A ball valve is a simple yet highly effective device used to control the flow of fluids and gases1 in various systems. Understanding how to check whether a ball valve is open or closed is crucial for both efficient operations and safety. In this article, we’ll explore the different aspects of ball valves—from their working principles to practical tips on identifying their positions2.

Ball valves are crucial components in many industries, and knowing how to properly operate them ensures smooth and safe flow control. In this article, we’ll cover the basics of ball valves, how they work, and how you can identify whether one is open or closed.

How Ball Valves Work?

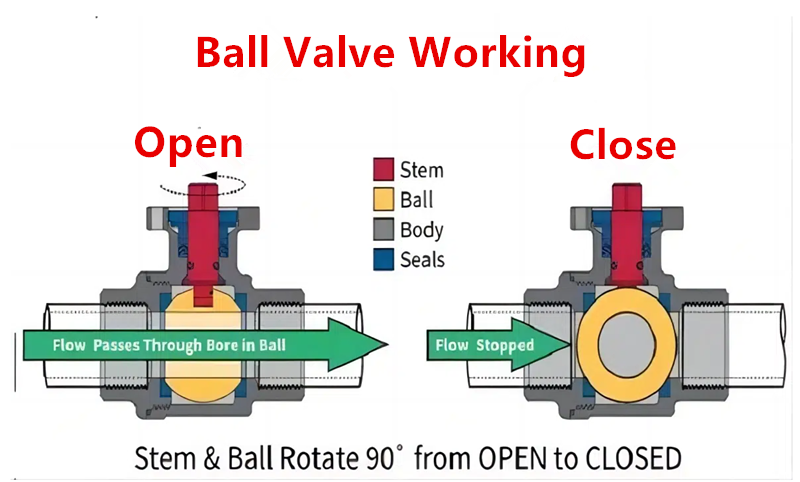

Ball valves are used widely in fluid control systems due to their simplicity, reliability, and effectiveness. The basic structure of a ball valve includes a spherical ball with a hole through its center, which controls the flow of fluid. When the valve handle is turned, the ball rotates inside the valve body, aligning or misaligning the hole with the flow path.

There are two common types of ball valves: full-port and standard-port. The difference lies in the ball’s size and the flow area.

- Full-port ball valve: The hole in the ball is the same size as the pipe, allowing for minimal resistance to flow.

- Standard-port ball valve: The hole is smaller than the pipe diameter, which can create slightly more resistance.

The working principle is simple—when the hole in the ball aligns with the pipe, the valve is open, and when it’s turned 90 degrees so the hole is perpendicular to the pipe, the valve is closed.

How to Tell If a Ball Valve Is Open or Closed

One of the easiest ways to tell if a ball valve is open or closed is by observing the handle orientation. Most ball valves have a handle that can be positioned in one of two ways to indicate whether the valve is open or closed.

Step-by-Step Guide to Checking the Valve’s Position

-

Visual Cues:

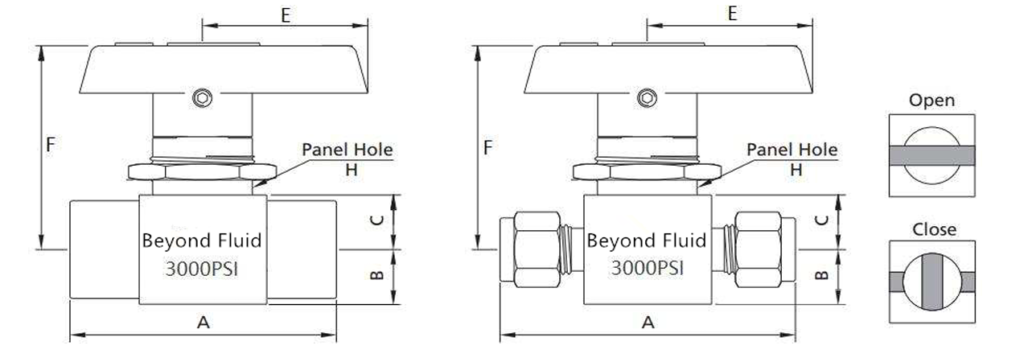

- Handle Position: For most valves, the handle will be perpendicular (90 degrees) to the pipe when the valve is closed and parallel with the pipe when the valve is open.

- Flow Direction Indicators: Some valves have flow arrows printed on their body. These indicate the direction in which the fluid flows when the valve is open.

-

Ball Valve Indicators:

- Many valves have an indicator window on the valve body, which shows whether the ball inside is aligned with the pipe (open) or perpendicular to it (closed).

-

Remote Monitoring:

- For large or hard-to-reach systems, there are remote monitoring systems or valve position sensors available. These systems use digital indicators or actuators that allow you to check the valve status from a distance.

-

Testing the Valve:

- If visual inspection isn’t possible or reliable, you can also test the valve by briefly operating the system. If the flow stops, the valve is likely closed. If the flow continues, the valve is open.

Safety and Performance Tips

Operating ball valves involves more than just turning a handle. To ensure long-lasting performance and avoid accidents, it’s important to follow some basic safety tips:

-

Avoid Over-Torquing: Turning the handle too forcefully can damage the valve or cause it to fail prematurely. Always apply pressure slowly and carefully to avoid over-torquing.

-

Handle with Care: Ball valves are durable, but mishandling can cause issues. Avoid using the handle to leverage or force open the valve.

-

Check for Leaks: After operating a ball valve, always check for leaks. Any signs of leakage may indicate improper seating or a worn-out seal.

-

Temperature Considerations: Extreme temperatures can affect the functionality of the ball valve. If you’re working in environments with high or low temperatures, ensure the valve is rated for such conditions.

-

Valve Lubrication: Ensure that your valve is properly lubricated to avoid stiffness and ensure smooth operation, especially in large-scale systems.

Troubleshooting and Maintenance

Ball valves are typically reliable, but over time, you may encounter issues where a valve won’t fully open or close. Here’s a breakdown of common problems and how to address them:

Common Issues

-

Valve Sticking or Seizing:

- Cause: Dirt, corrosion, or lack of lubrication can cause the valve to seize.

- Solution: Clean the valve thoroughly and lubricate it using appropriate valve grease.

-

Partial Closure:

- Cause: A worn-out seal or internal damage to the ball can prevent the valve from closing completely.

- Solution: Inspect and replace seals or the ball as needed.

-

Leakage:

- Cause: A leaking valve may indicate worn seals, dirt, or corrosion on the valve seat.

- Solution: Clean the valve, replace the seals, and ensure the seating surface is smooth.

Maintenance Tips

-

Regular Inspection: Periodically inspect the valve for any signs of wear and tear. This includes checking the handle, seals, and any external indicators.

-

Cleaning: Regularly clean the valve, especially in environments with high levels of particulate matter. This will help prevent clogging and ensure smooth operation.

-

Sealing: For valves exposed to harsh chemicals or extreme temperatures, use appropriate seals to protect the valve from damage.

Industry-Specific Applications

Ball valves are versatile and find applications in several industries. Here are some examples of how they’re used in various sectors:

Oil & Gas Industry

In the oil and gas industry, ball valves control the flow of petroleum and natural gas. These valves are crucial in pipeline systems, refineries, and storage tanks. Their ability to handle high pressures and temperatures makes them ideal for such applications.

Chemical Processing

Ball valves are widely used in chemical plants for controlling the flow of chemicals and corrosive liquids. Stainless steel ball valves are commonly used in these environments due to their resistance to corrosion and their ability to handle aggressive substances.

Water Treatment

Ball valves are essential in water treatment plants, where they regulate the flow of water throughout the system. Their simple design makes them easy to maintain and highly reliable for managing large-scale water flows.

FAQ (Frequently Asked Questions)

What Happens If a Ball Valve Is Left Partially Open?

Leaving a ball valve partially open can cause problems such as reduced flow efficiency, potential pressure build-up, and wear on internal components. It’s always best to fully open or fully close the valve to ensure optimal performance.

How Do I Fix a Ball Valve That Is Stuck?

If a ball valve is stuck, you can try the following:

- Lubricate the valve to loosen up any debris or corrosion.

- If lubrication doesn’t work, gently tap the valve with a rubber mallet.

- If the valve still doesn’t budge, it may require professional servicing or replacement.

Conclusion

Knowing how to check whether a ball valve is open or closed is essential for maintaining a smooth and safe operation. By following these tips, you can ensure your valves function properly and avoid costly failures.