Proportional relief valves are vital in modern industrial systems. They protect sensitive equipment by maintaining pressure levels within a safe range, reducing risks of damage and downtime.

Proportional relief valves are designed to modulate the flow of fluid based on pressure fluctuations, ensuring smooth and safe system operation.

Explore their features, applications, and a comprehensive installation guide to maximize their benefits.

How Do Proportional Relief Valves Work?

Proportional relief valves maintain system safety by modulating flow based on pressure changes. This precision makes them ideal for pressure-sensitive operations.

When upstream pressure exceeds a set limit, these valves open proportionally to release excess pressure, preventing system overload.

The Working Mechanism of Proportional Relief Valves

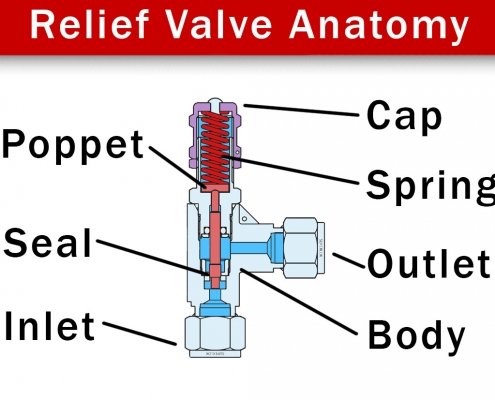

Proportional relief valves operate using a spring-loaded mechanism. Here’s how they work:

- Pressure Detection: The upstream pressure applies force on a diaphragm or piston.

- Valve Opening: Once the pressure exceeds the spring’s set resistance, the valve begins to open gradually.

- Proportional Control: The valve modulates flow based on the extent of the pressure, rather than fully opening all at once.

- Resealing: When the pressure returns to acceptable levels, the valve reseals tightly.

This proportional action reduces the risk of sudden pressure surges, offering smoother protection compared to traditional relief valves.

| Feature | Proportional Relief Valves | Traditional Relief Valves |

|---|---|---|

| Flow Modulation | Proportional | Binary (On/Off) |

| Sensitivity to Pressure | High | Moderate |

| Application Versatility | Broad | Limited |

Key Features of R-Series Proportional Relief Valves

Choosing the right valve depends on understanding its capabilities. The R-Series is engineered for reliability and performance.

The R-Series features precise opening pressures, tight sealing, and diverse end connection options, making it a versatile choice for industrial systems.

Understanding the Key Features

-

Reliable Opening and Resealing Pressure

R-Series valves provide consistent performance with minimal variation in opening and resealing pressure. This reliability reduces the need for frequent adjustments. -

Tight Sealing Design

The advanced sealing mechanism prevents leaks, enhancing safety and reducing wastage. Various sealing materials, such as PTFE and Viton, are available to handle different fluids and temperatures. -

Versatile End Connections

Whether you need threaded, flanged, or welded connections, the R-Series offers a wide range of configurations to ensure compatibility with your system.

These features make the R-Series an excellent investment for maintaining efficiency and safety.

Applications of Proportional Relief Valves

Proportional relief valves are found across various industries. Their adaptability and precision make them invaluable in many systems.

From test environments to heating pipelines, these valves play a critical role in ensuring pressure consistency and safety.

Industry-Specific Applications

-

Testing Laboratories

Proportional relief valves maintain stable pressure levels during equipment testing. This stability ensures accurate results and prevents damage to sensitive devices. -

Steam Cleaning and Sterilization Systems

In environments with variable steam conditions, these valves release excess pressure to prevent system failures. -

Heating Pipelines

Overpressure can cause leaks or equipment failure. Proportional relief valves help maintain optimal pressure for smooth operations. -

Distribution and Filling Systems

These valves ensure consistent flow and pressure during the transfer and filling of fluids, improving operational efficiency.

Installation and Maintenance Guide

Proper installation and maintenance are crucial for maximizing valve performance and longevity.

Follow step-by-step instructions to install proportional relief valves and maintain them effectively, ensuring long-term reliability.

Tips for Installation and Maintenance

-

Installation Steps

- Preparation: Ensure the system is depressurized and clean before installation.

- Orientation: Install the valve in the correct position as per manufacturer guidelines.

- Tightening: Secure the connections without overtightening to prevent damage.

- Testing: Check for leaks and ensure proper function after installation.

-

Maintenance Tips

- Regularly inspect the valve for wear and tear.

- Clean the internal components to prevent debris buildup.

- Calibrate the valve periodically to maintain accurate pressure settings.

-

Troubleshooting Common Issues

- Leakage: Inspect seals and replace if necessary.

- Inconsistent Operation: Check for clogging or spring fatigue.

- Pressure Setpoint Drift: Recalibrate to restore precision.

Frequently Asked Questions

Selecting the right valve can be challenging. Here are answers to common questions.

Understand compatibility, adjustment procedures, and how to identify the best valve for your system.

Common Questions Answered

-

How do I choose the correct valve size?

Choose a valve based on your system’s maximum pressure and flow rate requirements. Oversizing or undersizing can impact performance. -

Can proportional relief valves handle corrosive fluids?

Yes, provided the valve materials are compatible. Options like stainless steel and PTFE seals are ideal for corrosive applications. -

How do I adjust the pressure setpoint?

Most valves include an adjustment screw. Turn clockwise to increase the setpoint and counterclockwise to decrease it. -

What certifications should I look for?

Look for ISO, ASME, or other relevant certifications to ensure quality and compliance.

Comparison with Other Valve Types

Proportional relief valves differ significantly from traditional relief valve types.

They provide smoother operation and better pressure control, but understanding their limitations is key to selecting the right solution.

Comparing Valve Types

| Aspect | Proportional Relief Valves | Spring-Loaded Relief Valves | Pilot-Operated Relief Valves |

|---|---|---|---|

| Flow Control | Proportional | On/Off | Proportional |

| Sensitivity to Pressure | High | Medium | High |

| Maintenance Requirements | Low | Moderate | High |

| Cost | Moderate | Low | High |

Each type has its niche. Choose based on your application needs and budget constraints.

Conclusion

Proportional relief valves offer precise control, reliability, and versatility. Assess your system’s needs and explore how these valves can enhance safety and efficiency in industrial applications.