A ball valve is a type of valve used to control the flow of liquids or gases in a piping system. It operates by rotating a spherical ball with a hole (the bore) through it, which aligns with the flow path when the valve is open, allowing fluid to pass through. When the ball is rotated 90 degrees by turning the valve handle, the hole is perpendicular to the flow path, effectively blocking the flow.

Here are some key features of ball valves:

- Quick Operation: Ball valves can be opened or closed quickly with a quarter turn of the handle (90 degrees).

- Tight Sealing: They provide a good seal, even after long periods of disuse, which makes them ideal for applications requiring a reliable shut-off.

- Durability: Ball valves are durable and typically have a long service life. They are less prone to wear and tear compared to other types of valves, like gate valves.

- Versatility: Ball valves can be used in various applications, including water, gas, oil, and chemical systems. They are available in different materials, sizes, and configurations to suit specific needs.

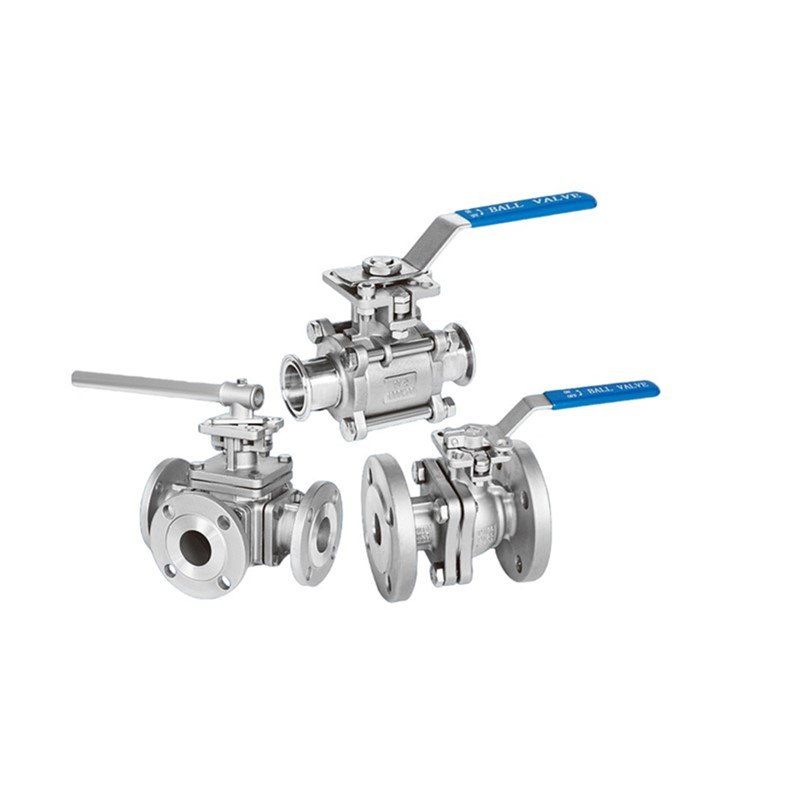

- Types: Ball valves come in different types, including:

- Floating Ball Valve: The ball is not fixed to the valve body and floats slightly to maintain contact with the seat, ensuring a tight seal.

- Trunnion Ball Valve: The ball is fixed in place with a trunnion, which is suitable for high-pressure applications.

- Full Bore Ball Valve: The bore through the ball is the same diameter as the pipe, minimizing flow resistance.

- Reduced Bore Ball Valve: The bore through the ball is smaller than the pipe diameter, creating some flow restriction.

Ball valves are commonly used in industries such as oil and gas, water treatment, chemical processing, and manufacturing due to their efficiency and reliability.