Controlling the flow of fluids in a system can be tricky, especially when precise regulation is needed. That’s where control valves step in. But, how exactly do they function within the instrumentation industry? Let’s dive in.

Control valves are crucial in the instrumentation industry as they regulate the flow, pressure, and temperature of liquids or gases in a system. They ensure optimal conditions for system performance.

Control valves serve a significant role in systems requiring precise fluid or gas flow regulation. Now, let’s explore what these valves are and how they work in more detail.

What is a control valve in instrumentation?

Control valves are mechanical devices used to control the flow of fluids in a process system. They re

Control valves serve a significant role in systems requiring precise fluid or gas flow regulation1. Now, let’s explore what these valves are and how they work in more detail.

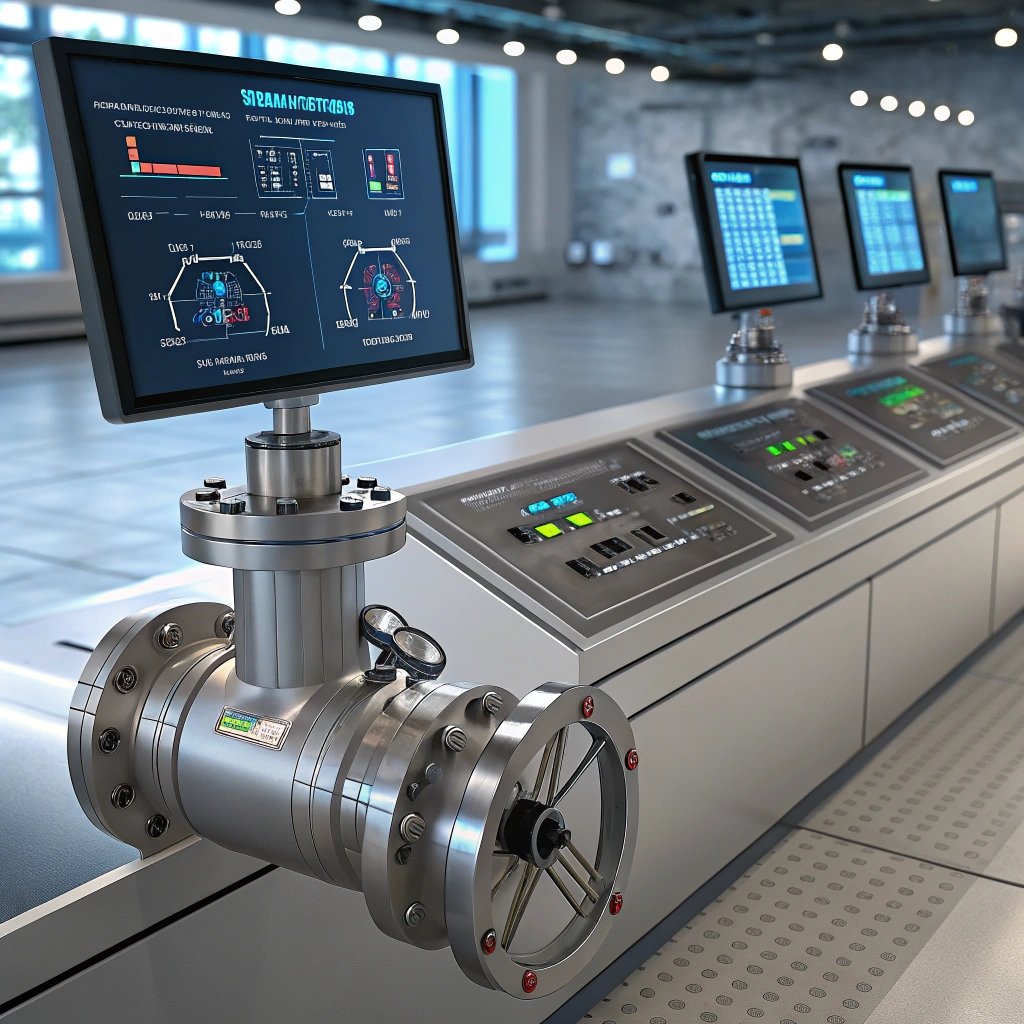

Control valves in instrumentation systems ensure processes run smoothly, maintaining the correct parameters for the system. These valves respond to signals from controllers to adjust flow rates or other variables.

Function of Control Valves

Control valves are designed to work with other components in a process system. In instrumentation, the control valve adjusts its position to maintain specific system conditions, such as flow rate or pressure. The flow rate is typically monitored by a controller that sends signals to the valve. Based on these signals, the valve opens or closes to maintain optimal conditions.

Control valves are essential in automated systems2 because they help maintain constant system variables. They allow for a high level of accuracy in controlling the amount of fluid entering or leaving a process. The main types of control valves used in instrumentation systems include ball, globe, and butterfly valves.

| Type of Control Valve | Application | Key Features |

|---|---|---|

| Ball Valve | Used for on/off control and high-flow applications. | Quick opening, low pressure drop. |

| Globe Valve | Used for throttling applications. | Good for precise flow control. |

| Butterfly Valve | Used in low-pressure systems. | Lightweight, cost-effective. |

How do the valves work on an instrument?

Control valves operate by receiving signals from controllers3 or other devices within the system. These signals are often electrical or pneumatic, depending on the control system being used. The valve then adjusts its position accordingly to maintain the desired process conditions.

Control valves respond to input from the system’s controller. The signal determines whether the valve should open more, close, or maintain its current position.

Components of Control Valves

A control valve system is made up of various components that work together:

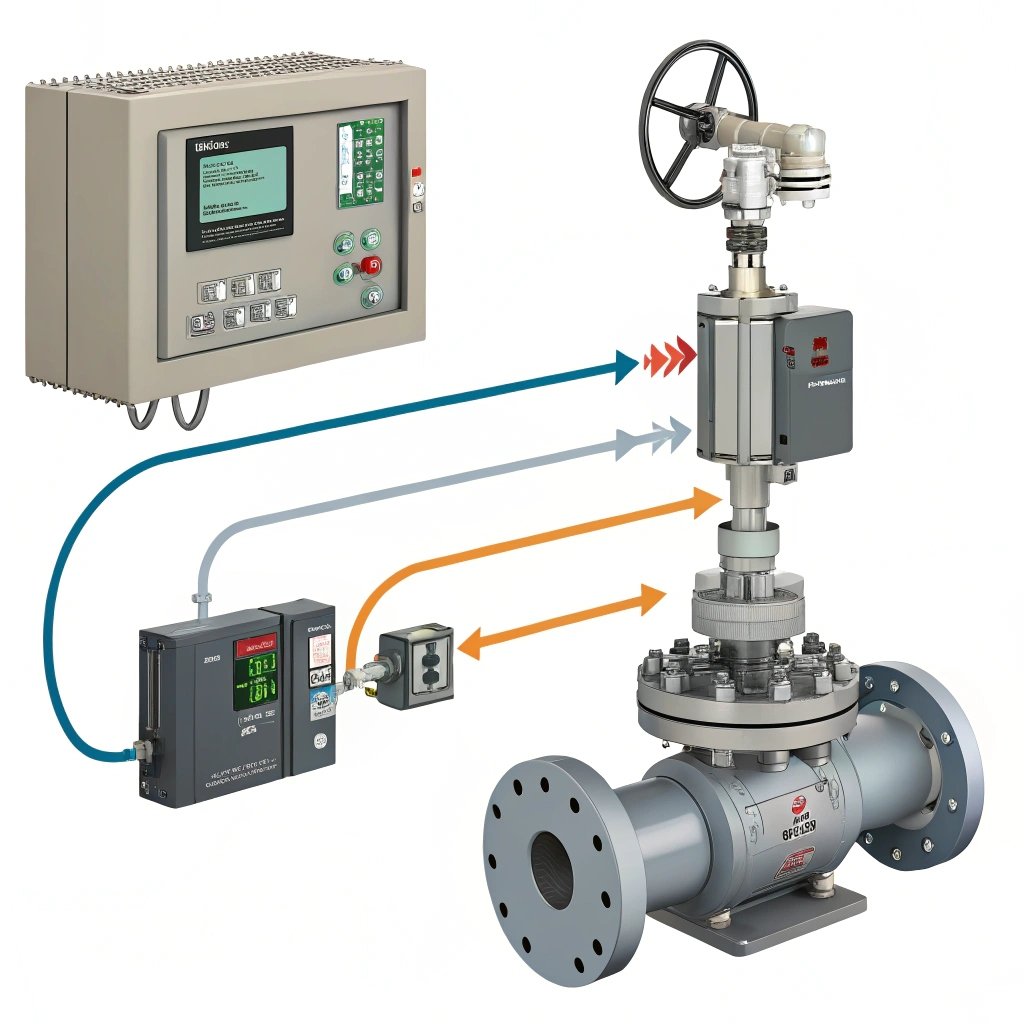

- Actuator: The actuator is responsible for moving the valve. It can be either pneumatic, hydraulic, or electric.

- Positioner: This component ensures the valve reaches the correct position according to the controller’s signal.

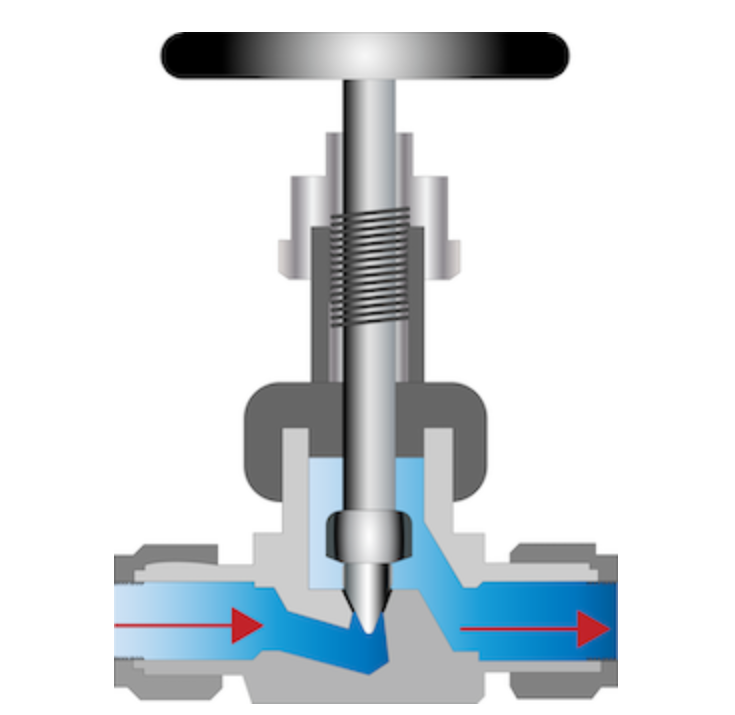

- Valve Body: The valve body holds the valve’s internals, such as the plug or ball, and directs the flow of the fluid.

- Valve Trim: The valve trim is the internal assembly that controls the flow, including the plug or ball and seat.

These components work together to control the flow of fluid or gas through the valve. When the controller sends a signal, the actuator moves, adjusting the valve position. The positioner ensures the valve is in the correct position to maintain the system’s desired flow rate or pressure.

Control Valve vs. Isolation Valve

It’s important to distinguish between control valves and isolation valves as they serve different purposes in a system.

| Valve Type | Function | Application |

|---|---|---|

| Control Valve | Modulates flow to maintain system parameters. | Used in automated process control systems for fluid or gas flow regulation. |

| Isolation Valve | Stops flow entirely to isolate sections of the system. | Used for maintenance, repair, or shutdowns in the system. |

How does a control valve work?

A control valve works by regulating the flow of fluids or gases within a system. The key factor in a control valve’s operation is its ability to respond to input signals from the control system.

Control valves act as the “hands” of a process control system, responding to signals and adjusting the flow to keep the system running within the desired parameters.

The Process Flow of a Control Valve

- Input Signal: The control system sends an input signal to the valve. This signal can be electrical or pneumatic, depending on the system.

- Actuation: The actuator receives the signal and adjusts the valve’s position. It may either open or close the valve, depending on the signal.

- Flow Adjustment: As the valve moves, it changes the flow rate, pressure, or temperature of the fluid passing through the system.

- Feedback: The valve system continuously adjusts to maintain the desired process condition. Feedback is sent to the controller, which makes further adjustments as necessary.

Control valves are used in applications where precise control of fluid or gas flow is needed. They are common in industries like chemical processing, oil and gas, and water treatment.

Control Valve vs. Pressure Relief Valve

Another important comparison is between control valves and pressure relief valves. Both are critical to maintaining safe and efficient system operations but serve different roles.

| Valve Type | Function | Application |

|---|---|---|

| Control Valve | Regulates flow, pressure, and temperature according to system needs. | Used in active process control to maintain system stability. |

| Pressure Relief Valve | Opens to release pressure when it exceeds a predetermined limit. | Protects the system from over-pressurization, ensuring safety. |

What is the function of instrumentation valve?

Instrumentation valves are an integral part of control systems, designed to isolate, regulate, or protect system components. These valves control the flow and pressure within the system, ensuring the correct parameters for smooth operation.

Instrumentation valves ensure the safety, reliability, and efficiency of process systems4. They allow for precise control over variables like pressure, temperature, and flow rates.

Types of Instrumentation Valves

Instrumentation valves can perform different functions depending on the system’s needs. Here are some types commonly used:

- Isolation Valves: These valves are used to isolate a section of the system for maintenance or repair.

- Check Valves: Check valves ensure that fluid only flows in one direction, preventing backflow.

- Relief Valves: Relief valves protect the system from excessive pressure by releasing fluid if pressure exceeds a set limit.

These valves are often used in systems requiring high precision, such as in control loops for pressure or temperature regulation. Their function ensures that each part of the system operates at its optimal performance, maintaining the desired conditions.

Top Suppliers of Control Valves

If you’re looking for reliable suppliers of control valves in the instrumentation industry, here are some of the top players globally:

-

Emerson Electric Co.

Emerson is a global leader in automation technology, offering a wide range of control valves and instrumentation solutions. Their products are known for reliability, precision, and innovation, catering to various industries, including oil and gas, chemicals, and water treatment. -

Beyond Fluid

Beyond Fluid specializes in manufacturing stainless steel valves and fittings, including control valves. With over 15 years of experience, they provide high-quality, cost-effective solutions tailored to the needs of international distributors and contractors. Based in China, Beyond Fluid offers fast shipping worldwide, making them a top choice for those seeking reliable and competitively priced valves. -

Honeywell

Honeywell is a global technology leader offering advanced control valve systems for industrial applications. Their products are known for their durability and performance, especially in complex process systems where precision control is critical. Honeywell serves various sectors, including petrochemical, pharmaceutical, and HVAC industries. -

Fisher Controls (a division of Emerson)

Fisher, a division of Emerson, is well-regarded for its control valve solutions. Their products are designed for use in critical industrial processes, providing excellent accuracy, long service life, and ease of maintenance. Fisher control valves are widely used in industries like chemical processing, power generation, and refining. -

Schneider Electric

Schneider Electric is renowned for its energy-efficient control valve solutions, which are integrated with its broader automation and control systems. Known for providing comprehensive solutions for the industrial and energy sectors, Schneider Electric’s products are built for high performance and sustainability.

These suppliers are trusted by industries worldwide for providing durable, high-performance control valves that meet a wide variety of process control needs.

These suppliers offer robust products that are known for their durability and performance across various industrial applications. Whether you’re looking for valves for automation systems or industrial control systems, these suppliers can meet your needs.

Conclusion

Control valves are essential in the instrumentation industry, offering precise control over fluid and gas flow. They ensure that systems run smoothly and efficiently by responding to input signals and maintaining desired process conditions. Whether you are sourcing valves for large-scale applications or specialized systems, companies like Beyond Fluid provide high-quality options that deliver reliability and performance.

-

Exploring this topic will provide insights into the importance of flow regulation in various industrial applications.

gulate the rate at which a fluid flows through a pipe, as well as the pressure and temperature of the fluid, by varying the size of the opening through which the fluid passes. ↩ -

Discovering the role of control valves in automation can lead to better system design and performance. ↩

-

Learn about the different signals that control valves respond to, enhancing your knowledge of automation systems. ↩

-

Explore the significance of process systems to understand their impact on industrial operations and efficiency. This link offers valuable insights. ↩