Top Chinese Instrumentation Needle Valve Supplier – Wholesale & OEM Available

- 15 + Years Manufacturer, based in China

- Trusted by global OEMs & valve wholesalers

- Custom stainless steel needle valves

- Fast delivery · Low MOQ · ISO 9001 Certified

Leading Supplier of Instrumentation Needle Valves in China

An instrumentation needle valve is a type of valve used to precisely regulate fluid flow in systems where accurate control is essential.

It features a slender, tapered needle-like plunger that fits into a corresponding seat within the valve body. By turning the valve handle, the needle is gradually moved into or out of the seat, allowing very fine control over flow rates.

Beyond Fluid’s high quality instrumentation needle valves are compatiable with Swagelok, and have been well accepted and widely used in a variety of industries for many years. like oil and gas, chemical processing, and laboratories, especially for applications requiring precise flow measurement and control under high pressure.

Feature:

- Technical: Forged/Barstock

- Size: 1/8″-1″/6mm-28mm

- Packing Material: PTFE, PEEK

- Material: 316, 316L, 304, 304L, 321, 904L, brass, F91, F92, duplex 2205 Titanium, alloy 20, alloy 400, alloy 600, alloy C-276 material

- Connection: Thread, Twin-ferrule & Single-ferrule, Butt Weld

- Max. working pressure: 10000 psig (690 bar)

- Working Temperature: -28~649°C (-65~1200°F)

- Packaging: single bagged with inner box and outer carton

- Traceability: Critical surfaces are 100% visually inspected using magnification and lighting

- Test: All valves 100% factory tested and come with high-quality appearance

Hot-Selling Types Of Instrumentation Needle Valves

Connection: NPT, BSP | Pressure: 1000 PSI, 3000 PSI, 6000 PSI | Size: 1/8"-1"/6mm-20mm | Material: SS304, SS316, Alloy

Connection: double ferrule | Pressure: 1000 PSI, 3000 PSI, 6000 PSI | Size: 1/8"-1"/6mm-20mm | Material: SS304, SS316, Alloy

Connection: double ferrule | Pressure: 1000 PSI, 3000 PSI, 6000 PSI | Size: 1/8"-1"/6mm-20mm | Material: SS304, SS316, Alloy

Connection: double ferrule | Pressure: 1000 PSI, 3000 PSI, 6000 PSI | Size: 1/8"-1"/6mm-20mm | Material: SS304, SS316, Alloy

Connection: NPT, BSPT | Pressure: 1000 PSI, 3000 PSI, 6000 PSI | Size: 1/8"-1"/6mm-20mm | Material: SS304, SS316, Alloy

Connection: butt weld | Pressure: 1000 PSI, 3000 PSI, 6000 PSI | Size: 1/8"-1"/6mm-20mm | Material: SS304, SS316, Alloy

Connection: NPT, BSPT | Pressure: 1000 PSI, 3000 PSI, 6000 PSI | Size: 1/8"-1"/6mm-20mm | Material: SS304, SS316, Alloy

Connection: NPT, BSPT | Pressure: 1000 PSI, 3000 PSI, 6000 PSI | Size: 1/8"-1"/6mm-20mm | Material: SS304, SS316, Alloy

Features of Integral Bar Stock Needle Valves(6000 PSI)

- Cold drawn bar.

- Panel mounting available as an option.

- Integrated valve body structure, leak free design.

- Handle of different colors available for option.

- Leak-tight performance testing for every valve at the maximum working pressure with nitrogen.

- Maximum working pressure:

- Stainless steel: 6000 psig (414 bar)

- Alloy C-276: 6000 psig (414 bar)

- Alloy 400: 5000 psig (345 bar)

- Titanium: 5000 psig (345 bar)

- Brass: 3000 psig (207 bar)

- Working temperature:

- PTFE: -65°F to 450°F (-54°C to 232°C)

- PEEK: -65°F to 500°F (-54°C to 260°C)

- Graphite: -65°F to 1200°F (-54°C to 649°C)

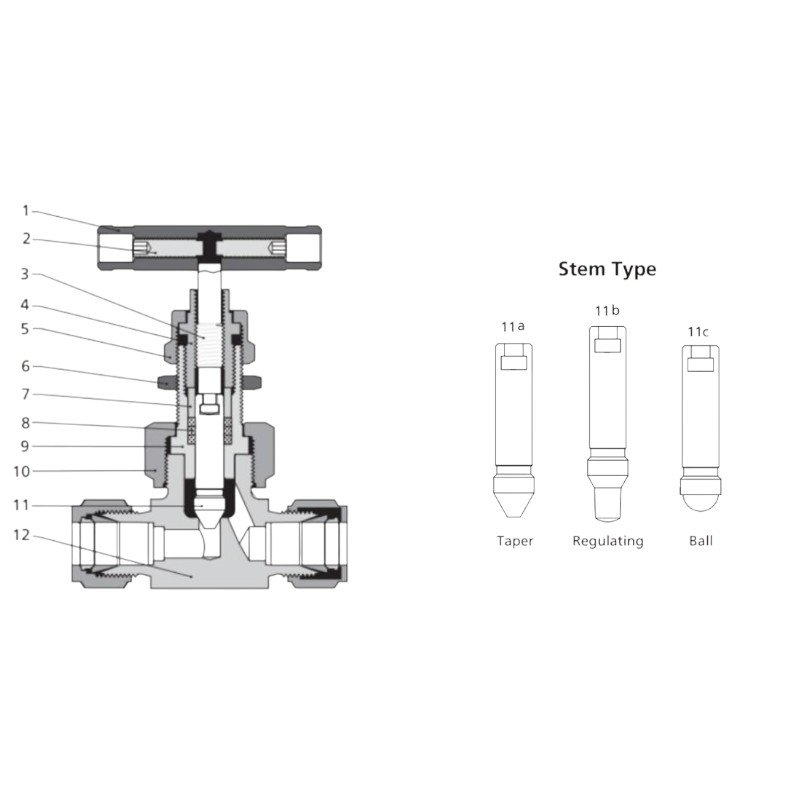

Construction

| NO. | Component | Material | ||

|---|---|---|---|---|

| 316 SS | Brass | Alloy 400 | ||

| 1 | Handle | Anodized aluminum or stainless steel | ||

| 2 | Packing Nut | 316 SS/A276 | Brass 36000/B16 | Alloy 400/B164 |

| 3 | Packing Spring | S17700/A693 | ||

| 4 | Upper Packing | PTFE or PEEK or graphite | ||

| 5 | Lower Packing | PTFE or PEEK or graphite | ||

| 6 | Set Screw | Stainless steel | ||

| 7 | Packing Washer | 316 SS/A276 | Brass 36000/B16 | Alloy 400/B164 |

| 8 | Panel Nut | Stainless Steel | Brass 36000 | Stainless Steel |

| 9 | Stem | 316 SS/A276 | 304 SS/A276 | Alloy 400/B164 |

| 10 | Body | 316 SS/A276 | Brass 36000/B16 | Alloy 400/B164 |

☉ Note: The BFN series needle valves default to panel installation structure when leaving the factory.

Features of Integral Bonnet Needle Valves(3000 PSI & 5000 PSI)

- One-piece forged body.

- Easy external adjustments by packing nut.

- Compact design.

- Handle of different colors available for option.

- Leak-tight performance testing for every valve at the maximum working pressure with nitrogen.

- Maximum working pressure:

- BN Series (Soft sealing): 3000 psig (207 bar)

- BNH Series (Hard sealing): 5000 psig (345 bar)

- Working temperature:

- PTFE: -65°F to 450°F (-54°C to 232°C)

- PEEK: -65°F to 500°F (-54°C to 260°C)

Construction

| NO. | Component | Material | ||

|---|---|---|---|---|

| 316 SS | Brass | Alloy 400 | ||

| 1 | Handle | Anodized aluminum or stainless steel or black knob | ||

| 2 | Set Screw | Stainless steel | ||

| 3 | Packing Bolt | 316 SS/A276 | Brass 36000/B16 | Alloy 400/B164 |

| 4 | Washer | 316 SS/A276 | ||

| 5 | Packing Spring | S17700/A693 | ||

| 6 | Washer | 316 SS/A276 | ||

| 7 | Upper Packing | PTFE/PEEK | ||

| 8 | Lower Packing | PTFE/PEEK | ||

| 9 | Packing Washer | 316 SS/A276 | ||

| 10 | Panel Nut | 316 SS/A276 | ||

| 11 | Stem | 316 SS/A276 | 304 SS/A276 | Alloy 400/B164 |

| 12 | Body | 316 SS/A276 | Brass 36000/B16 | Alloy 400/B164 |

☉ Note: The BN/BNH series needle valves default to panel installation structure when leaving the factory.

Features of Union Bonnet Needle Valves(6000 PSI & 10000 PSI)

- One-piece forged body.

- Two-stem design: thread hardened upper stem and smooth surface hardened lower stem.

- Accidental valve disassembly disabled by union bonnet construction.

- Safety back seating seal in fully open position.

- Panel mounting available as an option.

- Handle color options are available.

- Linearly instead of helical movement of the nonrotating lower stem, avoiding galling damage to packing and tip.

- Leak-tight performance testing for every valve at the maximum working pressure with nitrogen.

- Maximum working pressure:

- UN Series: 6000 psig (414 bar)

- UNH Series: 10000 psig (689 bar)

- Working temperature:

- PTFE: -65°F to 450°F (-54°C to 232°C)

- PEEK: -65°F to 500°F (-54°C to 260°C)

- Graphite: -65°F to 1200°F (-54°C to 649°C)

Construction

| NO. | Component | Material | ||

|---|---|---|---|---|

| 316 SS | F91 | Alloy C-276 | ||

| 1 | Handle | Anodized aluminum or stainless steel | ||

| 2 | Set Screw | Stainless steel | ||

| 3 | Upper Stem | 316 SS/A276 | F91/A182 | C-276/B574 |

| 4 | Packing Bolt | 316 SS/A276 | F91/A182 | C-276/B574 |

| 5 | Lock Nut | 304 SS/A276 | ||

| 6 | Panel Nut | 304 SS/A276 | ||

| 7 | Gland | 316 SS/A276 | F91/A182 | C-276/B574 |

| 8 | Packing | PTFE or PEEK or graphite | ||

| 9 | Bonnet | 316 SS/A276 | F91/A182 | C-276/B574 |

| 10 | Union Nut | 316 SS/A276 | F91/A182 | C-276/B574 |

| 11 | Lower Stem | Chrome-plated 316 SS/A276 | Chrome-plated F91/A182 | C-276/B574 |

| 12 | Body | 316 SS/A182 | F91/A182 | F92/A182 |

☉ Note: The UN/UNH series needle valves default to panel installation structure when leaving the factory.

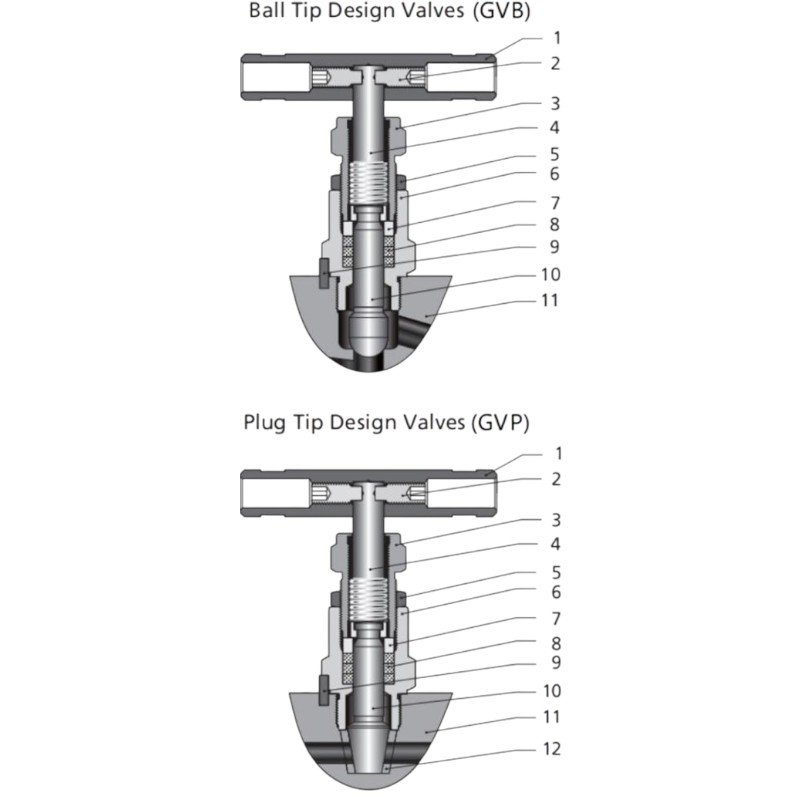

Features of Gauge Valves(6000 PSI)

- Cold drawn square bar.

- Non-rotating lower stem, ball tip and plug tip designs.

- Variety of materials for seat and packing.

- Safety back seating seals in fully open position.

- Rolled spindle operating threads.

- Lubricant for stem thread isolated from the media.

- Bonnet locking pin fitted as standard.

- Low torque operating T bar handle.

- Leak-tight performance testing for every valve at the maximum working pressure with nitrogen.

- Maximum working pressure: 6000 psig (414 bar).

- Working temperature:

- GVB Series:

- PTFE: -65°F to 450°F (-54°C to 232°C)

- Graphite: -65°F to 1200°F (-54°C to 649°C)

- GVP Series:

- Acetal seat: -20°F to 250°F (-28°C to 121°C)

- PEEK Seat: -20°F to 400°F (-28°C to 204°C)

- PFA Seat: -20°F to 400°F (-28°C to 204°C)

- GVB Series:

Construction

| Item | Part | Valve Body Material | |

|---|---|---|---|

| SS 316 | Alloy 400 | ||

| 1 | Handle | Anodized aluminum | |

| 2 | Set Screw | Stainless steel | |

| 3 | Packing Bolt | SS 304 | |

| 4 | Upper Stem | SS 316 | |

| 5 | Lock Nut | 17-4PH | |

| 6 | Bonnet | SS 316 | Alloy 400 |

| 7 | Gland | SS316 | |

| 8 | Packing | PTFE or graphite | |

| 9 | Lock Pin | Stainless steel | |

| 10 | Lower Stem | SS 316 | Alloy 400 |

| 11 | Body | SS 316 | Alloy 400 |

| 12 | Seat | Acetal or PEEK or PFA | |

Manufacturing Process For Instrument Needle Valves At Beyond Fluid

At Beyond Fluid, we take great care in manufacturing our instrument valves. From the first mold to the final packaging, every step is closely monitored to ensure strict quality control. This meticulous process guarantees that our products meet the highest standards of excellence.

- Design and Engineering

- Material Procurement

- CNC machining

- Heat Treatment (Selective)

- Cleaning and Surface Treatment

- Assembly

- Testing

- Marking and Tracebility

- Packaging

Who We Are

Beyond Fluid, Your Reliable Instrumenation Needle Valves Manufacturer

Beyond Fluid has over 15 years of experience supplying stainless steel instrumentation valves and fittings to wholesalers, distributors, and large contractors. We offer reliable quality, excellent service, on-time delivery, and competitive prices. Our commitment to advanced technology, precision engineering, and strict quality standards ensures we meet the diverse needs of customers worldwide.

We take pride in producing high-quality instrumentation valves and fittings. Our comprehensive range of products is designed for optimal performance and durability, with both standard and customized solutions. We aim to be your long-term trusted partner to expand your market presence.

Why Choose Us

Reliability. Consistency. Integrity

When you choose Beyond Fluid, you ensure precision and reliability, backed by our strict Quality Assurance Program.

Beyond Fluid ensures reliability with a 99.99% on-time delivery rate and quick response to urgent orders through stocked materials.

Our robust manufacturing and supply chain enable us to offer competitive prices, helping clients expand their market reach.

Our expert engineers offer design, CAD, and technical support, while our trained sales team ensures fast, efficient 24-hour responses.

Testimonials

What Our Clients Say

A Large Wholesaler From USA

“We’re literally satisfied with Beyond Fluid’ always on-time delivery and exceptional handling of requests. Their commitment to timely service is evident and consistently reliable. Their swift response and guaranteed on-time delivery make them my preferred choice.”

A Brand Manufacturer From Germany

“We can always count on Beyond Fluid’s quality. During a 2018 visit, their advanced facilities and stringent quality controls made a lasting impression on us. Their timely responses to requests for drawings or technical support further solidify my trust. We really love to place our orders to those suppliers like Beyond Fluid.”

FAQ

Frequently Asked Questions.

Here are a few real most popluar questions from our clients.

Yes, Beyond Fluid's instrumentation needle valves are fully compatible with other big brands, like Swagelok and can be easily integrated into existing systems, offering customers flexibility and ease of use.

Sure, we provide OEM services for several leading global brands in instrumentation needle valves, significantly reducing their production costs and helping them gain greater market share.

Our instrumentation needle valves follow strict quality control protocols and meet industry-leading standards, ensuring consistent performance and dependable reliability.

If you receive defective products, no worries! We offer a customer-friendly policy: we’ll either send a free replacement or issue a credit right away. We're committed to making things right for you.

- High quality consistency.

- On-time delivery.

- Affordable price.

- Excellent service and added value.

Thanks to our excellent supply chain management, and more than 15 years of experience in production, most of our wholesalers and distributors are happy with our prices.

Our typical payment term is 30% T/T in advance, balance payment against BL copy. But for serious buyers/companies, we’re open to discussing more flexible payment terms, such as a 30% deposit with the balance due within 30 days after shipment. We can work out the details later.