Ball valves are everywhere, but do you know the differences between them?

Ball valves come in various types, including full port, reduced port, one – piece, two – piece, and three – piece designs, each suited for specific applications.

Understanding these differences can help you choose the right valve for your needs. Let’s dive into the details.

Full Port vs. Reduced Port Ball Valves: Which One Should You Choose?

Are you confused about full port and reduced port ball valves?

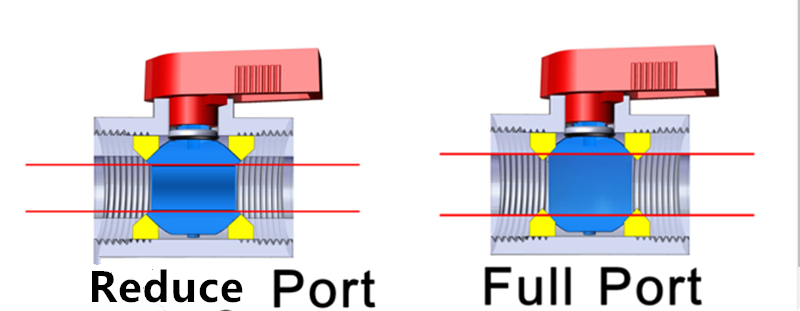

Full port ball valves have the same internal diameter as the pipeline, ensuring unrestricted flow, while reduced port valves have a smaller diameter, offering cost savings in large – scale applications.

For example, an 8” reduced port valve might match a 6” pipe diameter, making it a budget – friendly option. Full port valves are ideal for systems requiring maximum flow, while reduced port valves are better for cost – sensitive projects.

Key Differences:

- Flow Capacity: Full port valves allow unrestricted flow, while reduced port valves restrict flow slightly.

- Cost: Reduced port valves are more economical, especially in larger sizes.

- Applications: Full port valves are used in systems requiring high flow rates, while reduced port valves are suitable for general – purpose applications.

One – Piece, Two – Piece, and Three – Piece Ball Valves: What’s the Difference?

What’s the best ball valve configuration for your system?

One piece valves are compact and cost – effective, two – piece valves balance durability and maintenance, and three – piece valves offer superior durability and ease of repair.

Each type has its strengths, so let’s break them down.

One Piece Ball Valves:

- Pros: Affordable and compact.

- Cons: Difficult to repair; often requires full replacement.

- Best For: Low – pressure, moderate applications.

Two Piece Ball Valves:

- Pros: Easier to maintain than one – piece valves.

- Cons: Slightly more expensive.

- Best For: Residential and commercial systems.

Three Piece Ball Valves:

- Pros: Highly durable and easy to repair.

- Cons: Higher upfront cost.

- Best For: High – pressure and industrial applications.

How Do Trunnion Ball Valves Stand Out?

Why are trunnion ball valves ideal for high – pressure systems?

Trunnion ball valves use a solid ball supported by trunnions, making them perfect for high – pressure and large – diameter applications.

They reduce stress on the ball and seats, ensuring reliable performance in demanding environments.

Key Features:

- Pressure Handling: Designed for high – pressure systems.

- Ease of Operation: Reduced torque makes them easier to operate under pressure.

- Applications: Commonly used in oil and gas industries.

Soft Seated vs. Metal Seated Ball Valves: Which Is Better?

Which seating material is right for your application?

Soft – seated ball valves provide tight seals in low – pressure systems, while metal – seated valves excel in high – temperature and abrasive environments.

Soft Seated Ball Valves:

- Pros: Excellent sealing capabilities.

- Cons: Less resistant to high temperatures and abrasives.

- Best For: Low – pressure applications.

Metal Seated Ball Valves:

- Pros: Durable in harsh conditions.

- Cons: May not seal as tightly as soft – seated valves.

- Best For: High – temperature and corrosive environments.

What Are the Latest Innovations in Ball Valve Design?

How have ball valves evolved to meet modern demands?

Recent advancements include split body designs for easier maintenance, stainless steel materials for corrosion resistance, and oversized balls for better flow control.

Key Innovations:

- Split Body Design: Simplifies maintenance and inspection.

- Stainless Steel: Offers superior durability in harsh environments.

- Oversized Balls: Improve flow regulation in full port valves.

Conclusion

Choosing the right ball valve depends on your specific needs. Whether it’s a simple one – piece valve or a high – pressure trunnion valve, understanding the options ensures optimal performance.