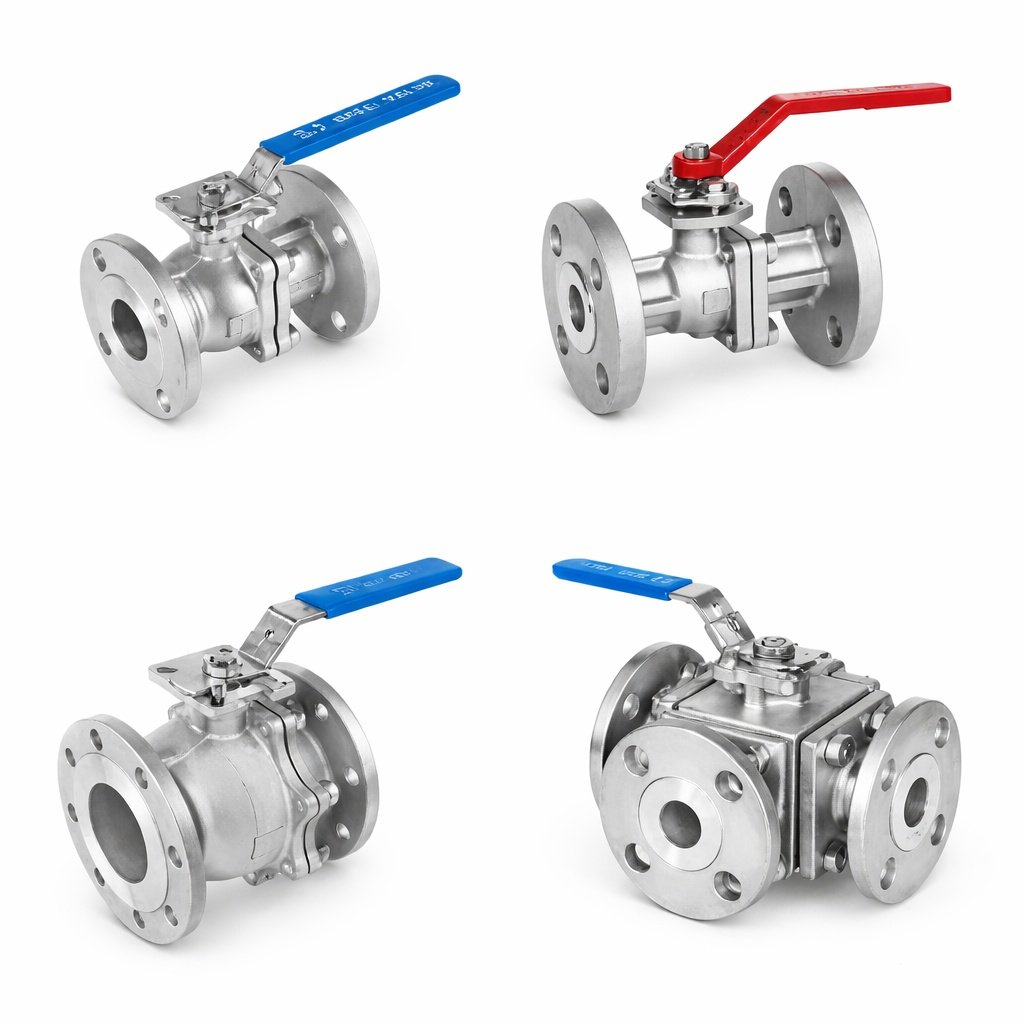

Types of Stainless Steel Flanged Ball Valves

A 1 PC flanged ball valve features a single solid body with flanged ends, controlling fluid flow by rotating the internal ball 90 degrees.

A 2 PC flanged ball valve features two connected body pieces with flanged ends, allowing easy installation into a piping system.

A 3 PC flanged ball valve allows easy maintenance by removing the central body without disrupting the pipeline, ensuring secure connections.

A 3-way flanged ball valve controls fluid flow in multiple directions, using a T-shaped or L-shaped bore to divert or mix.

A flanged gate valve controls fluid flow by raising or lowering a flat gate within the valve body.

A flanged globe valve controls fluid flow with a movable disk on a stationary ring seat in a spherical body.

Technical Specifications of Flanged Ball Valves

Below are the standard technical specifications of our stainless steel flanged ball valves. Custom materials, pressure classes, and flange standards are available upon request.

| Parameter | Specification |

|---|---|

| Valve Type | Stainless Steel Flanged Ball Valve |

| Body Material | SS304 (CF8), SS316 (CF8M) |

| Design Type | 2-Piece, 3-Piece, Floating Ball |

| Port Type | Full Port / Reduced Port |

| Size Range | DN15 – DN300 |

| Pressure Rating | Class 150 / Class 300 |

| Flange Standard | ANSI / DIN / JIS |

| Face-to-Face | ASME B16.10 / EN 558 |

| Seat Material | PTFE, R-PTFE |

| Stem Sealing | PTFE Packing |

| Operation | Manual Lever Handle (Gear Optional) |

| Applicable Media | Water, Oil, Gas, Steam |

| Working Temperature | -20°C to 180°C |

| Testing | 100% Pressure & Leakage Tested |

| Manufacturing Process | Investment Casting & CNC Machining |

| Quality Standard | ISO 9001 |

ANSI vs DIN Flange Standards – How to Choose?

Selecting the correct flange standard is essential for proper installation and sealing. ANSI and DIN flange standards are not interchangeable and are used in different regions and piping systems.

| Item | ANSI Flanged Ball Valves | DIN Flanged Ball Valves |

|---|---|---|

| Standard System | American Standard (ASME / ANSI) | European Standard (DIN / EN) |

| Common Standards | ASME B16.5 | EN 1092-1 |

| Pressure Rating | Class 150, Class 300 | PN16, PN25, PN40 |

| Nominal Size | NPS (inch-based) | DN (metric-based) |

| Bolt Pattern | ASME bolt circle dimensions | DIN / EN bolt circle dimensions |

| Typical Markets | USA, Middle East, Oil & Gas projects | Europe, UK, Water & industrial systems |

| Compatibility | ❌ Not compatible with DIN | ❌ Not compatible with ANSI |

How to choose: Select ANSI flanged ball valves for projects following ASME standards, commonly used in the USA and Middle East. Choose DIN flanged ball valves for European and metric-based piping systems. Always confirm flange standard, pressure rating, and bolt dimensions before ordering.

How to Choose the Right Flanged Ball Valve?

Selecting the right flanged ball valve depends on pressure class, valve structure, ball design, and material. The guidelines below help ensure safe operation and long-term reliability.

Class 150 vs Class 300

Class 150 flanged ball valves are suitable for low to medium pressure applications and are widely used in water systems, general industry, and standard process lines.

Class 300 flanged ball valves are designed for higher pressure and temperature conditions, commonly used in oil & gas, chemical processing, and critical industrial pipelines.

Recommendation: Choose Class 150 for standard pressure systems; select Class 300 for higher pressure or more demanding operating conditions.

1-Piece vs 2-Piece vs 3-Piece Flanged Ball Valves

1-piece flanged ball valves feature a compact, one-body design and are mainly used for simple applications where maintenance is not required.

2-piece flanged ball valves offer a balance between strength and cost, making them the most common choice for industrial on/off flow control.

3-piece flanged ball valves allow inline maintenance without removing the valve from the pipeline, ideal for systems requiring frequent inspection or cleaning.

Recommendation: Choose 2-piece for most applications; use 3-piece when maintenance access is important.

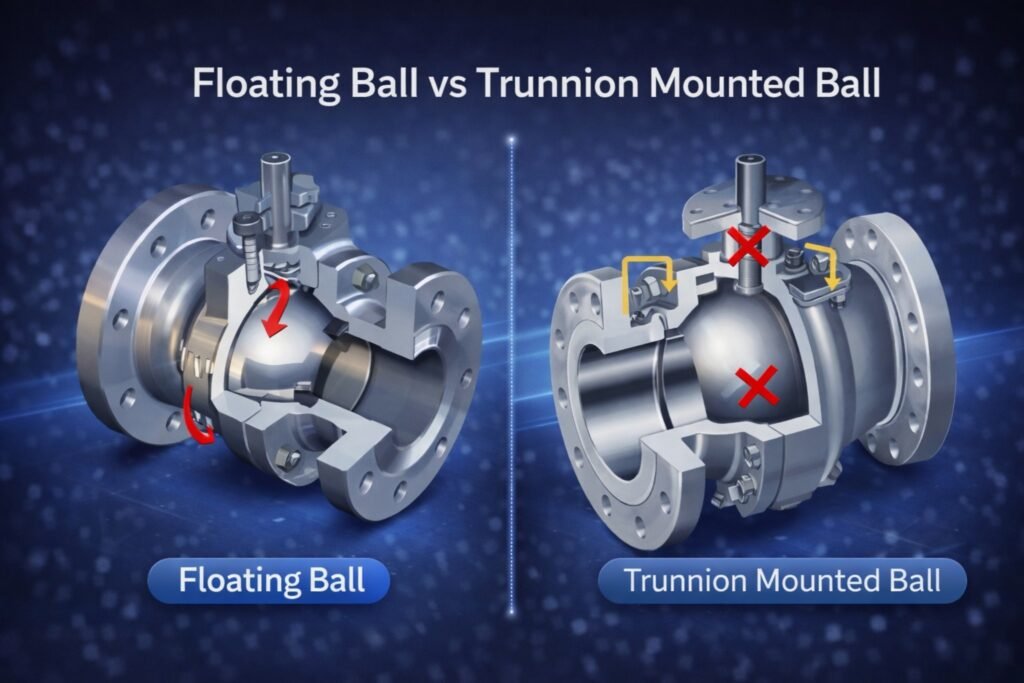

Floating Ball vs Trunnion Mounted Ball

Floating ball valves rely on line pressure to seat the ball against the downstream seat. They are suitable for small to medium sizes and moderate pressure ratings.

Trunnion mounted ball valves support the ball with upper and lower trunnions, reducing operating torque and providing better stability for large sizes and high-pressure applications.

Recommendation: Choose floating ball for smaller sizes and lower pressure; select trunnion mounted designs for large diameter or high-pressure systems.

SS304 vs SS316 Stainless Steel

SS304 flanged ball valves provide good corrosion resistance for most general industrial applications, including water, air, and mild chemical environments.

SS316 flanged ball valves offer enhanced resistance to corrosion, especially in chloride-rich or aggressive media, making them suitable for chemical plants and Middle East outdoor installations.

Recommendation: Use SS316 for corrosive or harsh environments; select SS304 for standard service conditions.

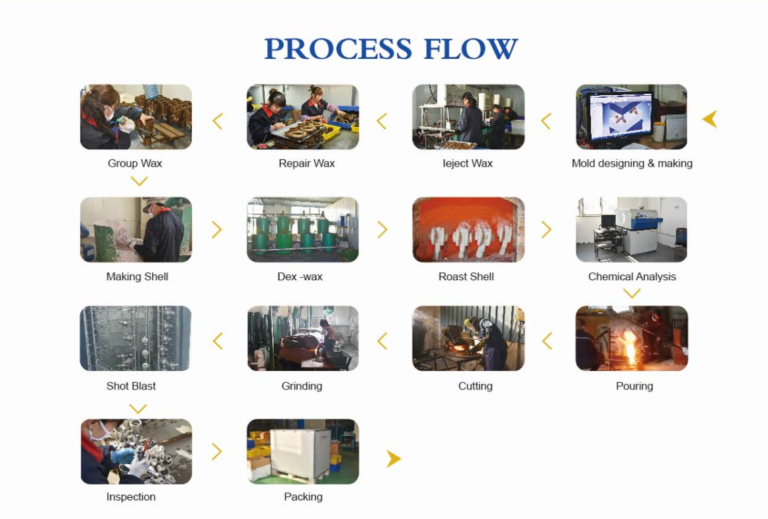

Manufacturing Process For Flanged Ball Valves At Beyond Fluid

At Beyond Fluid, we take great care in manufacturing our flanged valves. From the first mold to the final packaging, every step is closely monitored to ensure strict quality control. This meticulous process guarantees that our products meet the highest standards of excellence.

Technical Support

At Beyond Fluid, we pride ourselves on our comprehensive expertise in engineering and designing flanged ball valves. From the initial concept to the final product, our team is equipped to transform your ideas into tangible, high-quality fluid and control solutions. Our commitment to innovation ensures that we deliver not just products, but value-driven solutions tailored to your needs.

- Tailored Solutions

- Techical Support

- Free Drawings Service

Who We Are

Beyond Fluid, Your Reliable Flanged Valves Manufacturer

Beyond Fluid has over 15 years of experience supplying stainless steel flanged valves to wholesalers, distributors, and large contractors. We offer reliable quality, excellent service, on-time delivery, and competitive prices. Our commitment to advanced technology, precision engineering, and strict quality standards ensures we meet the diverse needs of customers worldwide.

We take pride in producing high-quality stainless steel ball valves and fittings. Our comprehensive range of products is designed for optimal performance and durability, with both standard and customized solutions. Serving industries from oil and gas to water treatment, we aim to be your long-term trusted partner to expand your market presence.

Why Choose Us

Reliability. Consistency. Integrity

When you choose Beyond Fluid, you ensure precision and reliability, backed by our strict Quality Assurance Program.

Beyond Fluid ensures reliability with a 99.99% on-time delivery rate and quick response to urgent orders through stocked materials.

Our robust manufacturing and supply chain enable us to offer competitive prices, helping clients expand their market reach.

Our expert engineers offer design, CAD, and technical support, while our trained sales team ensures fast, efficient 24-hour responses.

Testimonials

What Our Clients Say

A Large Wholesaler From USA

“We’re literally satisfied with Beyond Fluid’ always on-time delivery and exceptional handling of requests. Their commitment to timely service is evident and consistently reliable. Their swift response and guaranteed on-time delivery make them my preferred choice.”

A Brand Manufacturer From Germany

“We can always count on Beyond Fluid’s quality. During a 2018 visit, their advanced facilities and stringent quality controls made a lasting impression on us. Their timely responses to requests for drawings or technical support further solidify my trust. We really love to place our orders to those suppliers like Beyond Fluid.”

FAQ

Frequently Asked Questions.

Here are a few real most popluar questions from our clients.

Beyond Fluid manufactures and supplies a wide range of valves, including 1-piece flanged ball valves, 2-piece flanged ball valves, and 3-piece flanged ball valves, 3-way flanged ball valves, flanged gate valves, and flanged globe valves. Additionally, we have the capability to design and produce custom valves based on customer drawings or samples.

Beyond Fluid manufactures and supplies flanged valves in stainless steel(SS304, SS316, and SS316L), and WCB material.

With over 15 years of manufacturing experience and a commitment to 100% testing before shipment, Beyond Fluid has a strong track record of successfully supplying flanged valves to wholesalers, distributors, and large contractors worldwide.

Sure, we are able to provide material certificates with full traceability back to the steel mill for each shipment.

Besides, we can also mark the material grade and heat number on the fittings and valves.

Yes, we accept OEM orders. In fact, we have successfully helped several brand manufacturers significantly reduce their production costs while enabling them to expand their market share.