Sanitary Fittings Manufacturer in China

Sanitary fittings are hygienic pipe components designed for clean and secure connections in sanitary processing systems.

They are widely used in food, beverage, dairy, pharmaceutical, and biotechnology applications.

What Are Sanitary Fittings?

Sanitary fittings, also known as hygienic fittings, are stainless steel pipe components used to connect, extend, or change the flow direction in sanitary processing systems.

Unlike standard industrial fittings, sanitary fittings feature smooth internal surfaces, precise machining, and hygienic design to minimize product residue and reduce the risk of contamination.

They are typically manufactured from SS316L stainless steel and are suitable for CIP (Clean-in-Place) and SIP (Sterilize-in-Place) processes, making them widely used in food, beverage, dairy, pharmaceutical, and biotechnology industries.

Feature:

- Technical: Barstock and Forging

- Size: 1/2″-12″/DN10-DN250

- Material: SS304/1.4301, SS316L/1.4404

- Standard: 3A, AS, BPE, DIN, ISO, SMS, RJT, IDF, MACON etc

- Connection: thread, weld, tri-clamp, flange

- Working Pressure: 150 psi (10 bar) to 300 psi (20 bar)

- Working Temperature: -20°F (-29°C) to 400°F (204°C)

- Application: Food, beverage, wine, pharmaceutical and chemical industries

Hot-Selling Types of Sanitary Fittings

Size: 1/2"-4" / DN10-DN100

Material: SS304, SS316L

Standard: DIN, IDF, BS, RJT, SMS

Size: 1/2"-4" / DN10-DN100

Material: SS304, SS316L

Standard: DIN, IDF, BS, RJT, SMS

Size: 1/2"-6" / DN10-DN150

Material: SS304, SS316L

Standard: 3A, ASM BPE, DIN, BS, SMS

Technical Specifications of Sanitary Fittings

| Parameter | Specification |

|---|---|

| Material | SS304, SS316L |

| Size Range | 1/2" – 6" / DN10 – DN150 |

| Connection Type | Tri-Clamp, Butt Weld, Union, thread |

| Surface Finish | Ra ≤ 0.8 μm (Optional Ra ≤ 0.4 μm) |

| Manufacturing Process | CNC Machining & Precision Polishing |

| Standards | 3A, ASME BPE, DIN, IDF, SMS |

| Cleaning Method | CIP / SIP Compatible |

| Applications | Food, Beverage, Dairy, Pharmaceutical, Biotechnology |

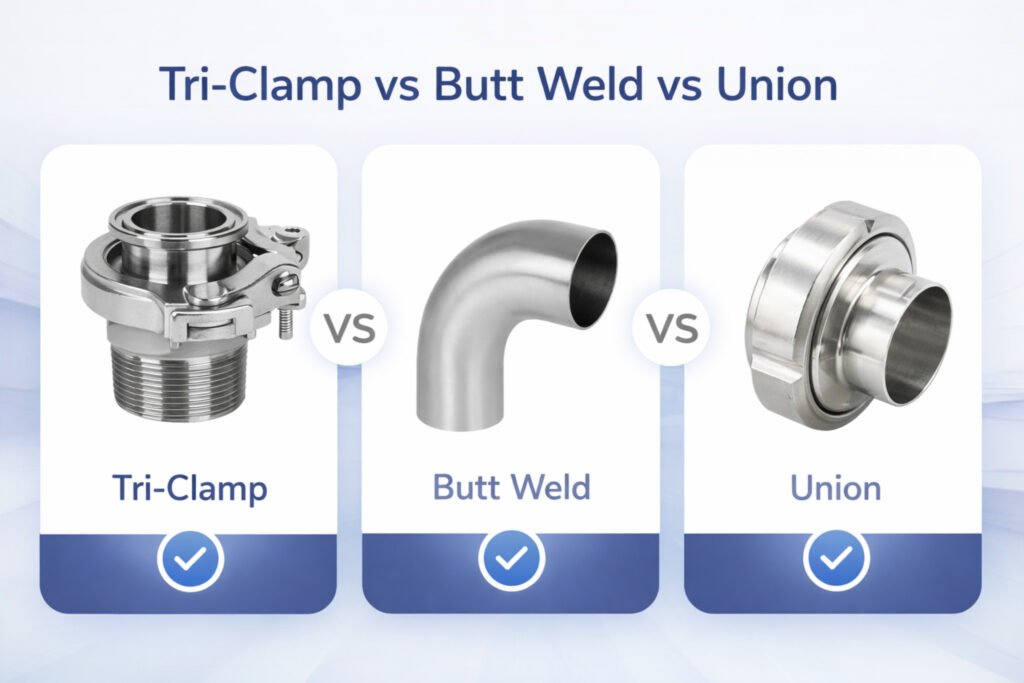

Sanitary Fitting Connection Types

Sanitary fittings are available with different connection types to meet specific hygienic, cleaning, and installation requirements in sanitary processing systems.

Sanitary Tri-Clamp Connection

Tri-clamp (also known as tri-clover) connections are the most commonly used sanitary fitting connections. They allow quick assembly and disassembly without special tools, making them ideal for systems requiring frequent cleaning or maintenance.

- ✓ Quick-release and easy installation

- ✓ Excellent for CIP & SIP processes

- ✓ Widely used in food, beverage, dairy, and pharmaceutical industries

Sanitary Butt Weld Connection

Butt weld connections provide a permanent, leak-free joint by welding fittings directly to pipes. This connection type offers the highest level of hygiene with no crevices, making it suitable for critical sanitary applications.

- ✓ Smooth internal surface with no dead space

- ✓ Ideal for high-purity and pharmaceutical systems

- ✓ Complies with 3A and ASME BPE standards

Sanitary Union Connection

Sanitary union connections allow pipelines to be easily disconnected while maintaining a hygienic seal. They are often used where components need to be removed or replaced regularly.

- ✓ Easy disassembly for maintenance

- ✓ Secure and hygienic sealing design

- ✓ Commonly used in modular processing systems

Threaded Sanitary Connection

Threaded sanitary fittings are designed for specific low-pressure hygienic applications. They are typically used in auxiliary lines or non-product contact areas.

- ✓ Simple installation

- ✓ Suitable for secondary hygienic applications

- ✓ Not recommended for high-purity processes

Standards & Certifications

All sanitary fittings are manufactured in accordance with internationally recognized hygienic and quality standards to ensure product safety, cleanability, and regulatory compliance.

3A Sanitary Standards

3A Sanitary Standards are widely recognized in food, beverage, wine, and dairy industries, focusing on hygienic equipment design and cleanability.

- Smooth, crevice-free internal surfaces

- Designed to minimize product residue and bacterial growth

- Suitable for food, beverage, and dairy processing systems

FDA Compliance

FDA compliance ensures that materials used in sanitary fittings are safe for direct contact with food, beverage, and pharmaceutical products.

- FDA-compliant materials for wetted parts and seals

- Safe for direct contact with consumable products

- Common requirement for hygienic processing applications

CE & ISO 9001 Certification

CE and ISO 9001 certifications demonstrate compliance with European regulations and recognized quality management systems.

- CE marking for conformity with EU safety requirements

- ISO 9001 certified manufacturing and quality control system

- Consistent product quality and full material traceability

How to Choose the Right Sanitary Fittings?

Selecting the right sanitary fittings depends on hygienic requirements, installation method, applicable standards, and material compatibility with the process media.

Choose by Connection Type

Tri-Clamp Fittings are ideal for systems requiring frequent disassembly and cleaning. They are widely used in food, beverage, and dairy processing.

Butt Weld Fittings provide permanent, crevice-free connections, making them suitable for high-purity and pharmaceutical applications.

Sanitary Union Fittings allow easy pipeline disconnection while maintaining hygienic sealing, commonly used in modular processing systems.

Choose by Applicable Standards

DIN, SMS, IDF standards are commonly used in European food and beverage processing systems.

3A and ASME BPE standards are preferred for applications with strict hygienic and cleanability requirements, such as dairy and pharmaceutical processing.

Choose by Material

SS304 sanitary fittings are suitable for general food and beverage applications with mild processing conditions.

SS316L sanitary fittings offer superior corrosion resistance and are recommended for dairy, pharmaceutical, and biotechnology applications.

Choose by Surface Finish

A surface finish of Ra ≤ 0.8 μm is suitable for most sanitary processing systems and standard CIP cleaning.

For high-purity or pharmaceutical applications, Ra ≤ 0.4 μm is recommended to further reduce contamination risk and improve cleanability.

Technical Support

At Beyond Fluid, we pride ourselves on our comprehensive expertise in engineering and designing stainless steel sanitary fittings. From the initial concept to the final product, our team is equipped to transform your ideas into tangible, high-quality hydraulic solutions. Our commitment to innovation ensures that we deliver not just products, but value-driven solutions tailored to your needs.

- Tailored Solutions

- Techical Support

- Free Drawings Service

Who We Are

Beyond Fluid, Your Reliable Stainless Steel Sanitary Fittings Manufacturer

Beyond Fluid has over 15 years of experience supplying stainless steel sanitary fittings and ball valves to wholesalers, distributors, and large contractors. We offer reliable quality, excellent service, on-time delivery, and competitive prices. Our commitment to advanced technology, precision engineering, and strict quality standards ensures we meet the diverse needs of customers worldwide.

We take pride in producing high-quality sanitary fittings and valves. Our comprehensive range of products is designed for optimal performance and durability, with both standard and customized solutions. Serving industries from food and beverage to biotechnology, we aim to be your long-term trusted partner to expand your market presence.

Why Choose Us

Reliability. Consistency. Integrity

When you choose Beyond Fluid, you ensure precision and reliability, backed by our strict Quality Assurance Program.

Beyond Fluid ensures reliability with a 99.99% on-time delivery rate and quick response to urgent orders through stocked materials.

Our robust manufacturing and supply chain enable us to offer competitive prices, helping clients expand their market reach.

Our expert engineers offer design, CAD, and technical support, while our trained sales team ensures fast, efficient 24-hour responses.

Testimonials

What Our Clients Say

A Large Wholesaler From USA

“We’re literally satisfied with Beyond Fluid’ always on-time delivery and exceptional handling of requests. Their commitment to timely service is evident and consistently reliable. Their swift response and guaranteed on-time delivery make them my preferred choice.”

A Brand Manufacturer From Germany

“We can always count on Beyond Fluid’s quality. During a 2018 visit, their advanced facilities and stringent quality controls made a lasting impression on us. Their timely responses to requests for drawings or technical support further solidify my trust. We really love to place our orders to those suppliers like Beyond Fluid.”

FAQ

Frequently Asked Questions.

Here are a few real most popluar questions from our clients.

Beyond Fluid manufacture and supply all kinds of sanitary fittings, such as sanitary tri-clamp fittings, sanitary unions, sanitary hose couplings, sanitary butt weld fittings and other more sanitary pipe fittings. All our products meet industry standards for hygiene and durability.

Yes, we provide OEM services to help our clients reduce production costs and enhance their market share. We can customize products based on your specifications, including branding and packaging.

Our sanitary fittings are manufactured to comply with industry standards such as ISO, CE, FDA, and 3-A. Specific certifications can be provided upon request.

We use high-grade stainless steel, such as 304 and 316/316L, which ensures excellent corrosion resistance, hygiene, and longevity for use in sanitary applications.

Absolutely. With over 15 years of manufacturing experience, we are equipped to handle large-scale orders and provide timely delivery for wholesalers, distributors, and contractors.

Yes, we can provide samples for quality evaluation. Please contact us to discuss your sample requirements and terms.

Thanks to our excellent supply chain management, and more than 15 years of experience in production, most of our wholesalers and distributors are happy with our prices.

Our typical payment term is 30% T/T in advance, balance payment against BL copy. But for serious buyers/companies, we’re open to discussing more flexible payment terms, such as a 30% deposit with the balance due within 30 days after shipment. We can work out the details later.