Beyond Fluid, Sanitary Ball Valves Manufacturer in China

For over 15 years, we have been a trusted supplier of sanitary ball valves to wholesalers, distributors, and large contractors worldwide. Our mission is to solve your supply challenges and help expand your market share. Partner with Beyond Fluid to achieve lasting business success.

Leading Supplier of Sanitary Ball Valves in China

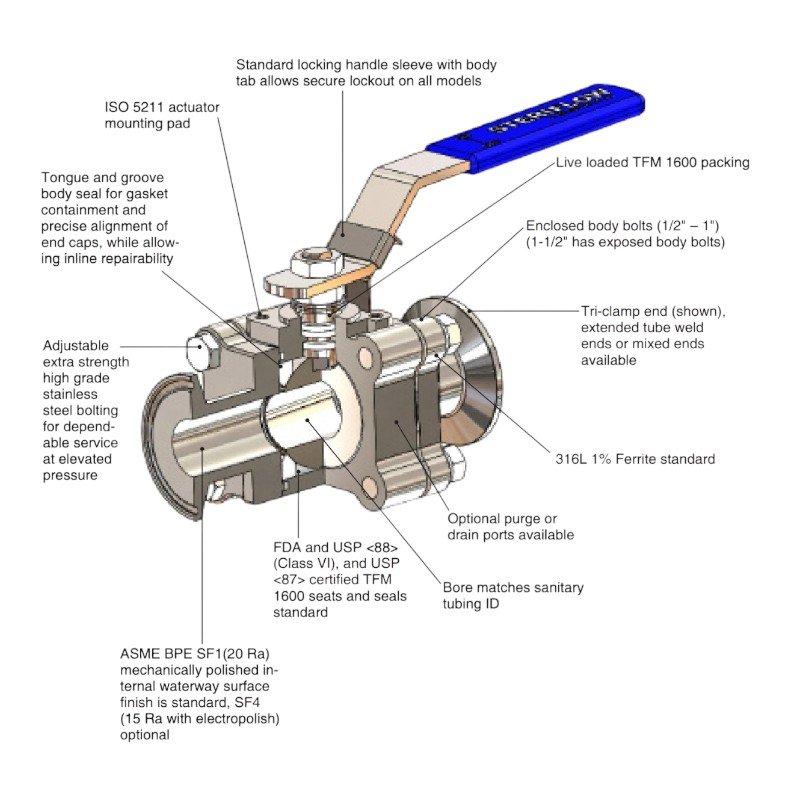

Beyond Fluid’s sanitary ball valves, made from 304SS or 316SS, feature standard electronic polishing for a smooth, clean surface, preventing media accumulation.

Ideal for food and biopharmaceutical applications, they support steam in-situ cleaning with seamless, self-draining flow channels. Available with various connection options—threaded, flanged, welded, clamped, or sleeve—the valve’s all-in-one ball seat design prevents liquid retention, making it suitable for biomedical engineering.

The stem is hermetically sealed for durability, low torque, and long-term high-temperature use, with interchangeable valve bodies for flexibility across applications.

Specifications:

- Technical: Investment Casting, Barstock, Forging

- Design: Encapsulated, half-pack

- Size: 1/2″-6″/DN15-DN150

- Material: SS304, SS316, SS316L

- Sealing Material: PTFE(FDA117.2600)

- Connection: thread, weld, trip clamp, flange

- Working Pressure: 0-10 Bar

- Working Temperature: -40° F to 302° F (-40° C to 150° C)

- Standard: 3A, DIN, SMS, IDF, RJT, BPE, ISO

- Application: Food, beverage, wine, pharmaceutical and chemical industries

Hot-Selling Types Of Sanitray Ball Valves

Design: 3 piece

Connection: Trip Clamp

Pressure: 0–10 Bar

Size: 1/2" – 6"

Material: SS304, SS316

Design: 3 piece

Connection: Trip Clamp

Pressure: 0–10 Bar

Size: 1/2" – 6"

Material: SS304, SS316

Design: 3 piece

Connection: Butt Weld

Pressure: 0–10 Bar

Size: 1/2" – 6"

Material: SS304, SS316

Design: 3 piece

Connection: Trip Clamp

Pressure: -1 Bar to 10 Bar

Size: KF10 to KF50

Material: SS304, SS316

Design: 3 piece

Connection: Flange

Pressure: 0–10 Bar

Size: 1/2" – 6"

Material: SS304, SS316

Design: 3 piece

Connection: Trip Clamp

Pressure: 0–10 Bar

Size: 1/2" – 6"

Material: SS304, SS316

Design: 2 piece

Connection: Trip Clamp

Pressure: 0–10 Bar

Size: 1/2" – 6"

Material: SS304, SS316

Design: 3 piece

Connection: Clamp, Thread

Pressure: 0 – 10 Bar

Size: 1/2" – 6"

Material: SS304, SS316

Design: 2 piece

Connection: Trip Clamp

Pressure: 0–10 Bar

Size: 1/2" – 6"

Material: SS304, SS316

Design: 3 piece

Connection: Trip Clamp

Pressure: 0–10 Bar

Size: 1/2" – 6"

Material: SS304, SS316

Shape: 3 way

Connection: Clamp

Pressure: 0 – 10 Bar

Size: 1/2" – 6"

Material: SS304, SS316

Shape: 4 way

Connection: Clamp

Pressure: 0 – 10 Bar

Size: 1/2" – 6"

Material: SS304, SS316

Manufacturing Process For Sanitary Ball Valves At Beyond Fluid

At Beyond Fluid, we take great care in manufacturing our sanitary ball valves. From the first mold to the final packaging, every step is closely monitored to ensure strict quality control. This meticulous process guarantees that our products meet the highest standards of excellence.

- Wax Mold

- Shelling

- Dewaxing

- Baking Model

- Casting

- Vibrating Shell

- Shot Blasting

- CNC Process

- Ultrasonic Cleaning

- Dust-Free Workshop Assembly

- QC Barometic Test

- Packing

Features of Sanitary Ball Valves

Sanitary ball valves are hygienic valves used in food, dairy, pharma, biotech, and cosmetics industries where cleanliness and sterility are essential.

Design & Structure

- Rotating ball with through-bore for quick on/off control.

- Smooth, crevice-free surfaces to avoid residue and bacteria.

- Common connections: Tri-Clamp, Flange and butt-weld.

Materials

- Stainless steel 304/316L, resistant to corrosion.

- Seals in FDA-approved PTFE, EPDM, or silicone.

Types

- Manual: Lever-operated.

- Automated: Pneumatic or electric actuators.

Design of Sanitary Tri-Clamp Ball Valves

- Stainless steel body (304/316L) — polished, crevice-free surfaces

- Full-port ball — unrestricted flow, quick 90° shutoff

- Food-grade seals (PTFE, EPDM, silicone) — tight closure, CIP/SIP ready

- Tri-clamp ends — fast, sanitary connection

- Manual or actuated — lever, pneumatic, or electric

- Standards — 3-A, FDA, ISO

Design of Sanitary Butt-Weld Ball Valves

- Butt-weld ends — permanent, crevice-free pipeline joints

- Stainless steel body (304/316L) — polished hygienic surfaces

- Full-port ball — unrestricted flow, no product retention

- Food-grade seals — PTFE, EPDM, silicone; CIP/SIP ready

- Operation — 90° lever or optional pneumatic/electric actuator

- Standards — 3-A, FDA, ISO, ASME BPE compliant

Design of Sanitary Flanged Ball Valves

- Flanged ends — sanitary flanges for secure, hygienic connections

- Stainless steel body (304/316L) — polished surfaces, corrosion-resistant

- Full-port ball — smooth flow, minimal pressure drop

- Food-grade seals — PTFE, EPDM, silicone; CIP/SIP compatible

- Operation — 90° lever; pneumatic/electric actuators available

- Standards — 3-A, FDA, ISO, ASME BPE compliant

- Applications — food, beverage, dairy, brewing, pharmaceutical

Advantages

Sanitary ball valves offer multiple benefits that make them ideal for hygienic and sterile process environments.

- Hygienic: Comply with 3A, FDA, and EHEDG standards; smooth surfaces minimize contamination risks.

- Easy Cleaning: Support CIP/SIP systems and quick disassembly, reducing downtime.

- Durable: Stainless steel construction with FDA-approved seals ensures long-lasting reliability.

- Efficient: Full-bore design delivers tight shutoff with minimal pressure drop.

- Versatile: Suitable for liquids, gases, and compatible with manual or automated systems.

Applications

Sanitary ball valves are widely applied across industries that demand high hygiene, sterility, and reliable flow control.

- Food & Beverage: Milk, beer, wine, juice, soft drinks, sauces, and edible oils—ensuring hygiene and flavor preservation.

- Dairy Processing: Yogurt, cheese, cream, and other sensitive products requiring sterile transfer.

- Pharmaceutical: Pure water, liquid medicines, and infusion solutions where sterility is critical.

- Biotechnology: Culture media, enzymes, and fermentation processes needing contamination-free handling.

- Cosmetics & Personal Care: Lotions, creams, and liquid soaps that must be produced in hygienic environments.

- Chemicals (Clean Grade): Specialty chemicals and solvents where purity and corrosion resistance are required.

Who We Are

Beyond Fluid, Your Reliable Sanitary Ball Valves Manufacturer

Beyond Fluid has over 15 years of experience supplying stainless steel sanitary ball valves to wholesalers, distributors, and large contractors. We offer reliable quality, excellent service, on-time delivery, and competitive prices. Our commitment to advanced technology, precision engineering, and strict quality standards ensures we meet the diverse needs of customers worldwide.

We take pride in producing high-quality sanitary ball valves and fittings. Our comprehensive range of products is designed for optimal performance and durability, with both standard and customized solutions. Serving industries from Food, wine, beverage to pharmaceuticals, we aim to be your long-term trusted partner to expand your market presence.

Why Choose Us

Reliability. Consistency. Integrity

When you choose Beyond Fluid, you ensure precision and reliability, backed by our strict Quality Assurance Program.

Beyond Fluid ensures reliability with a 99.99% on-time delivery rate and quick response to urgent orders through stocked materials.

Our robust manufacturing and supply chain enable us to offer competitive prices, helping clients expand their market reach.

Our expert engineers offer design, CAD, and technical support, while our trained sales team ensures fast, efficient 24-hour responses.

Testimonials

What Our Clients Say

A Large Wholesaler From USA

“We’re literally satisfied with Beyond Fluid’ always on-time delivery and exceptional handling of requests. Their commitment to timely service is evident and consistently reliable. Their swift response and guaranteed on-time delivery make them my preferred choice.”

A Brand Manufacturer From Germany

“We can always count on Beyond Fluid’s quality. During a 2018 visit, their advanced facilities and stringent quality controls made a lasting impression on us. Their timely responses to requests for drawings or technical support further solidify my trust. We really love to place our orders to those suppliers like Beyond Fluid.”

FAQ

Frequently Asked Questions.

Here are a few real most popluar questions from our clients.

We manufacture a wide range of stainless steel sanitary ball valves, including clamp ball valves, butterfly ball valves, tank bottom ball valves, welded ball valves, vacuum ball valves and flanged ball valves. All our products meet industry standards for hygiene and durability.

Yes, we provide OEM services to help our clients reduce production costs and enhance their market share. We can customize products based on your specifications, including branding and packaging.

Our sanitary ball valves are manufactured to comply with industry standards such as ISO, CE, FDA, and 3-A. Specific certifications can be provided upon request.

We use high-grade stainless steel, such as 304 and 316/316L, which ensures excellent corrosion resistance, hygiene, and longevity for use in sanitary applications.

Absolutely. With over 15 years of manufacturing experience, we are equipped to handle large-scale orders and provide timely delivery for wholesalers, distributors, and contractors.

Yes, we can provide samples for quality evaluation. Please contact us to discuss your sample requirements and terms.

Thanks to our excellent supply chain management, and more than 15 years of experience in production, most of our wholesalers and distributors are happy with our prices.

Our typical payment term is 30% T/T in advance, balance payment against BL copy. But for serious buyers/companies, we’re open to discussing more flexible payment terms, such as a 30% deposit with the balance due within 30 days after shipment. We can work out the details later.